Basic Info.

Model NO.

111AAA-CARBIDE-SEAL-FACES

Type

Cemented Carbide Components

Balance

Balanced

Surface

Finish Ground

Catageory

Carbide Resistance Parts

Materials

Cemented Tungsten Carbide

Grade

Bk8, Rd08n, Rd06n

Hardness

88-90 Hra

Application 2

Pump Wear Parts

Applications1

Oil Filed Wear Parts

Application4

Oil Fields Wear Parts

Application

Valve Parts

Name 2

Cemented Carbide Components

Transport Package

Standard Packing for Cemented Carbide Rods

Specification

20MM TO 300 MM HEIGHT

Trademark

RYDMET CARBIDE

Origin

China

HS Code

8466939000

Production Capacity

2000 PCS /Month

Product Description

The Introduction of the cemented Tungsten Carbide Seal Faces

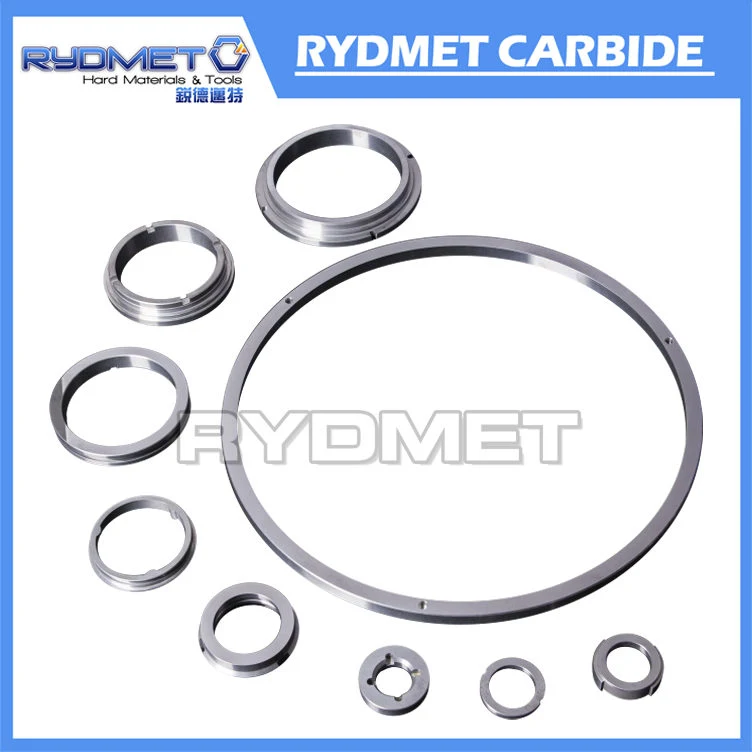

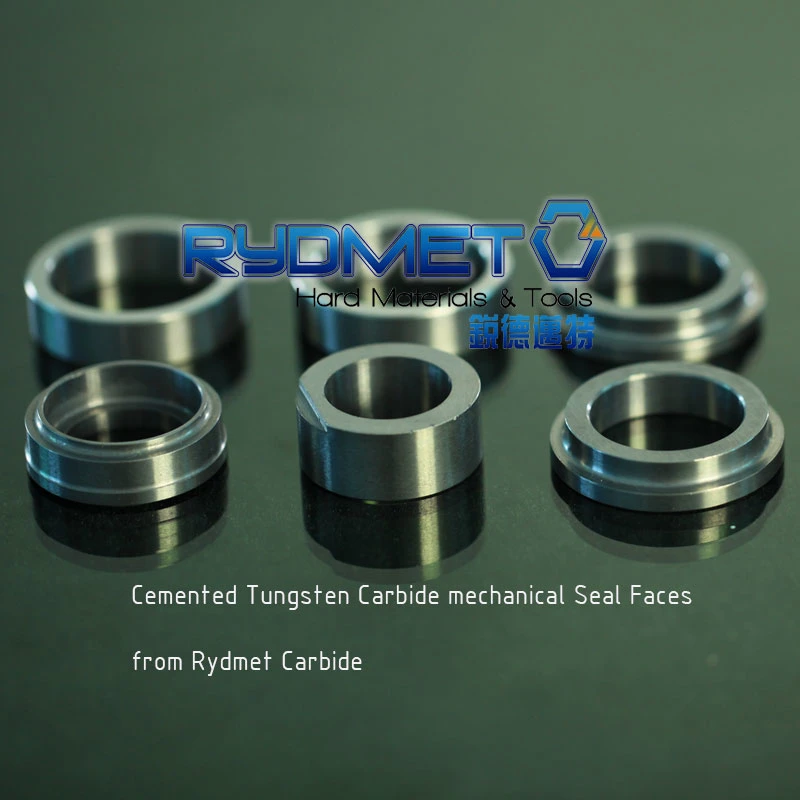

Rymdet Carbide Technologes produces cemented carbide Seal Faces ( Rings) for pumps and mechanical seals, which provide outstanding material performance in corrosive and abrasive environments and in any fluid handling environment, because we can choose the right grade for your applications from our Nickel-Bonded Grade, Cobalt-Bonded Grade or mixed binder bonded Grade. Our engineers can always provide you the right grade for the specific application environment.

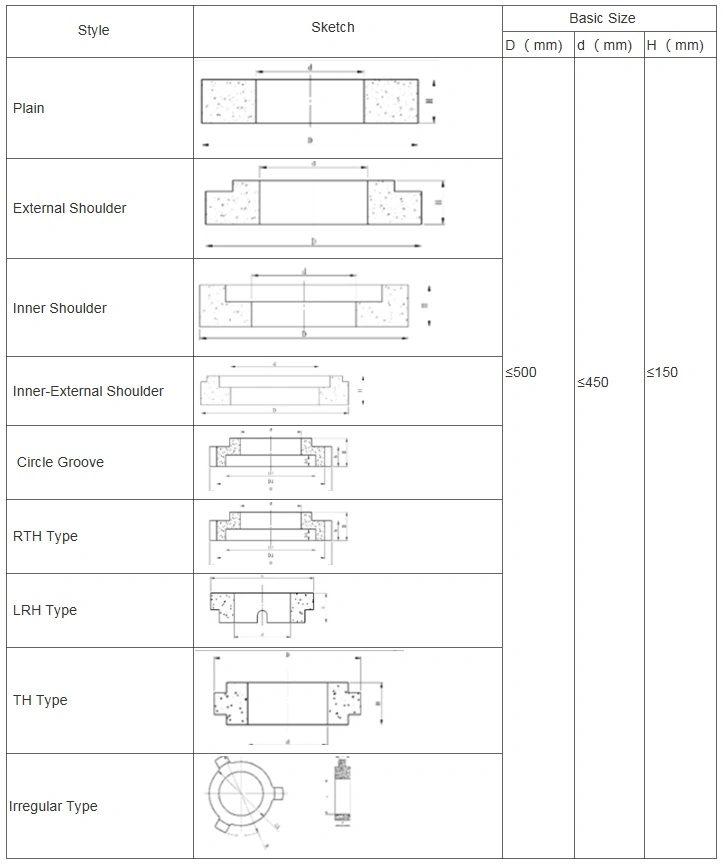

Type of Cemetend Tungsten Carbide Seal Faces

* ** 1 or both surfaces can be with lapping.

*** We can provide the Carbide Seal Faces in Sintered condition with grinding allowance.

** * Custom Sizes can be avaialble as per request.

The Grade Table for Reference:

| Rydmet Standard Carbide Grade Chart for Wear Parts, Components | ||||||

| Grade Code | Binder Content & Type | Hardness (Ra) | Hardness | Density (g/cm3) | Transverse Rupture Strength (TRS) | Grain Size |

| (HV30) | ||||||

| RD06X | 6% Co | 91.5 | 1530 | 14.95 | 2,300 | Fine |

| RD08X | 8% Co | 90.8 | 1450 | 14.75 | 2,500 | Fine |

| RD15X | 15% Co | 88.9 | 1250 | 13.9 | 2,700 | Fine |

| RD06M | 6% Co | 90.3 | 1380 | 14.95 | 2500 | Medium |

| RD08M | 8% Co | 89.5 | 1300 | 14.75 | 2600 | Medium |

| RD011M | 11% Co | 89.2 | 1270 | 14.3 | 2,650 | Medium |

| RD015M | 15% Co | 87 | 1070 | 14.0 | 2,650 | Medium |

| RD06S | 6% Co | 93 | 1790 | 14.95 | 2,600 | Submicron |

| RD10S | 10% Co | 91.8 | 1580 | 14.45 | 2,650 | Submicron |

| RD10C | 10% Co | 88 | 1160 | 14.5 | 2,700 | Coarse |

| FC11C | 11% Co | 87.5 | 1110 | 14.45 | 2,800 | Coarse |

| RD06N | 6% Ni | 90 | 1350 | 14.9 | 1,800 | Medium |

| RD08N | 8% Ni | 88.5 | 1700 | 14.7 | 1,900 | Medium |

| RD10N | 10% Ni | 88 | 1160 | 14.5 | 1,930 | Medium |

| RD12N | 12% Ni | 87.5 | 1110 | 14.1 | 1,950 | Medium |

| RD06N2 | 6% Ni+Cr | 89 | 1250 | 14.2-14.9 | 1,600 | Medium |

| RD08N2 | 8% Ni+Cr | 88.5 | 1210 | 14.0-14.8 | 1,700 | Medium |

| RD06UF | 6% Co | 94 | 2010 | 14.9 | 3,800 | Ultra-fine |