- Overview

- Product Description

- Product Parameters

- Main features

- Our Advantages

- Company Profile

- You may like

Basic Info.

Nose Application

Profile Molding, Bar Shaped, Pipe Forming, Profile Extrusion

Outlet

Direct Feeding

Pressure of Nose

High Pressure

Metal Mould

Forging Die

After-sales Service

Life Time Technology Support

Type

Tungsten Carbide Nib

Shaping Mode

Compression

Hole Type

Round Mould

Cavity

Multi-Cavity

Surface Treatment

Polish

Customized

Customized

Transport Package

Paper Carbox Box

Specification

Customized

Trademark

DT INDUSTRY

Origin

China

HS Code

82073000

Production Capacity

1000tons/Year

Product Description

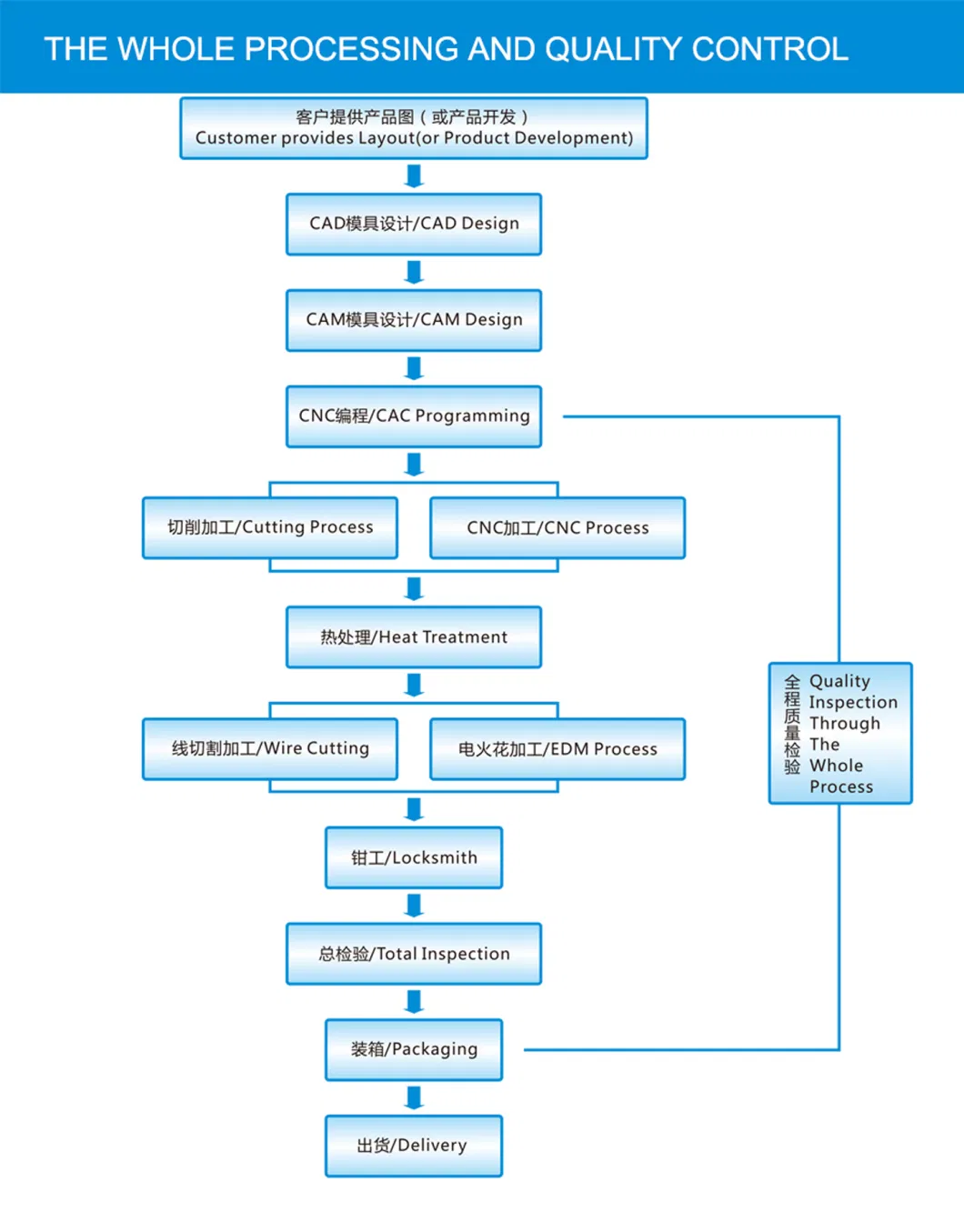

Extrusion die is a tooling for the extruders to produce aluminum profiles, such as window profiles, industrial profiles, door profiles and profiles for curtain wall, etc

H13 ALUMINUM/BRASS/COPPER EXTRUSION DIE

------WELCOME TO CUSTOMIZE------

| Item Name | Aluminum extrusion mold | Output | More than 6 tons of aluminum profile |

| Die Dimension | 60 to 1000mm | Available thickness | 0.6-1.8mm |

| Material | High quality H13 | Die type | Hollow die &Solid die |

| Hardness | HRB hardness 48-52 | Cavities | as you need |

| Way Of Heating | vacuum heat treatment | Delivery Time | Within 15 working days |

| Flow Manifold | Computer simulation | Equipped Plant | Extruder press, die oven, billet furnace |

------WELCOME TO CUSTOMIZE------

| Item Name | Aluminum/copper/brass extrusion mold | Output | More than 6 tons of aluminum profile |

| Die Dimension | 60 to 1000mm | Available thickness | 0.6-1.8mm |

| Material | High quality H13 | Die type | Hollow die &Solid die |

| Hardness | HRB hardness 48-52 | Cavities | as you need |

| Way Of Heating | vacuum heat treatment | Delivery Time | Within 15 working days |

| Flow Manifold | Computer simulation | Equipped Plant | Extruder press, die oven, billet furnace |

| Application | A tooling for the extruders to produce aluminum profiles, such as window profiles, industrial profiles, door profiles and profiles for curtain wall, etc | ||

| MOQ | 1 set | Package | Wooden box or carton box |

Dies with coated mandrels and/or plate inserts:

Even dies with larger diameters can benefit from coating

Small scale-like profiles thanks to exchangeable inserts in a holder

Lower costs due to exchangeable parts

Making tungsten steel mold based on your drawing or your finished products' size.

Inspecting, packing, uploading and shipping service;

Offering all related auxiliary machines, spare parts and consumable tools;

Installing and adjusting machines on site and technology training your labors for operation;

Trial production on site till everything is going well;

On-site technology support if customer needs.

24 hours service online before sales and after sales.

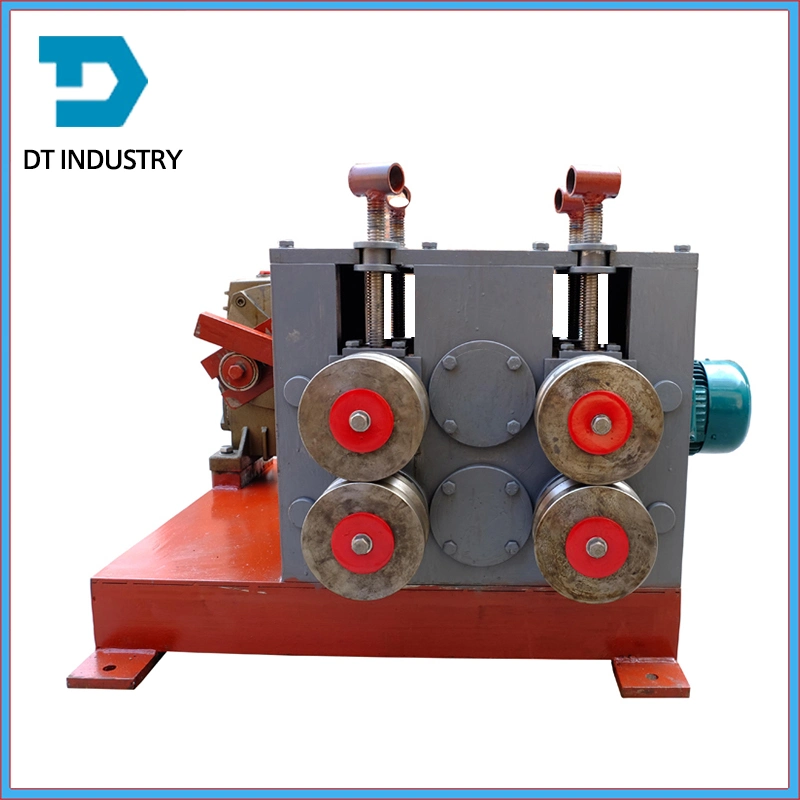

Guangzhou DT Exp. & Imp. Co. Ltd is established in 2012. We are mainly manufacturing machines for non-ferrous metal production.

The main machines are electric melting furnace, holding furnace, continuous casting machine, cutting machine, peeling machine, chamfering machine, drawing machine and, straightening machine. And rolling equipment for steel and brass and copper strip.

Also we are supplying Graphite products for non-ferrous continuous casting production line and tungsten steel mold for extrusion and drawing and peeling production line.

We have a professional and passionate service team, including research and development department, technology support department and international after sales service department.

Our advantages: Qualified Machines; Professional technology, Efficient Service, Worry-free Guarantee.

Our Values: Products as the fundamental, Customers as the center, Create a win-win situation.