Basic Info.

Model NO.

Seeder 3771

Steel Grade

High Quality Steel

Performance

The Ultra-High Hardness and Strength

Service

Customize ODM OEM

Key Word

Choke Stem and Seat

Industry Applied

Oil & Gas Industry

Transport Package

Standard Package / Customize Packing

Specification

1-300 mm for Length, Width and Thickness

Trademark

Aseeder

Origin

China

HS Code

84819010

Production Capacity

3000 PCS Per Month

Product Description

SEED is the leading manufacturer and exporter of tungsten carbide components, Nozzles radial bearings, as well as provide machining service and hardfacing processes based in China, with a branch office set up in Houston dedicated for North American's market in sales and customer support , we are able to manufacturing all kinds of wear resistance valve parts based on customer's drawing and material requirement, support hardfacing process based on customer's technique requirement, since most of our products are customized and not suitable to show for other customer, welcome to contact us for OEM service.

PTA/HVOF /Boriding/ Sintering /wellhead choke valve assembly with API approvals

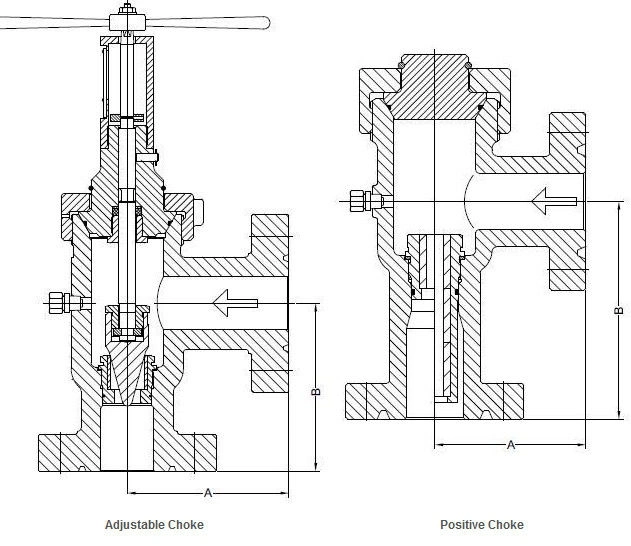

As the most common parts used in the positive choke valve to control the flow, Aseeder provided Choke bean and Choke Stem has features as below:

Same as Cameron type H2 big john choke bean, SS410 Stainless Steel lined with Tungsten Carbide (C10 or C25) , Highly efficient anti-corrosive and abrasive wear.

Same as Cameron type H2 big john choke bean, SS410 Stainless Steel lined with Tungsten Carbide (C10 or C25) , Highly efficient anti-corrosive and abrasive wear.

PTA/HVOF /Boriding/ Sintering /wellhead choke valve assembly with API approvals

As the most common parts used in the positive choke valve to control the flow, Aseeder provided Choke bean and Choke Stem has features as below:

![]() Specific diameter,:Graduations of 1/64-132 inch, can be as large as 3 inches.

Specific diameter,:Graduations of 1/64-132 inch, can be as large as 3 inches.

![]() QPQ treatment : surface hardness Property much improved.

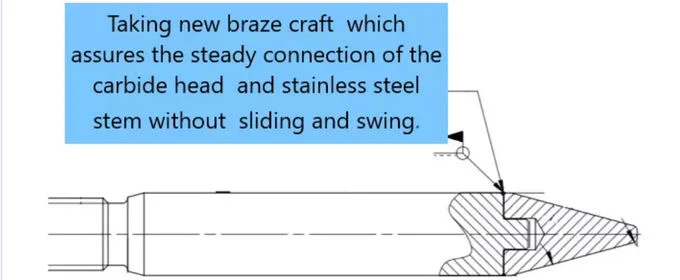

QPQ treatment : surface hardness Property much improved.![]() New braze craft applied to keep more steady connection, see the diagram:

New braze craft applied to keep more steady connection, see the diagram:

Product Parameters:

| TYPE | Dimension (mm) | Material Recommended | |||||

| D | d1 | d | L | α° | |||

| Valve Core | 52-80 | 40-70 | 10-40 | 75-120 | 10-45 | Tungsten+Cobalt | |

| TYPE | Dimension (mm) | Material Recommended | |||||

| D | d | L | |||||

| Valve Seat | 75-100 | 55-70 | 20-80 | Tungsten+Cobalt | |||

Choke stem and seat are the key parts for ajustable choke valves in wellhead equipment . Assembled with tungsten carbide tips and SS410 body .

Tungsten Carbide Materials Grade As Below:

| Aseeder Grade | Co (Wt %) | Density (g/cm3) | Hardness (HRA) | TRS (≥N/mm²) |

| ZY11-C | 9.0-11.0 | 14.33-14.53 | 88.6-90.2 | 2800 |

| ZY15-C | 15.5-16.0 | 13.84-14.04 | 85.6-87.2 | 2800 |

| ZY15X | 14.7-15.3 | 13.85-14.15 | ≥89 | 3000 |

| ZY20 | 18.7-19.1 | 13.55-13.75 | ≥83.8 | 2800 |

| ZY06X | 5.5-6.5 | 14.80-15.05 | 91.5-93.5 | 2800 |

| ZY08 | 7.5-8.5 | 14.65-14.85 | ≥89.5 | 2500 |

| ZY09 | 8.5-9.5 | 14.50-14.70 | ≥89 | 2800 |

| ZY10X | 9.5-10.5 | 14.30-14.60 | 90.5-92.5 | 3000 |

32,000 Square Meters Factory:

Machining Facilities:

Seed Team: