- Overview

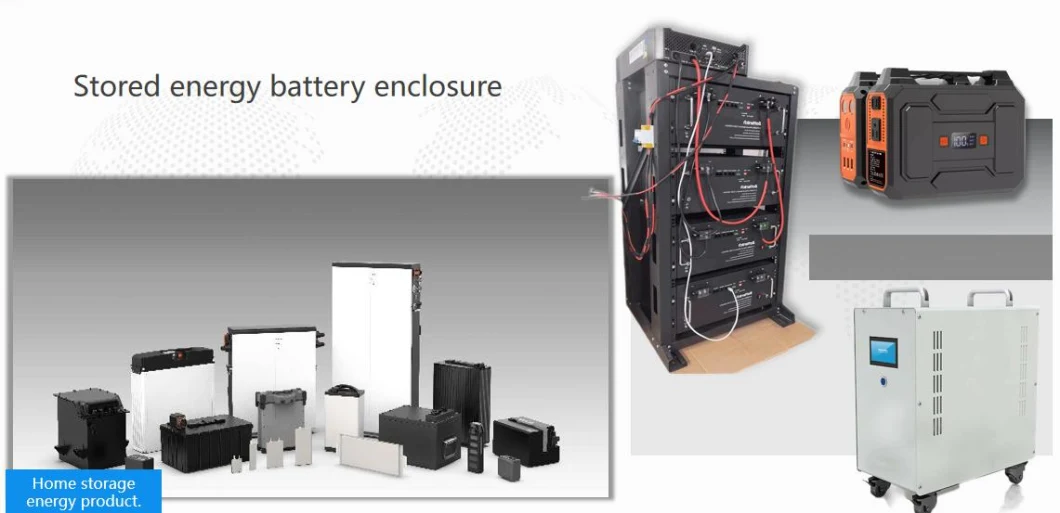

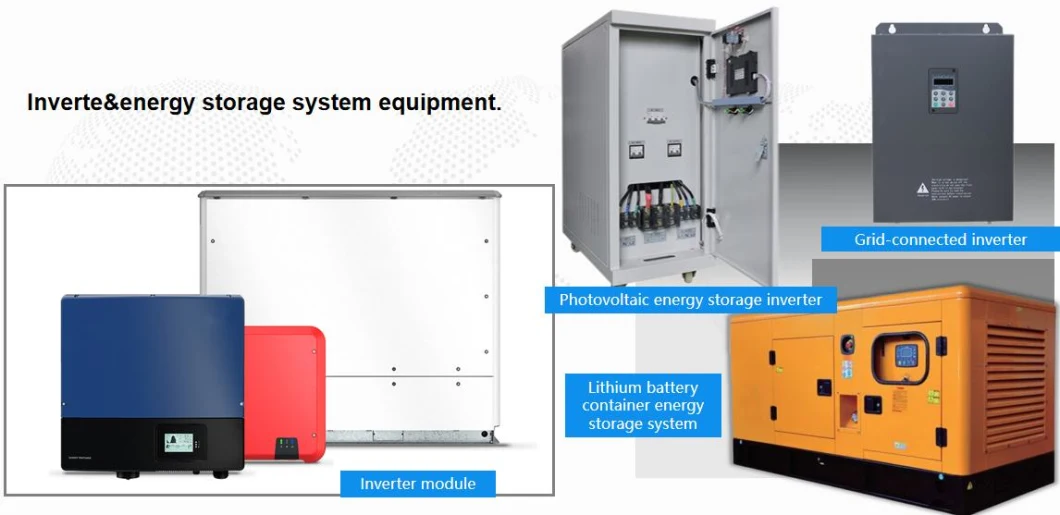

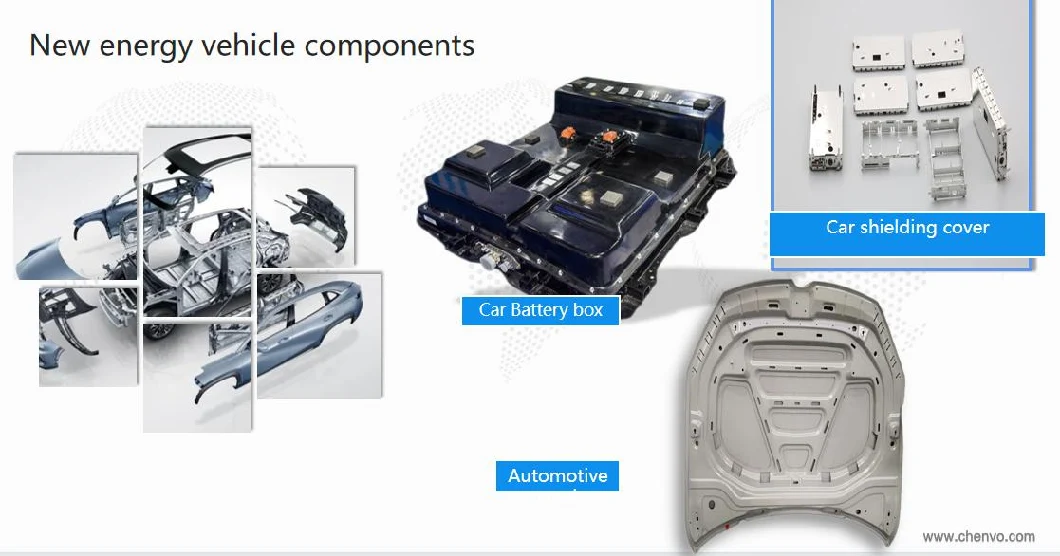

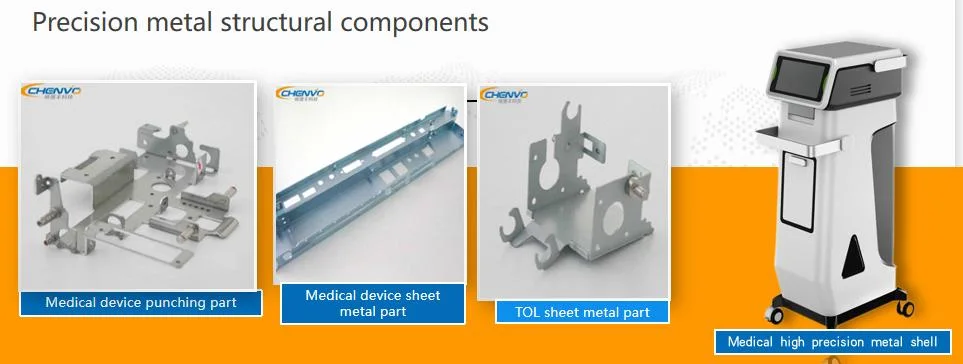

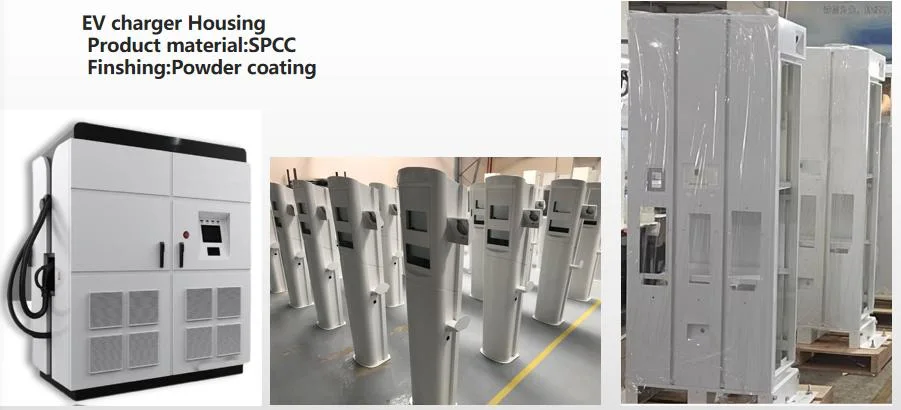

- Product Description

- Detailed Photos

- Certifications

- Packaging & Shipping

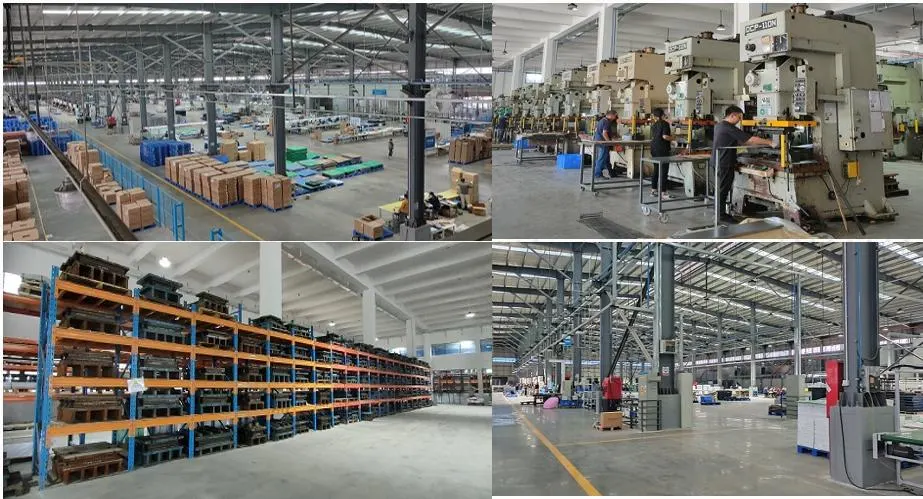

- Company Profile

- Our Advantages

Basic Info.

Product Description

| Item | Description |

| Design/Size | According to customer's drawing or sample |

| Material | Aluminum:6061, 6063, 6082, 7075, 5052, A380 etc. Stainless Steel:SS201, SS301, SS303, SS304, (SS304 FOOD GRADE), SS316,SS316L,SUS430, SS416 Steel: Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. Alloy steel (15Cr,20Cr,42CrMo) and other etc. Brass:HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. Copper,Bronze,Red copper,etc. Titanium: TC4 (TiAl6v4, Gradef5) Plastic:ABS, PC, PE, POM, Delrin, Nylon, plastic, PP,PEI, Peek etc. |

| Process | Cutting,Bending, Turning, Milling, Stamping,Lathing, Welding, etc. |

| Leadtime | 3-7 working days for samples generally, mass production as per detail qty after samples approval. |

| Surface Treatment | Clear Anodized,Color Anodized,Chemical Film, Brushing, Passivating, Polishing, Chroming,Sandblasting, Laser engraving,Zinc plating,Oxide black,Nickel plating,Chrome plating,Carburized,Heat treatment,Painting |

| Test Equipment | CMM, 2D Measurement instrument,Projector,Altimeter,Micrometer,Thread Gages,Hardness Tester, Calipers, Pin Gauge,Salt Spray Test Machine,Concentricity Measuring Instrument Concentricity Measuring Instrument,Spectrometer. |

| Quality Management System | ISO 9001,IATF 16949,ISO14001,ISO45001,ISO13485 |

| Application | Medical equipment manufacturing,computer parts,home appliances parts,electrical equipment parts,electrical appliances parts,electronic products parts,electronic parts,generator parts,alternator parts,dynamo parts,electric generator parts,stationery,power switches,miniature switches, architecture, commodity and A/V equipment.Renewable Energy Data Centers & Infrastructure Utility & Industrial Telecom/Broadband ,Self-Service Kiosk |

| File Format | Solidworks,Pro/Engineer,CAD,PDF,JPG,DXF,IGS |

| Packing | Inner-Plastic bag,Outer -Standard Carton Box,or according to customers' requirements |

| Shipping | By sea, by air, International Express(DHL,FedEx,TNT,UPS). |

| Service | Warm and quick response service by the professional foreign trade team. Size inspection report/Raw material certification/Surface treatment report/Engineering drawing RoHS report/Salt spray test report/Hardness test reort |

Fabrication services for steel, stainless steel, structural steel, alloy, aluminum, brass, bronze, carbon steel, copper, high temperature alloy and perforated metal. Capable of fabricating parts up to 3m length, 3m width, 3m height, 15mm thickness and +/-0.02mm tolerance.Sheet metal stamping parts up to quantity of 20,000units per day. Capabilities include bending, folding, forming, laser cutting, punching, rolling, shearing and welding. Additional services such as consulting, anodizing, plating and painting provided. Prototype and medium to high volume production runs available. Serves the agricultural, automotive, communications, electronics, food processing, medical, mining, railroad, and transportation industries.

2. World-class machines with strong production capacity .

Firstly, Many of our machines are imported with excellent performance, enabling us to produce high precision parts that meet clients' high demand for accuracy.

Secondly,We have 3 factories located in Guangdong and Tianjin, with more than 500 devices in total, allowing us to have high volume output to meet clients' urgent increased quantities

Third,All processes can be done in-house ,this can help us reduce transportation cost and save much time as well as control quality easier.

3. Automatic production line with flexible manufacturing system.

We are the first automatic sheet metal manufacturer in South China,utilizing a flexible manufacturer that help us be more productive and efficient, saving 10%-30% cost compare to our competitors.This allow us to offer our clients very reasonable price.

4. Professional R&D team with 26 years experience and a wide range industry knowledge.

Our R&D team are 260 engineers and designers with extensive experience in various filed.We can help clients to optimize their products' performance and save cost.

5. We have obtained 260 patents on products' safe and performance.

We have certificates of ISO9001, ISO14001, IATF16949, ISO45001, ISO13485 and have been honored with the "National High Tech Enterprise" since 2018.