- Overview

- Product Description

- Product Parameters

- Related products

- Main features

- Our Advantages

- Company Profile

- You may like

Basic Info.

Product Description

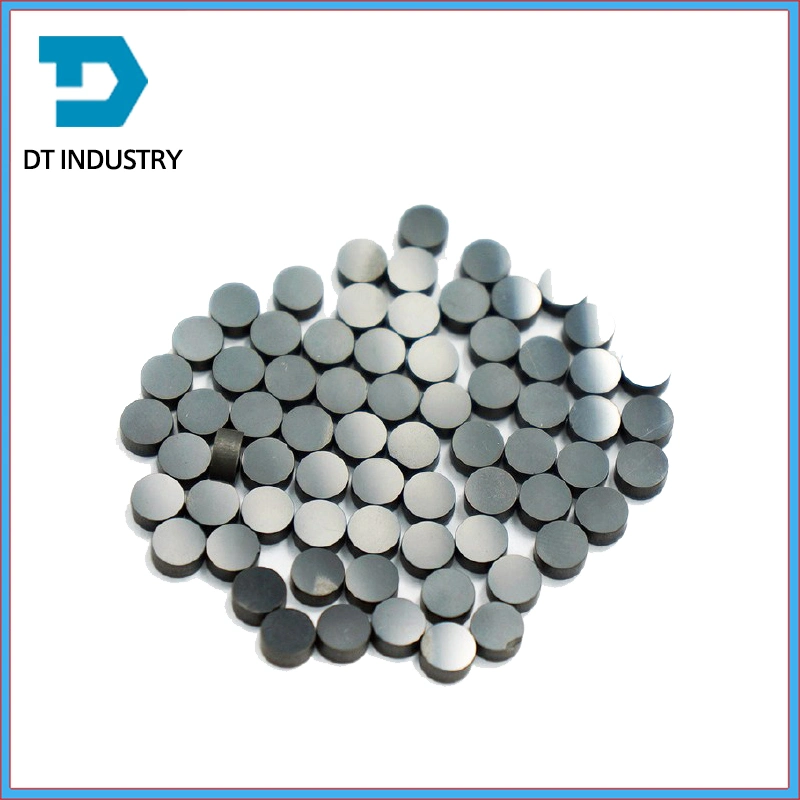

Tungsten carbide strip, mainly by WC tungsten carbide and Co cobalt powder mixed by metallurgical methods through powder, ball milling, pressing, sintering

Tungsten carbide strip is mainly composed of WC tungsten carbide and Co cobalt powder mixed by metallurgical methods through milling, ball milling, pressing, sintering, the main alloy components for WC and Co, different uses of tungsten carbide strip in the WC and Co composition content is not consistent, the use of a wide range of.

One of many materials, because of its shape is rectangular plate (or square) named, also known as carbide strip plate.

Process editing

Pulverization → Formulation according to application requirements → wet grinding → mixing → grinding → drying → screening → adding molding agent → drying → Screening mixed material → granulation → pressing → molding → low pressure sintering → molding (blank) → inspection → packaging → storage.

------WELCOME TO CUSTOMIZE-----

| Model number | density g /cm³ | TRS Mpα | hardness HRA | Performance and application recommendations | Corresponding model | ISOLv. |

| YM6 | 14.9 | 2150 | 90.0 | Good wear resistance for hardwood, processed logs, aluminum profiles, brass bars and cast iron | YG6 | K10 |

| YM6A | 14.9 | 1860 | 92.0 | Higher wear resistance than YG6 for processing hardwood, logs, aluminum profiles, brass bars and cast iron. | YG6A | K10 |

| YM8 | 14.7 | 2320 | 89.5 | Wear and impact resistant for processing hardwood, cork, ferrous and non-ferrous metals | YG8 | K20 |

| YM2T | 14.5 | 2350 | 92.0 | Fine carbide, high wear resistance, high bending strength, high bonding strength, high thermal strength. Processing refractory alloy, stainless steel and high manganese steel | YS2T | K10-K20 |

| YS25 | 13.0 | 2200 | 91.0 | Wear-resistant, high strength, suitable for processing cast iron, metal and non-metallic materials. | -- | |

| YM10X | 14.5 | 2150 | 92.2 | Wear resistance, relatively high strength, suitable for processing cast iron, non-ferrous metals, metal and non-metallic materials. | YL10.2 | K10-K20 |

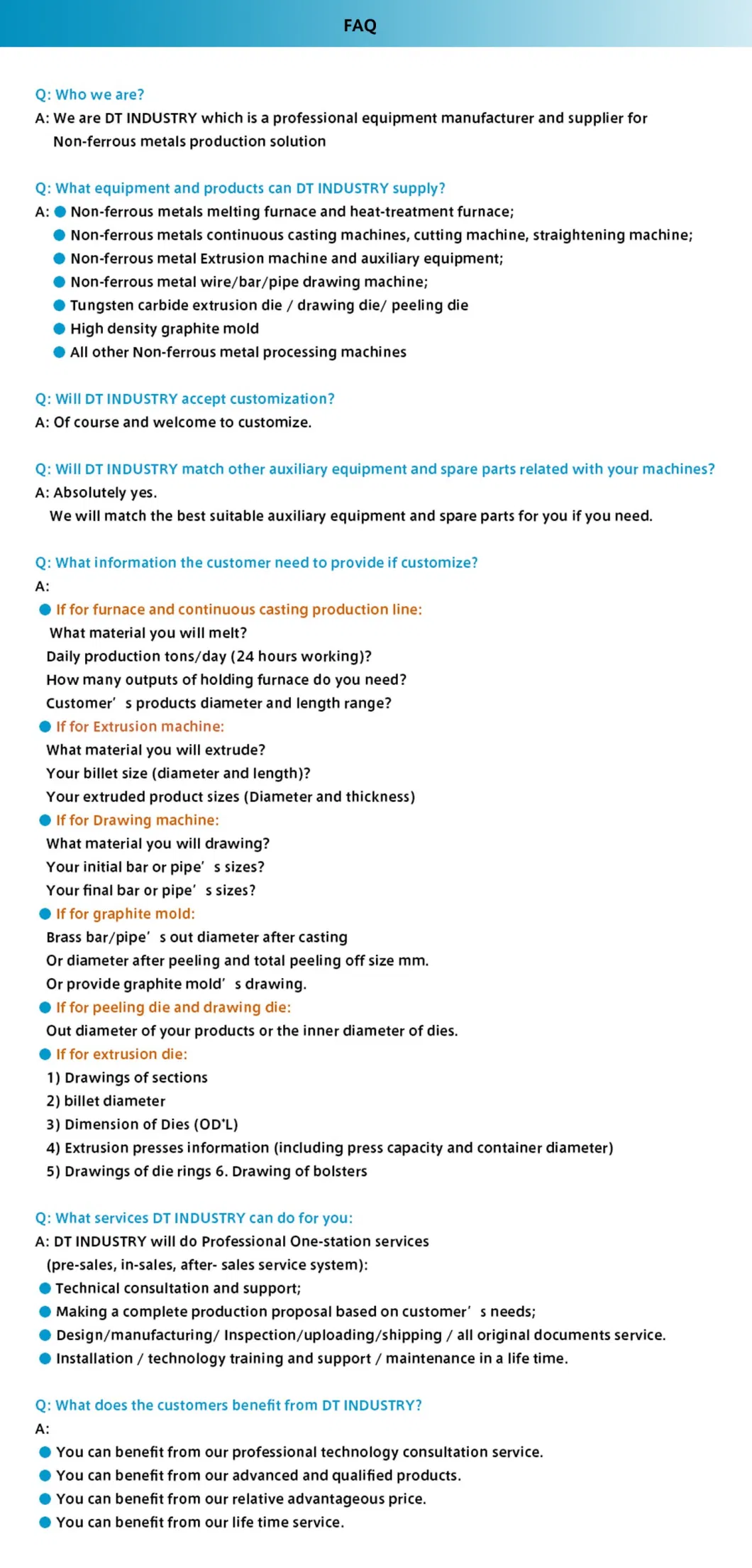

Inspecting, packing, uploading and shipping service;

Offering all related auxiliary machines, spare parts and consumable tools;

Installing and adjusting machines on site and technology training your labors for operation;

Trial production on site till everything is going well;

On-site technology support if customer needs.

24 hours service online before sales and after sales.

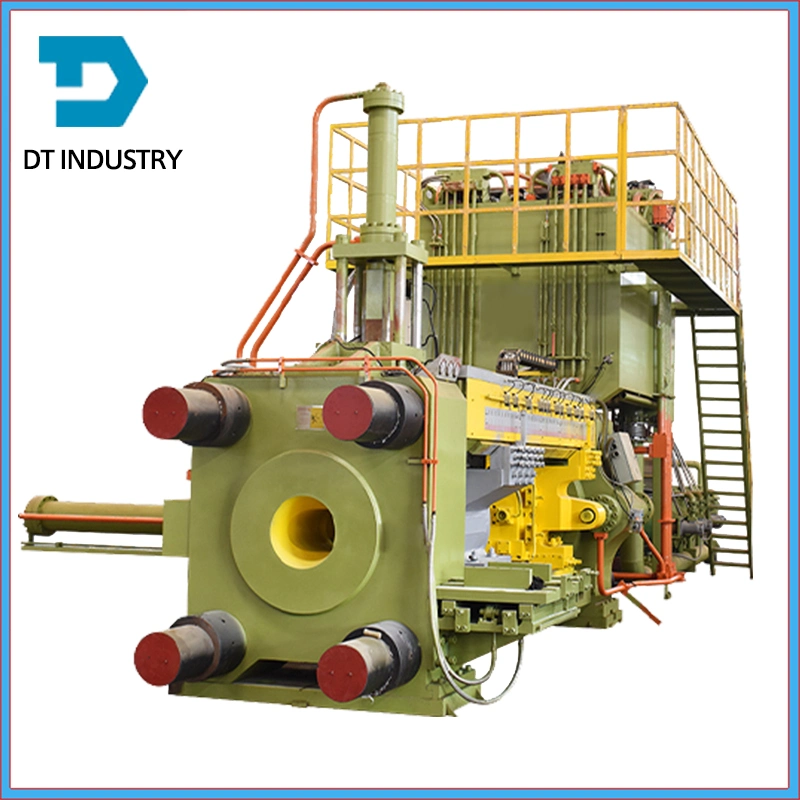

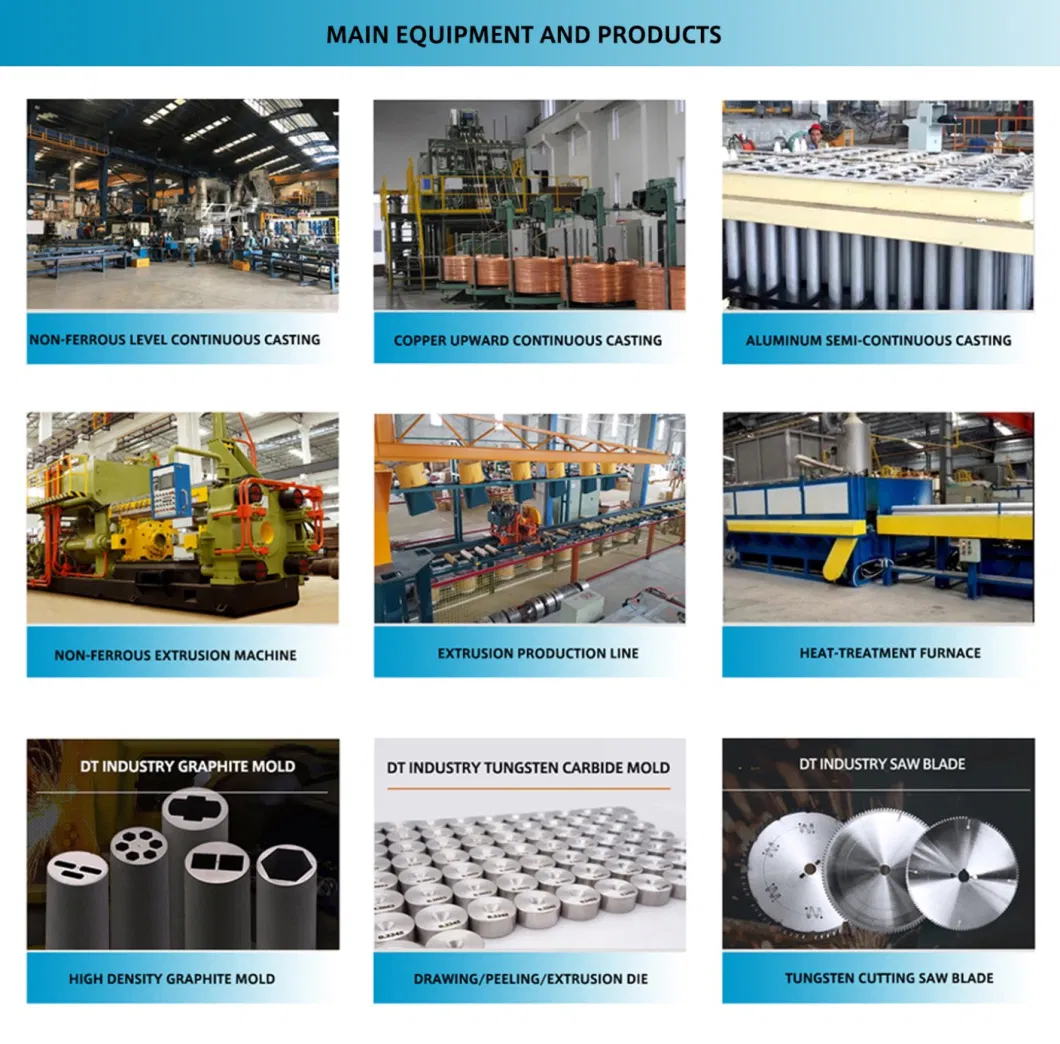

The main machines are electric melting furnace, holding furnace, continuous casting machine, cutting machine, peeling machine, chamfering machine, drawing machine and, straightening machine. And rolling equipment for steel and brass and copper strip.

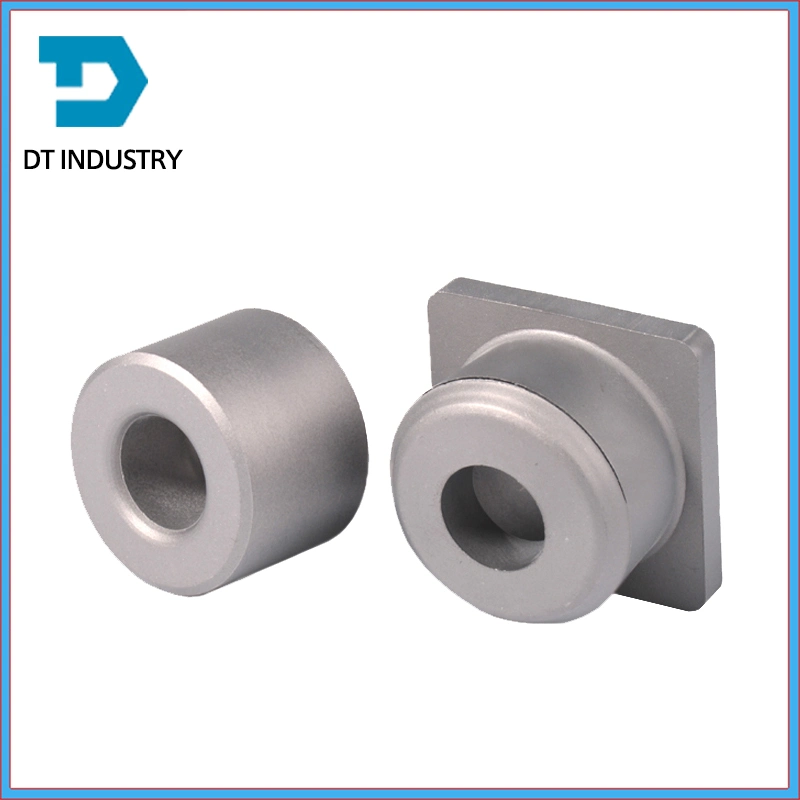

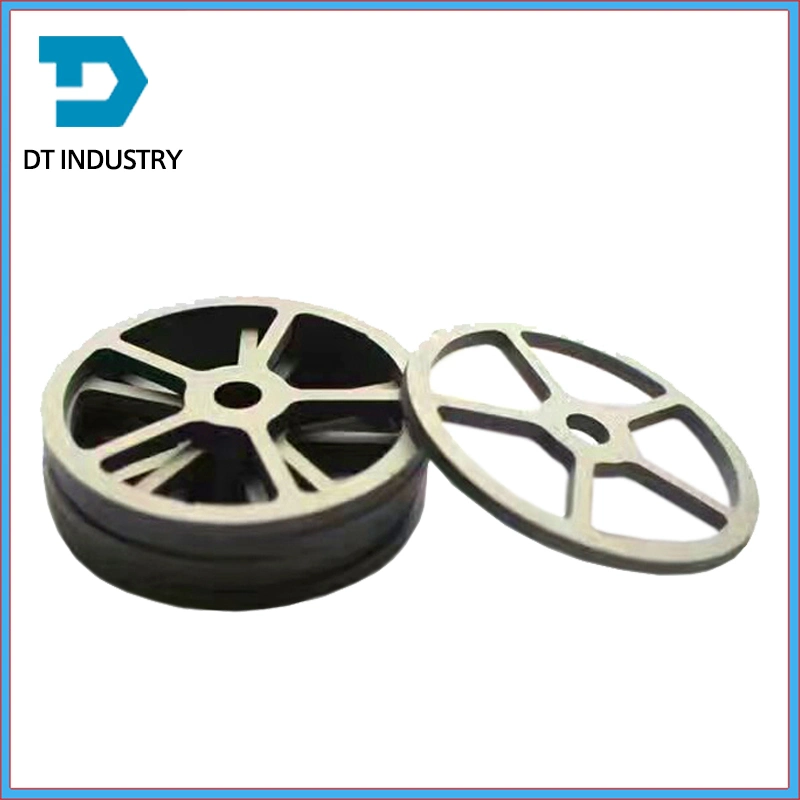

Also we are supplying Graphite products for non-ferrous continuous casting production line and tungsten steel mold for extrusion and drawing and peeling production line.

We have a professional and passionate service team, including research and development department, technology support department and international after sales service department.

Our advantages: Qualified Machines; Professional technology, Efficient Service, Worry-free Guarantee.

Our Values: Products as the fundamental, Customers as the center, Create a win-win situation.