Basic Info.

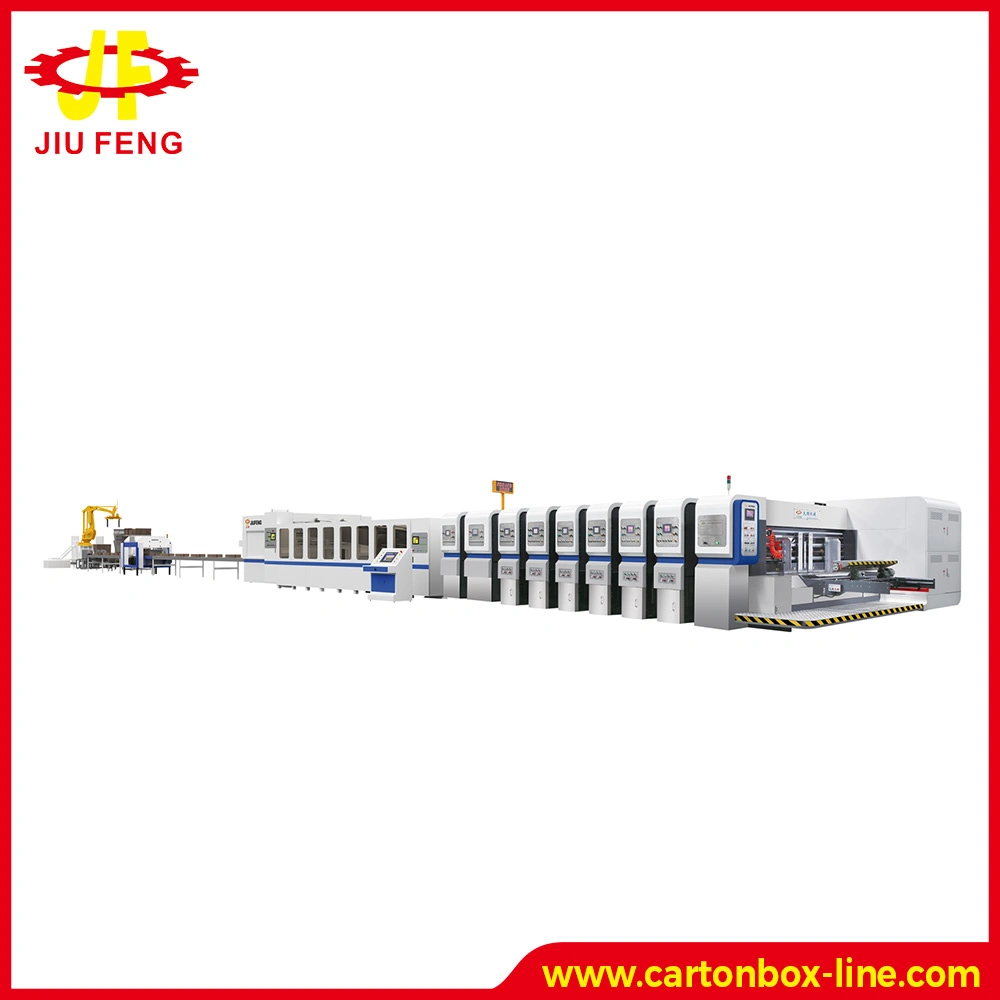

Product Description

SPECIFICATIONS

| MODEL | JF0920 | JF1224 |

| Max. Machine Speed (sheets/min) | 250 | 200 |

| Max. Feeding Size (L * W) (MM) | 900*2000 | 1200*2400 |

| Min. Feeding Height (MM) | 350 | 400 |

| Min. Folding Size (MM) | 300*150 | 280*150 |

| Suitable For Boardsheet | E-AB Flute | |

PERFORMANCE CHARACTERISTICS:

1. Four shaft lead edge vacuum transfer feeding system, the pressure of suction is adopted frequency control, which can apply for difference size and bending of cardboard.

2. The main drive system is adopted US EMERSON servo control. It can make more accuracy and improve the service life of the machine

3. It is using precise screw with linear guide, which is prevent the cutting holder locked with cutting shaft and make it more accuracy.

4. Die cutting rubber roller is adopted Emerson servo drive with mechanical speed compensation.

5. With No-key connection ring. There will be no clearance after long time using, so that it has high precision for positioning and exact overprint.

6. The transmission gear is made of high quality alloy steel, which is processed by tungsten carbide and treated by heat treatment and Rockwell hardness of 58-62 degrees.

7. With doctor blade interchange rubber roller structure; Change the mechanical configuration more flexible.

8. Paper feeding wheel adopts rack type with quick adjusting structure without wrench.

9. The pressure of 3ply 5ply 7ply is setting by our patent high precision minor pressure adjustment,which work in with PLC and the accuracy is +- 0.01.

ELECTRICAL CONTROL SYSTEM FEATURES:

2. The machine with order memory, easy to change the order

Dongguan Jiufeng Carton Machinery Co., Ltd. is a pluralistic carton machinery manufacturing company dedicated to carton machine research, production and sales, all while providing top of the line products and one-stop services for customers.

Jiufeng Carton Machinery was established in 1996 as a small start-up, and through hard work, dedication and loyal customers, we now employ more than 50 people, including 10 research and development team members, and 12 science and technology experts to make full use of raw materials and new technologies to ensure the best performance of all products. Jiufeng's plant area has exceeded 10000 m² and includes more than 10 production lines used to produce various products, including a full set of carton equipment such as Hidepack corrugated box making machines (high definition printing, drying, slotting, die cutting and gluing ), D-Star corrugated box making machines (vacuum heat transfer, printing, slotting and die cutting), G5 corrugated box making machine(high speed printing, slotting, and die cutting), servo control system semi-automatic carton stitcher, automatic and semi-automatic rotary slotting creasing machine, large roller printing machine (multi-color), semi-automatic carton gluer, BFY series of blade slitter scorer, and nailing machines. These products are widely used in carton cutting, carton binding, carton printing and color printing.

Jiufeng Carton Machinery has exported products to more than 10 countries in East Africa and Southeast Asia, demonstrating that our high quality products and professional, individualized sales services have earned the trust of our customers and kept them coming back for more.

Our Services

According to the customer's requirement, we will arrange one technician to help you to install the machine and train the worker, but all the expenses like round-trip air tickets, accommodation, meals and salary USD80/day, incurred therefrom shall be born by the buyer.

Warranty

Warranty: one year. The manufacturer will send the buyer new parts ( no intentional damage). However, the courrier should be covered by the customer. Please note that the belts are excluding the one year's warranty.

FQA:

1. What is the machine warranty?

one year.

2. Does your machine with CE certificate?

Yes.

3. What's the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment L/C.

4.What is the production time while placing order?

About 30 days.

5. What is the delivery time?

Within 30 days after get the payment.

6. Does the packing strong?

Yes, of course! All of our export packings is with strong wooden pallets, all are confirmed to export packing standard.

7. Are you manufacturer?

Yes, we are manufacturer, and we have been in this field for more than 10 years.

8. Do you have a stock product to sell?

Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, so we need a custom one for you, and your order will be highly attention to manufacture.

9. How about after-sales service process?

When your machine has a problem, contact your sales and we will solve your problem as soon as possible.

10. Do you inspect the finished products?

Yes, we have QC department, they will inspection the machine before shipping, to ensure there is nothing problem of the machine.

11. Do you have your technical team?

Yes, we have our own technical team and we have our own patents. And we can custom the machine as customer want.