- Overview

- Product Description

- Our Advantages

- Product Parameters

- Detailed Photos

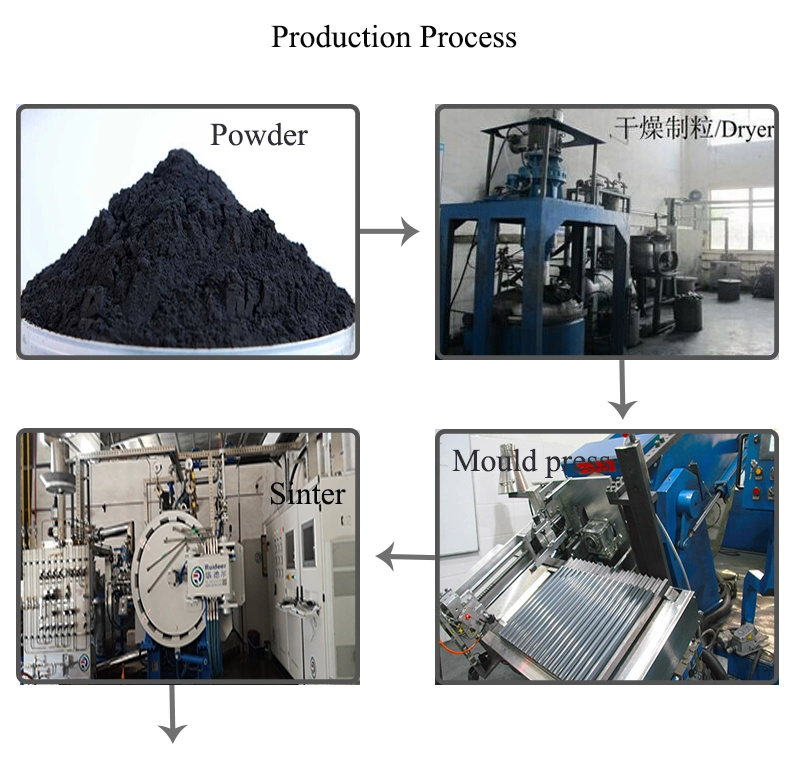

- Production Process

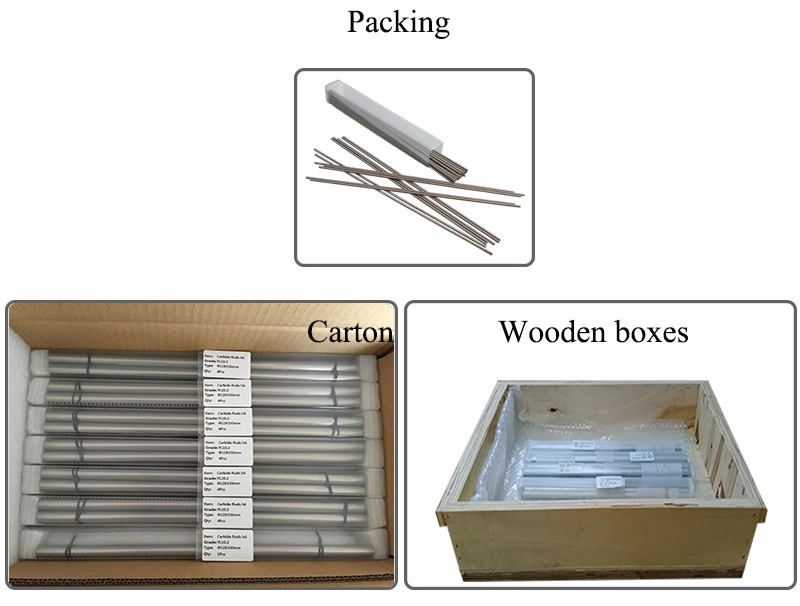

- Packaging & Shipping

Basic Info.

Packaging & Delivery

Product Description

Solid cemented carbide rods are widely used for high-quality solid carbide tools such as milling cutters, end mills, drills or reamers. It can also be used for cutting, stamping and measuring tools. It is used in the paper, packaging, printing, and non-ferrous metal processing industries. Carbide rods can be used not only for cutting and drilling tools but also for input needles, various roll wore parts and structural materials. In addition, it can be used in many fields, such as machinery, chemical, petroleum, metallurgy, electronics and defense industries.

Specialized in tungsten carbide round bars, with an outstanding product line of coolant and solid carbide rod, we manufacture and stock unground and ground carbide rods for you. Our h6 polished chamfered cutting tool blanks are the most popular.

We provide high quality tungsten carbide rods with the following advantages:

Carbide rod characteristics

Made by high quality tungsten carbide superfine powder

Precision equipment with 10MPa HIP-Sinter stove standardized manufacture.

High hardness and high strength

Special advantages: Red hardness, wear resistant, high elasticity modulus, TRS, chemical stability, impact resistant, low dilatation coefficient, heat conduction and electric conduction same with iron.

Special technology: high pressure sintering of high temperature vacuum. Reduce porosity, reduce compactness and mechanical property. Various grade, types and sizes.

Different grade for your reference.

With production experience over 10 years.Senior engineer professional technical service teamWe can provide professional suggestion on products.

1. 100% Virgin raw material.100% virgin raw material.100% inspection before shipment.

2. Sintered in HIP Furnace.High wear resistance.

3. Standard length is 100mm and 330mm,also can be supplied according to customers' request.

4. Shipped on time.Competitive price ,fast delivery and on-time shipment.

| EG GRADE | ISO CODE | GRAIN SIZE(μm) | DENSITY(G/cm³) | HARDNESS | TRS(N/MM) |

| EG06 | K05 | 0.5 | 14.8 | 94.3 | 3800 |

| EG08 | K10 | 0.6 | 14.75 | 92.2 | 3900 |

| YL10.2 | K20 | 0.6 | 14.5 | 91.8 | 4000 |

| EG12 | K30 | 0.5 | 14.1 | 92.5 | 4000 |

| YG15X | K40 | 0.6 | 14.0 | 89.5 | 4000 |

Dimension and Tolerance

| Dimension(mm) | Tolerance of diameter(mm) | Tolerance of length(mm) |

| Min BL-Φ3.0×330 | +0.20/+0.45 | -0/+5.0 |

Max BL-Φ50.0×330 | +0.20/+0.45 | -0/+5.0 |