Basic Info.

Model NO.

YG8

Match Ball Sizes2

10mm

Usage

as Milling Jar

Surface

Grinding and Polished

Transport Package

25kg. Carton

Specification

60ML

Trademark

ZZUP

Origin

Zhuzhou, Hunan, China

HS Code

8209009000

Production Capacity

10000000PCS/Month

Product Description

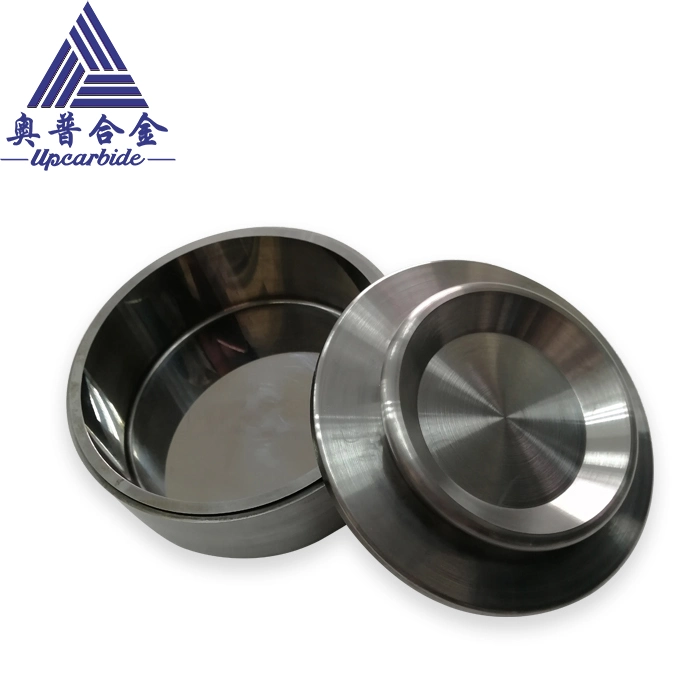

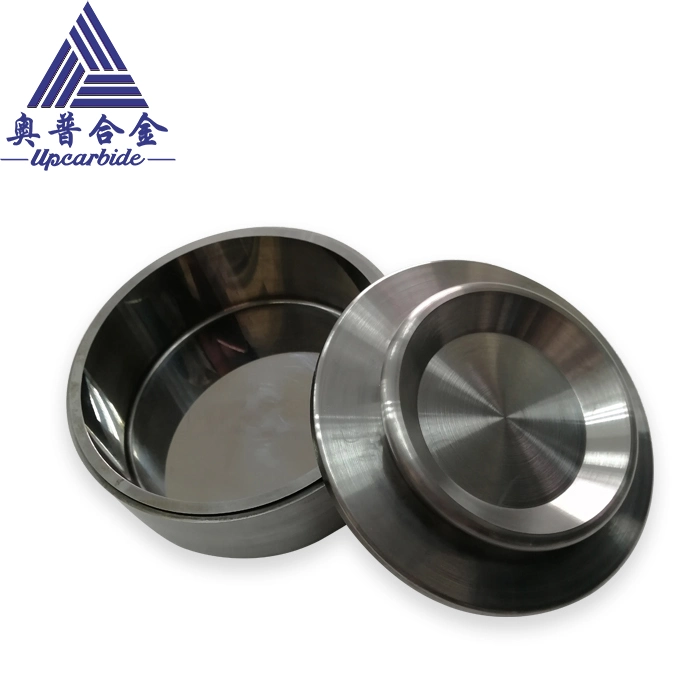

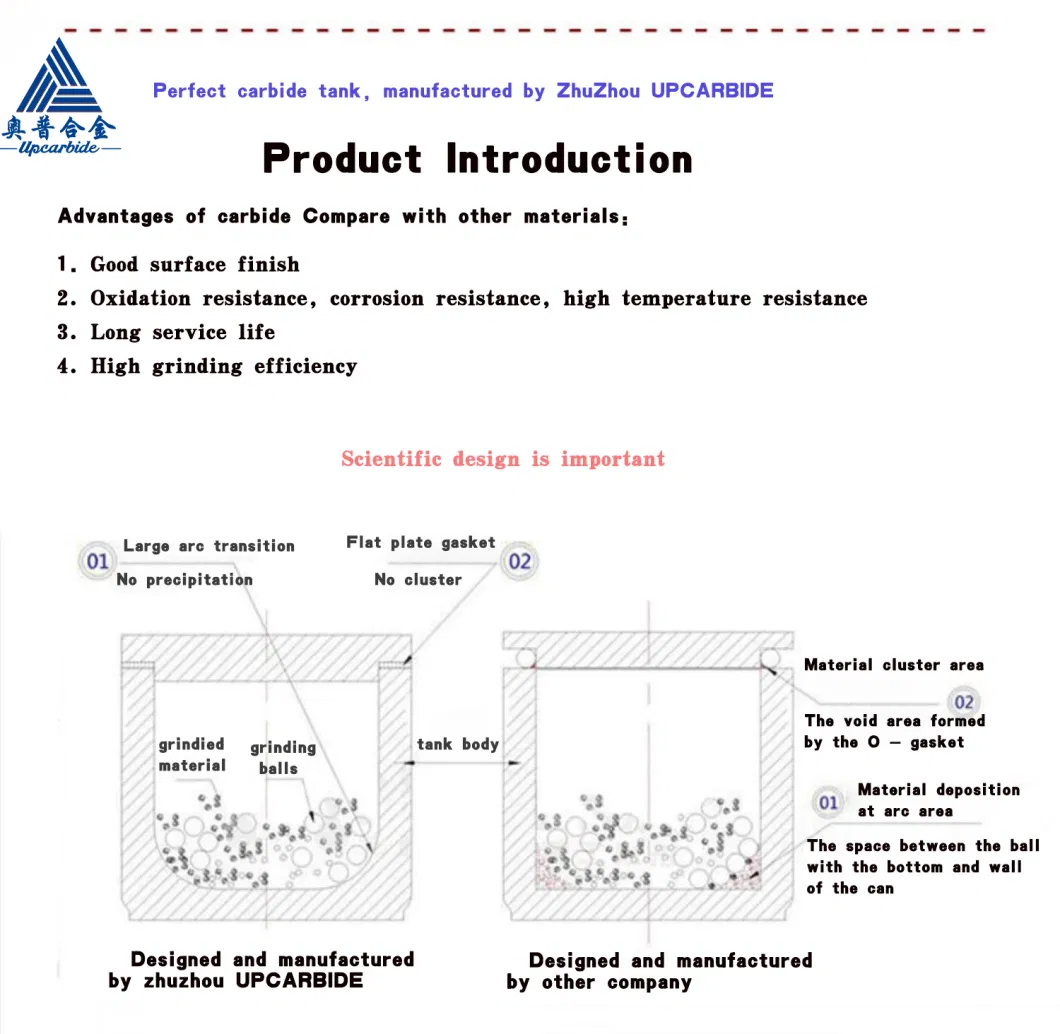

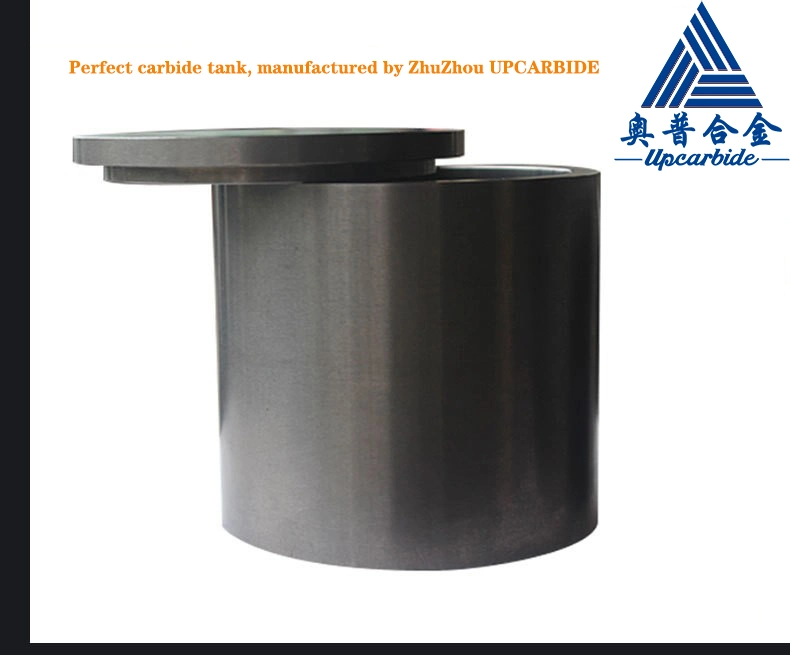

Customize sizes according drawng polished Tungsten Alloy Grinding Bowl

Products description

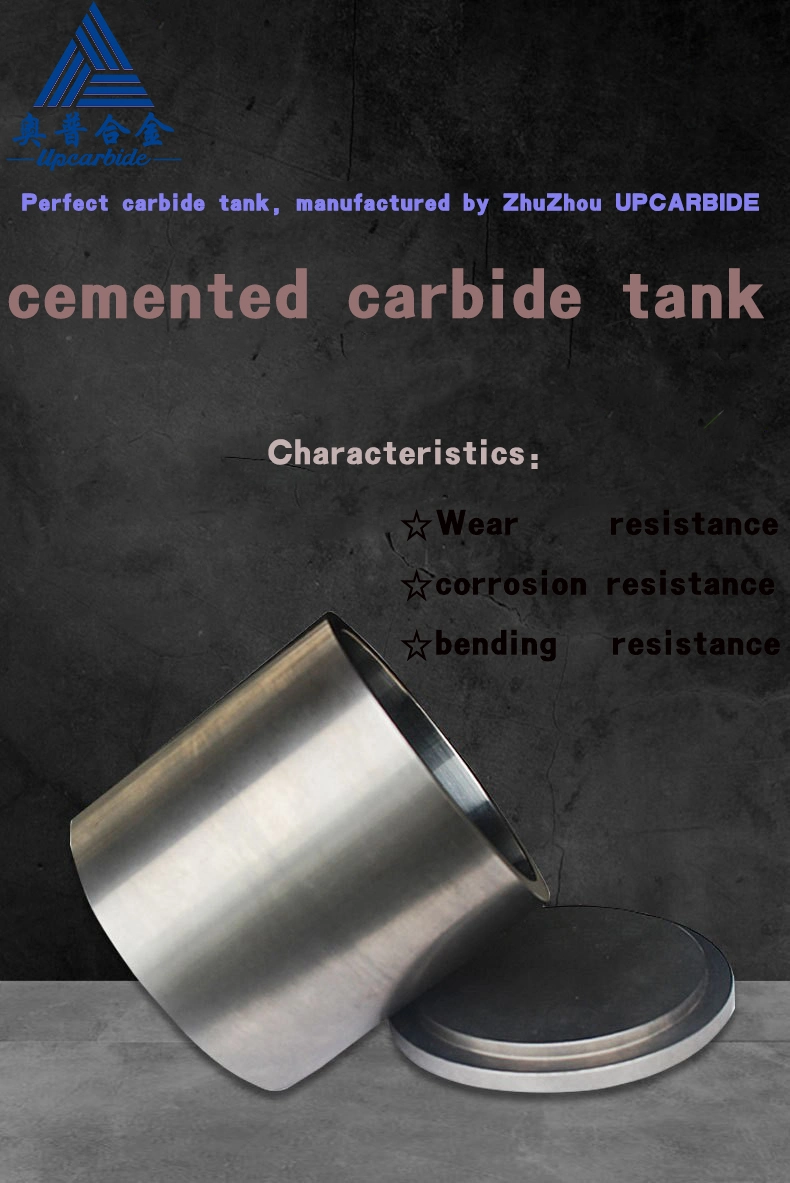

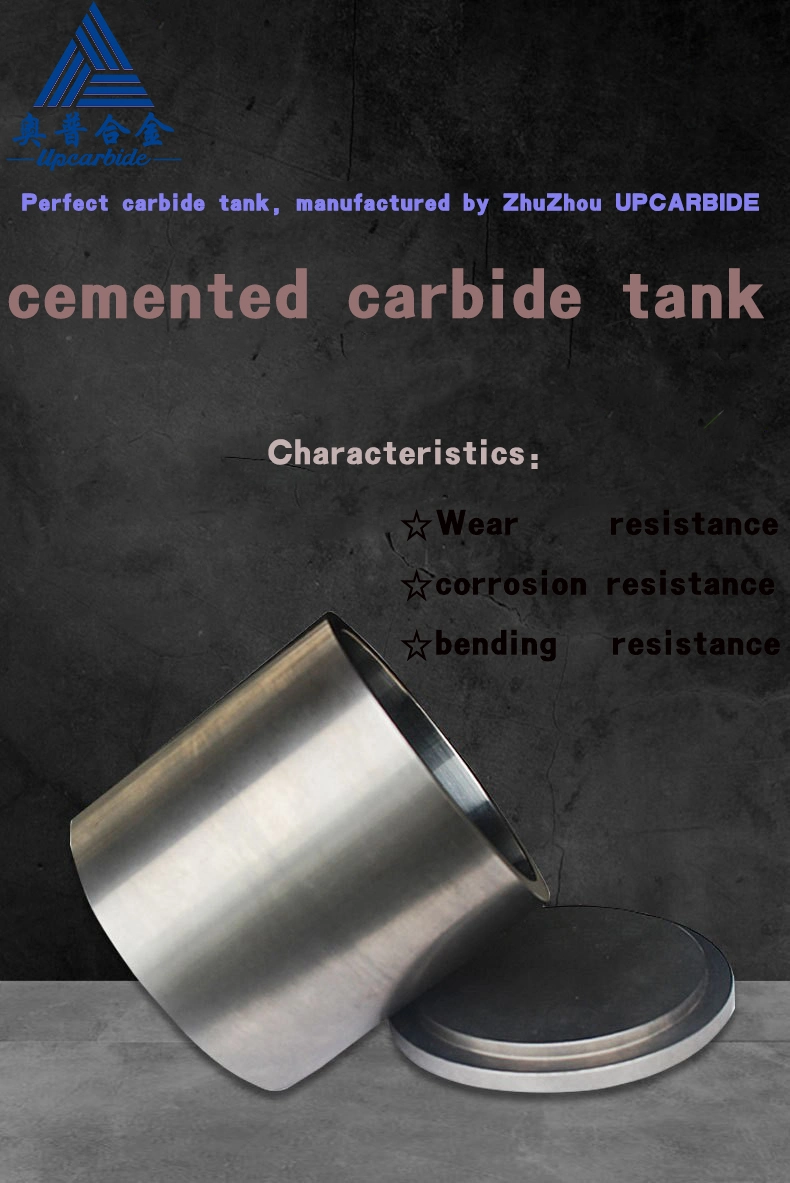

cemented carbide mill jar

Specifications

1. Grade: YG8 , 8% Co

2. YG8,YG6,YG3,YG10,YG15,YT14,YT5,YT05,YT15,YG20,YG25,YL10.2,YS2T,YG6X etc all kinds of grades for your choose.

3. Can product customize drawing,sizes and shape.

Products description

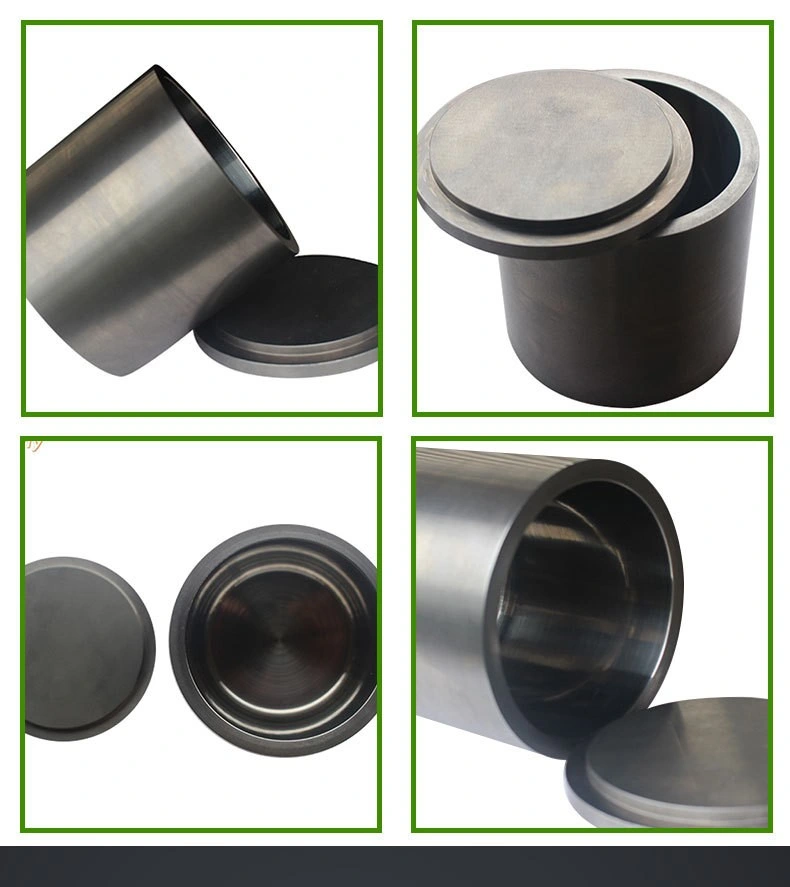

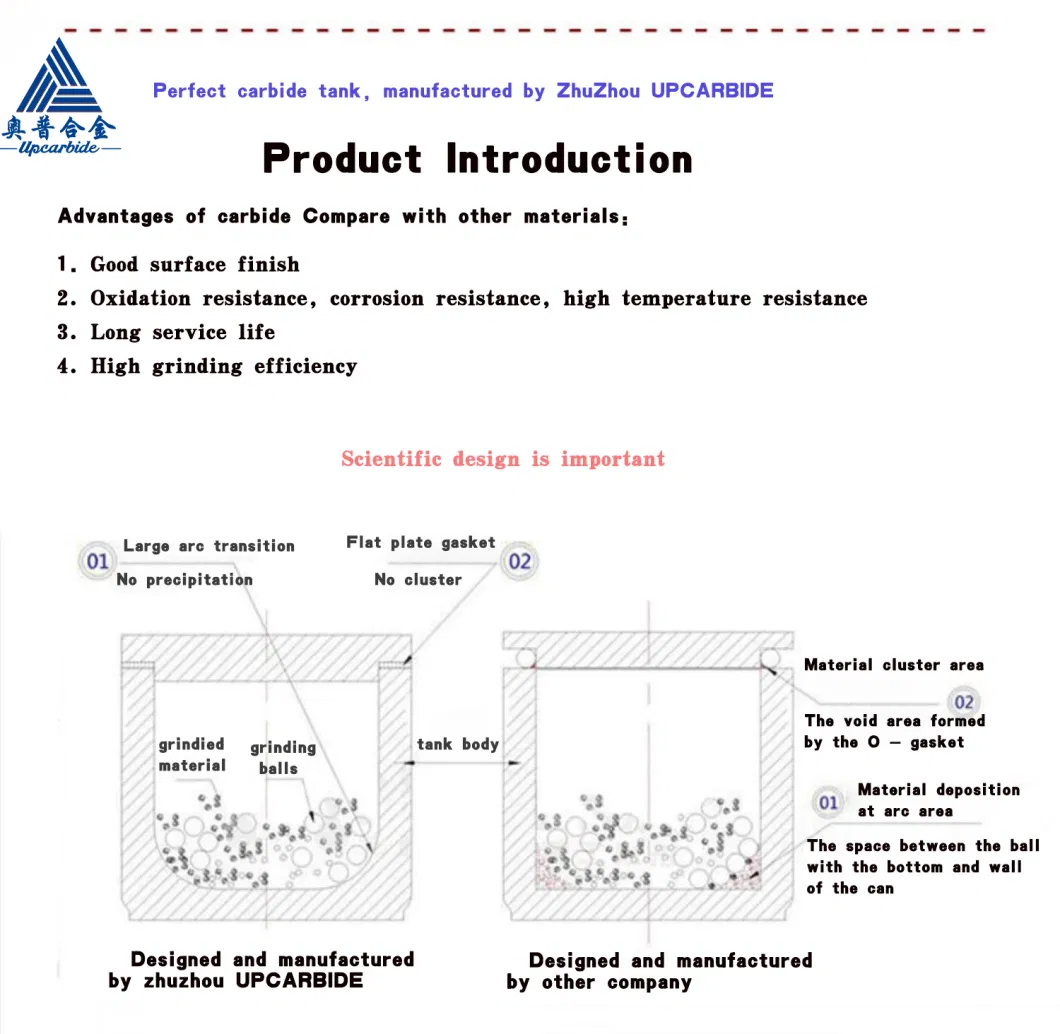

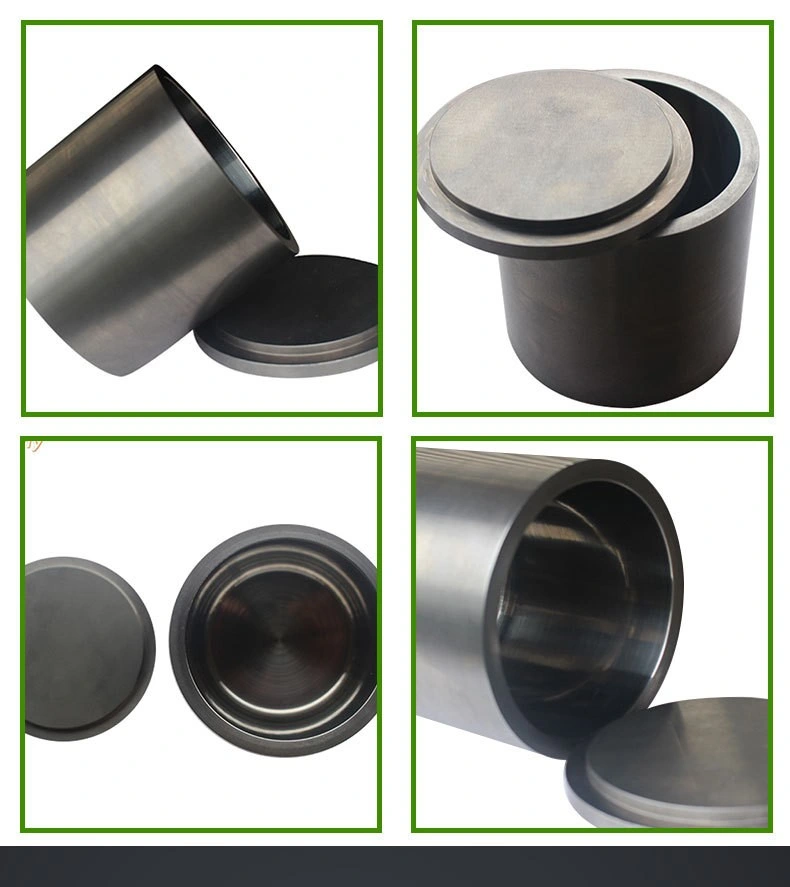

1. Jar Volume: 25ML~1000ML (25ML/30ML/35ML/40ML/50ML/60ML/70ML/80ML/90ML/100ML etc)

2. Match tungsten carbide or ceramics grinding ball

3. Max Loading Capacity:2/3 capacity of the grinding jar

4. Density: 14.0g/cm³ ,14.5g/cm³, 14.8g/cm³

5. Main Chemical Compositions: WC (94%,92%,85%),Cobalt (6%,8%, 15%)

6. Surface Treatment: blank or finish

7. Abrasion Resistance: very good

8. Attachment:lid and rubber sealing gasket

9. Grinding Balls: mixed tungsten carbide ball(should be ordered separately)

10.Hardness: 85.5HRA , 89.5HRA ,90.5HRA, 91.8HRA OR 92.1HRA

11. Also product the goods according the Customize drawing

2. Match tungsten carbide or ceramics grinding ball

3. Max Loading Capacity:2/3 capacity of the grinding jar

4. Density: 14.0g/cm³ ,14.5g/cm³, 14.8g/cm³

5. Main Chemical Compositions: WC (94%,92%,85%),Cobalt (6%,8%, 15%)

6. Surface Treatment: blank or finish

7. Abrasion Resistance: very good

8. Attachment:lid and rubber sealing gasket

9. Grinding Balls: mixed tungsten carbide ball(should be ordered separately)

10.Hardness: 85.5HRA , 89.5HRA ,90.5HRA, 91.8HRA OR 92.1HRA

11. Also product the goods according the Customize drawing

cemented carbide mill jar

Specifications

1. Grade: YG8 , 8% Co

2. YG8,YG6,YG3,YG10,YG15,YT14,YT5,YT05,YT15,YG20,YG25,YL10.2,YS2T,YG6X etc all kinds of grades for your choose.

3. Can product customize drawing,sizes and shape.

Products Show

Grades choosing

Common grades for all kinds metal

| Grade | Density g/cm3 | Hardnes HRA | T.R.S Mpa | Performance&application recommended |

| YG6A | 14.85 | 92.5 | 2000 | Fine grain alloy,good wear resistance.it is suitable for manufacturing forming cutter,wear-resistant parts etc. |

| YG8 | 14.7 | 89.8 | 2800 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG11 | 14.4 | 88.5 | 2900 | High bending strength,wear resistance lower than YG6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YG15 | 14.0 | 87.0 | 3000 | Suitable for manufacturing punching dies, wear-resistant parts. |

| YG20 | 13.5 | 85.5 | 2800 | High bending strength,suitable for manufacturing progressive dies and other punching dies. |

| YG25 | 13.1 | 81.5 | 2950 | High bending strength,wear resistance lower than YM6A, suitable for manufacturing cutter ,wear-resistant parts etc. |

| YS2T | 14.25 | 92.0 | 2500 | Fine grain alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. it is suitable for machining refractory alloys,stainless steel, high manganese steel, etc. |

Other grades and sizes can be offered as per customers' requirements

Packing details

Shipping ways

Production process