- Overview

- Product Description

- Company Profile

- Equipment

- Certifications

- FAQ

Basic Info.

Packaging & Delivery

Product Description

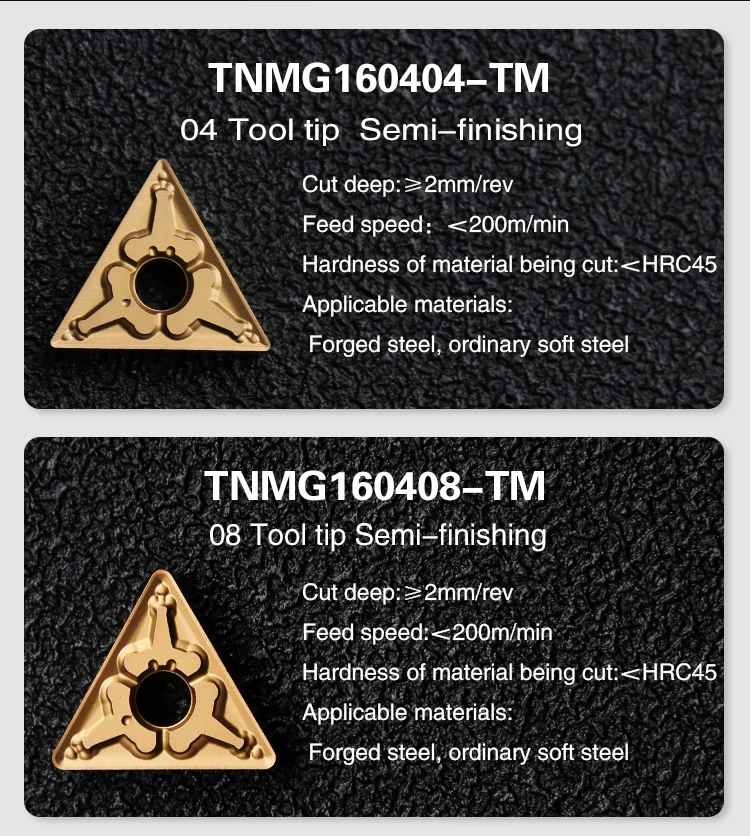

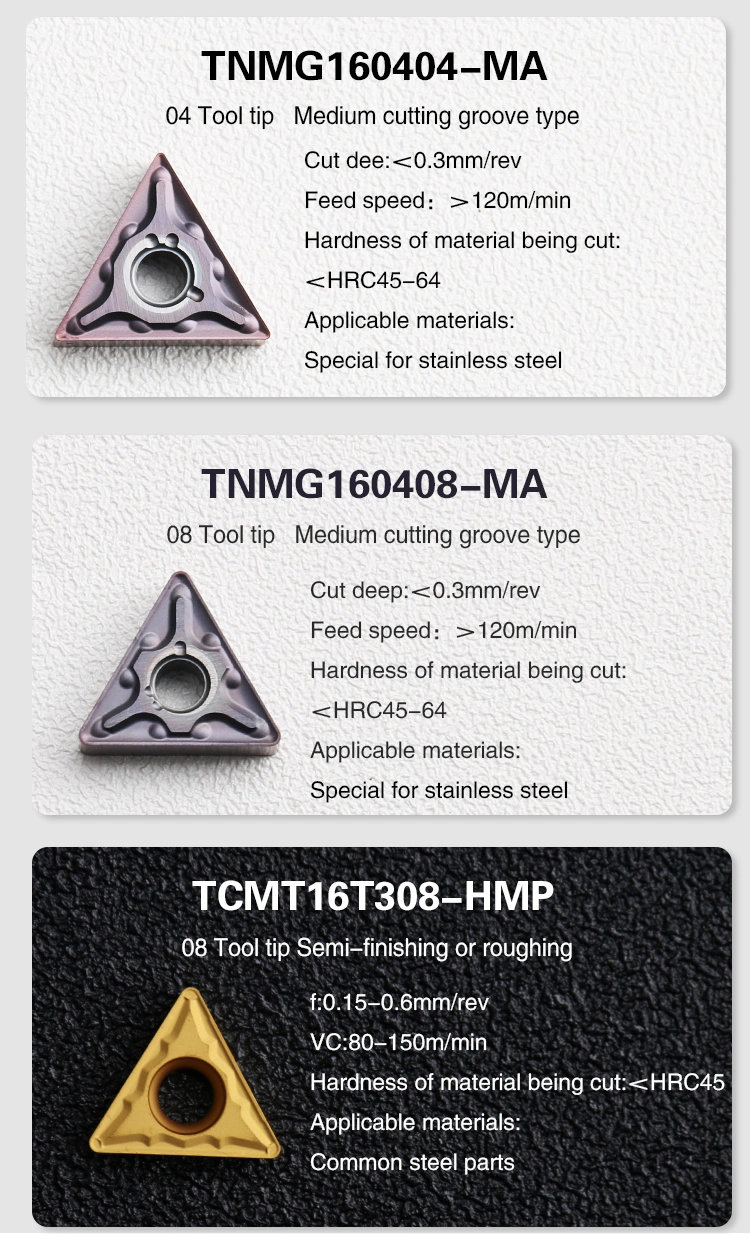

| Insert Model | Cut deep | Feed speed | Hardness of material being cut (<) | Applicable materials |

TNMG160404-TM | ≥2mm/rev | <200m/min | HRC45 | Forged steel,ordinary soft steel |

TNMG160408-TM | ≥2mm/rev | <200m/min | HRC45 | Forged steel,ordinary soft steel |

TNMG160404R-M | ≥2mm/rev | <200m/min | HRC45 | special for steel parts |

TNMG160404R-M | ≥2mm/rev | <200m/min | HRC45 | special for steel parts |

| TNMG160408R-M | ≥2mm/rev | <200m/min | HRC45 | special for steel parts |

TNMG160404L-M

| ≥2mm/rev | <200m/min | HRC45 | special for steel parts |

| TNMG160408L-M | 2mm/rev | <200m/min | HRC45 | special for steel parts |

| TNMG160404-MA | <0.3mm/rev | >120m/min | HRC45 | special for steel parts |

| TNMG160408-MA | <0.3mm/rev | >120m/min | HRC45 | special for steel parts |

FAQ about the insert :

1. Severe wear on the rear blade surface

Impact: Gradual change of workpiece size or decrease of surface finish

Reason: The line speed is too high, reaching the tool life

Measures: Adjust the processing parameters, such as lowering the line speed or changing to inserts with higher wear resistance.

2.The problem of collapsing knives

Impact: Sudden change of workpiece size or surface finish, burr on production spark surface

Reason: The parameter setting is not suitable, the blade material is not selected correctly, the workpiece rigidity is not good, the blade clamping is not stable.

Measures: Check whether the parameters are suitable, select the corresponding tool according to the workpiece material

3. Severe fracture

Impact: Unpredictable and sudden occurrence, resulting in toolholder material scrap or workpiece failure and scrap

Reason: Wrong processing parameter setting, vibration tool workpiece or insert is not clamped in place

Measures: Set reasonable processing parameters, reduce the amount of feed and reduce cutting, select the corresponding processing insert, and strengthen the rigidity of the workpiece and insert

4.Chip accumulation at the tool tip

Impact: Inconsistent size of workpiece, poor surface finish, adherence to workpiece surface

Fuzz or burr

Reason: Cutting speed is too low, feed is too low blade / not sharp enough

Impact: Improve the cutting speed, feed, use a higher sharpness of the insert

Shandong Ounuowei CNC Tool Co., Ltd, founded in 2014,We mainly produces various of CNC tool systems such as CNC tool holders, live centers, spring collets, boring heads, milling chucks,drill chucks, pull studs and other machine accessories which are sold to Australia, South Africa, United States,Russia, Europe, Middle Asia, South America and Southeast Asia, and more than fifty countries and regions.Welcome to visit our factory.

Our Services:

1. Guarantee quality which mainly embodied in real accuracy.

2. Huge production capacity to ensure in time delivery

3. Manufacture that can accept OEM service.

4. Professional sales team and engineers.

5. Sufficient experience in domestic and international sales

6. Prompt reply which response in 15 minutes

7. Never stop in innovating and improving

Our mission:

making CNC machining more efficient

manufacturing wonderful Chinese CNC tools

Our sense of value:

Customers is the first, staffs is the second, shareholders is the third;

Market oriented and customer centric;

Charity begins at home,but should not end there.

Treat suppliers as brothers and seeking mutual benefit;

Stick to innovation and sustainable development;

Teamwork and share duties and benefits.

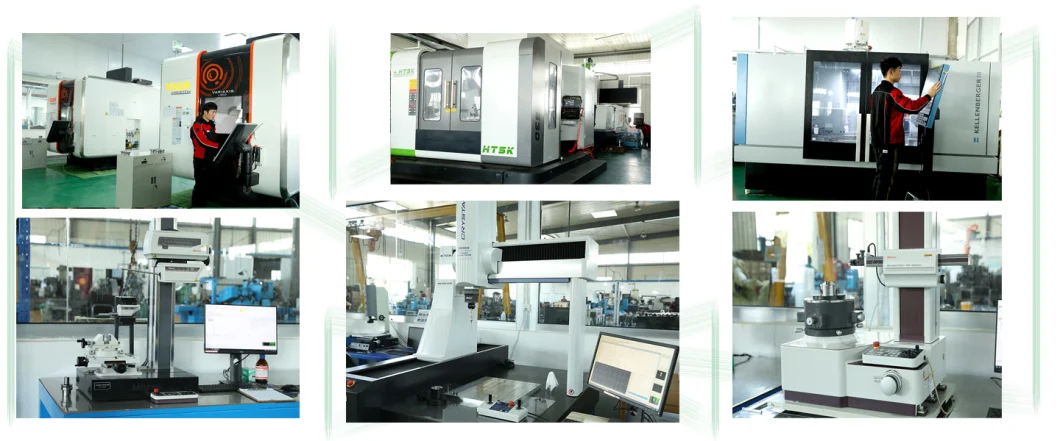

The company has more than 150 sets of production equipment and testing equipment, such as Japanese Mazak CNC lathes, Mazak five-axis machining centres, Swiss Klingberg CNC compound grinding machines, Japanese Mitutoyo three coordinates, cylindricity meters, contouring meters and German Daibo toolholder inspection tools.

Our company has passed ISO9001 quality system certification,SGS Certification ,Tuv certification

1.Are you a factory or trading company ?

We are a manufacturer ,and we also have our own trading company ,we have professional R&D team .sale team .We can provide you the best quality goods and the perfect service .2.Could you provide non standard products ?

Yes we can.we can also make and supply the goods as delivered samples or drawing .

3.What is the advantage about your company ?

Our company has professional team and professional production line .

4.Why should I choose your products ?

Our products are high quality and good price

5.Any other good service your company can provide ?

Yes ,we can provide good after-sale and fast delivery

6.How can we guarantee quality ?

We follow our QC manual and inspect all data of our products 100%