Basic Info.

Product Description

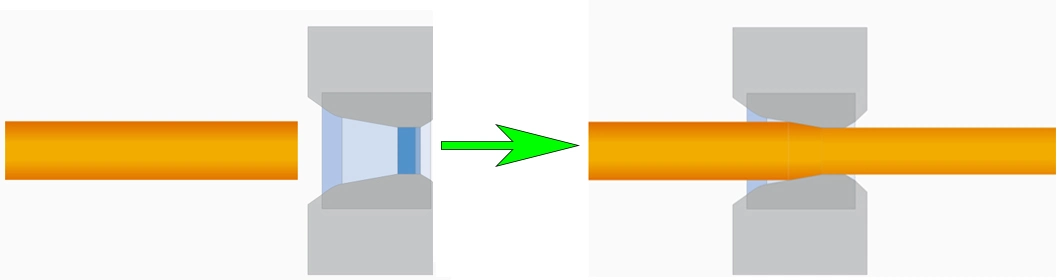

Application Of Tungsten Carbide Drawing dies: Carbide dies are frequently and successfully used in wire drawing (round & shaped), bunching, stranding, guiding, and split die applications. Typically tungstencarbide dies are used for manufacturing wire or rod, generally in highly abrasive and high carbon material areas where PCD dies are not cost effective.

How to select the carbide wire drawing dies:When selecting wire drawing dies, wire material and drawing parameters are important specifications to consider. Typically, wire materials include:copper,stainless steel,aluminum alloy steel,galvanized high-carbon steel,gold,silver,stainless steel,low-carbon steel, molybdenum, nickel.

Drawing parameters include measurements such as inlet diameter, bell radius, entrance angle, approach angle, bearing, and back relief. Elongation, the ratio of length after drawing to the length prior to drawing, is also an important consideration when choosing wire drawing dies.

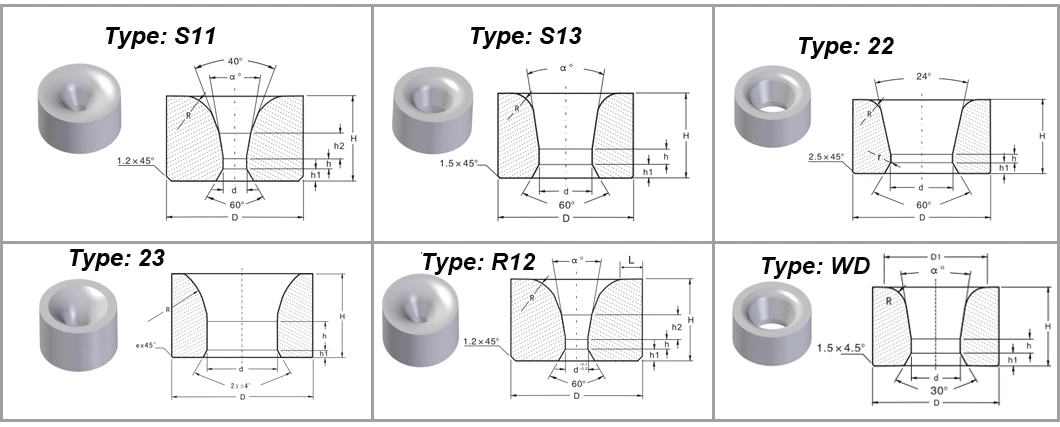

Main types of tungsten carbide drawing dies:

Normal grades for making tungsten carbide dies:

| Grade | Density(g/cm3) | Hardness (HRA) | Bending Strength(N/mm2) | Grain Size(μm) | Applications |

| YG8 | 14.8 | 90 | 2400 | Medium | Good balance between wear resistance and toughness, suitable for making drawing die and other dies in different sizes. |

| YG11 | 14.45 | 88.5 | 2900 | Meidum | Good balance between wear resistance and toughness, suitable for making medium and large sized drawing dies. |

| YG15 | 14 | 87 | 3000 | Meidum | Suitable for making steel pipes, steel rods under high stress & high Compression.Also suitable for making punching dies under heavy impact working condition. |

| YG20 | 13.6 | 85 | 3200 | Meidum | Suitable for making punching dies, like bolts and nuts. |

| YG20C | 13.6 | 83.5 | 3500 | coarse | Suitable for making punching dies like watch parts, steel balls and some forging dies |

| ES40CC | 13.2 | 81 | 3800 | Ultra-coarse | Excellent impact resistance and good heat fatigue performance, suitable making cold heading die, cold punching die, hot forging die, hot stamping die. |

Product to Show:

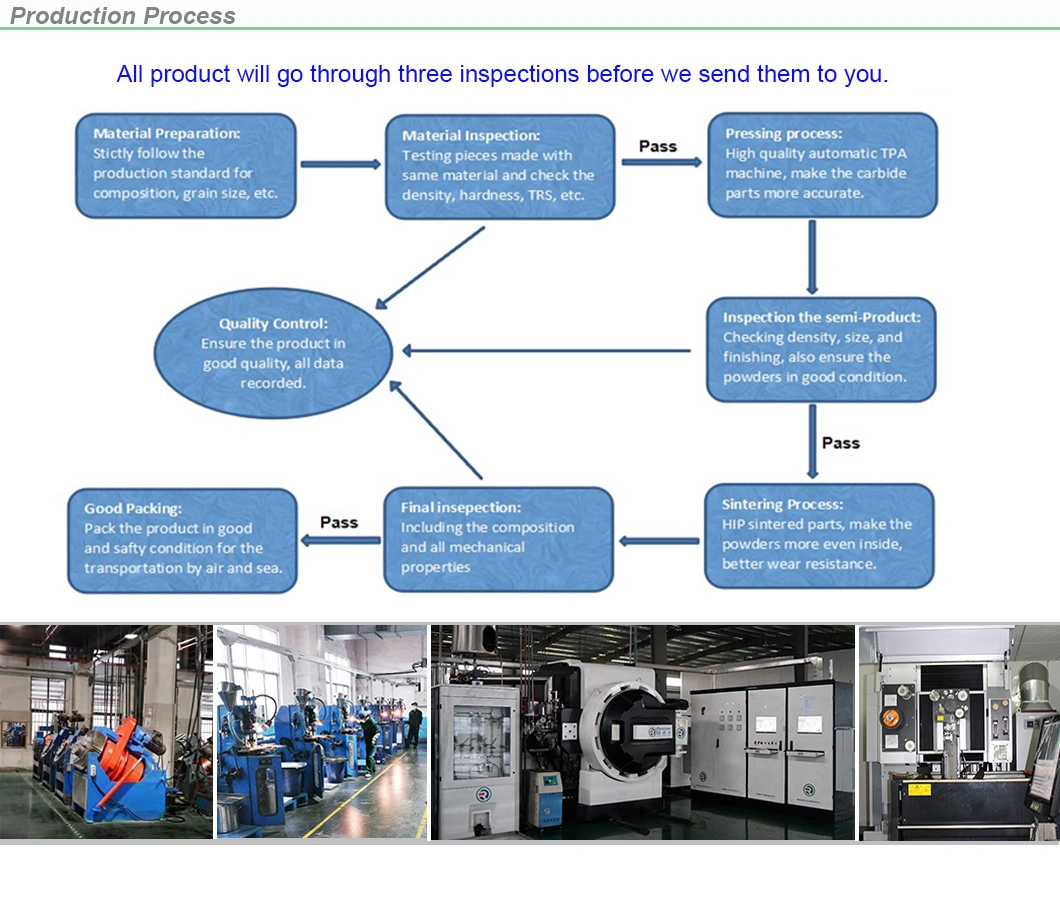

Quality Control System: We always follow the high quality standard for production, from the material preparing to final product ready, all product will go through 3 inspections before we send them to you. Our professional teams will take care of your product and ensure the good and stable quality for all batches.

Our regular product is tungsten carbide tips, carbide inserts, end mills,carbide saw tips,carbide mining parts, carbide rods, plates and stripes.

We also have rich experience for customized product, we make your designs become real product, which perfectly match your need. We have many successful projects on the for our clients in different countries.