- Overview

- Product Description

- Detailed Photos

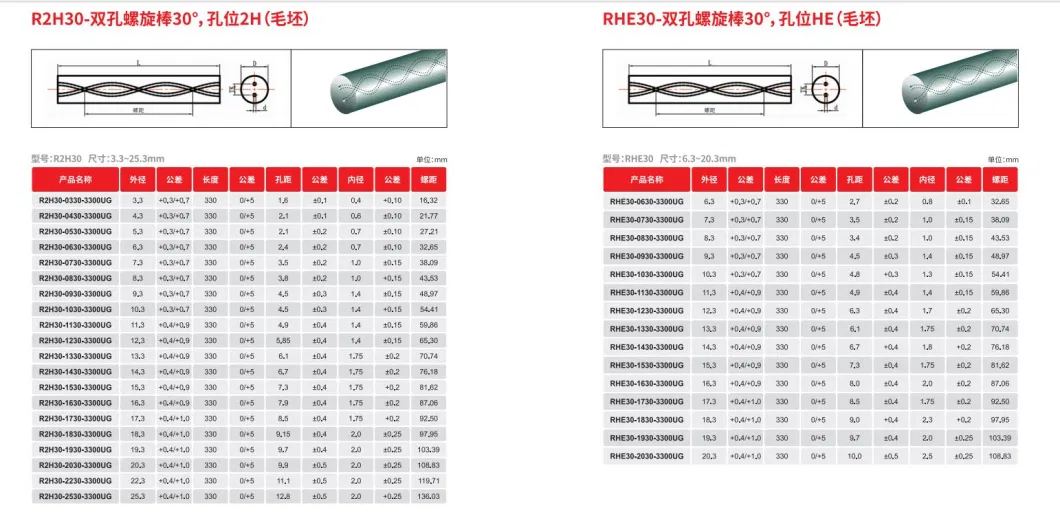

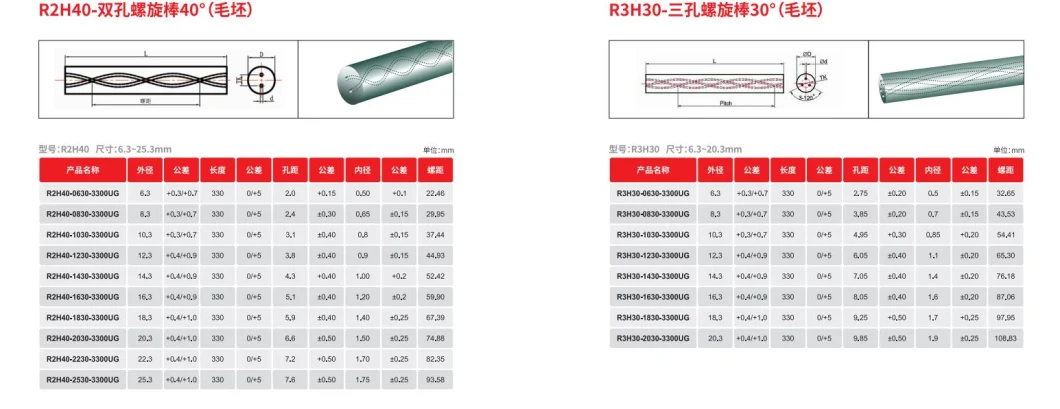

- Product Parameters

- Product detail

- Our Advantages

- Company Profile

Basic Info.

Product Description

The tungsten carbide rods with two coolant ducts is mainly used to make the solid carbide drill. It plays a good heat dissipation role when the coolant flows through the spiral hole in the high-speed processing, and ensures the cutting performance of drill and prolongs the service life of the tool. According to the Angle of the spiral hole, we make rods with two coolant ducts with helix 30°& 40°.

Sunrise Carbide aims to supply the first -class level tungsten carbide rods for cutting tool industry as well as the machining industry. Sunrise Carbide stands for more than 15 years of expertise in tungsten carbide. Patented extrusion technology, innovative grade developments, cylindrical grinding services along with our well trained employee enable us to offer you substantial price-performance advantages for high performance carbides.

| Product name | Solid carbide Rods / Bar / Stick / Columns / Cylinder |

| OD tolerance | h5/h6 |

| Surface fineness | Ra0.2um |

| Sizes | Diameter: Φ3-Φ35mm, Length: 50-330mm |

| Material | Tungsten Raw Materials |

| Physical performance | High Precision, strength, hardness, wear resistance. |

| Application | Carbide rods are mainly used for drill bits, end-milling cutters and winches. |

| Non-standard or Tolerance | Can be customized. |

1. The use of spray drying tower to granulate, make low oxygen content in the raw material, low dirt, the apparent density and the particle fluidity and size are uniform.

2. Use high-precision extruder to mold, make the rod density uniform, size accurate , roundness and straightness high.

3. Use advanced vacuum furnace to sinter, effectively eliminate internal holes and defects, make the rod have good compactness, high strength, and good polishing performance.

4. Use special stress-relieving process to eliminate internal stress of the product and further improve the product strength and improve the microstructure.

5. Processed by the precision grinding machine, the diameter tolerance can reach h5 h6

Zhuzhou Sunrise Hardmetal Tools Co., Limited is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process. All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.