Basic Info.

Model NO.

Cold Forming Die

Hardness

89.5hra

Density

14.8g/cm3

T.R.S

2600MPa

Surface

Only Sintered

Width Allowances

-0.15~+0.15

Thickness Allowances

-0.15~+0.15

Length Allowance

-0.2~+0.2

Transport Package

25kg. Carton

Specification

YG8/K20

Trademark

ZZUP

Origin

Zhuzhou, Hunan, China

HS Code

820900100

Production Capacity

10000000PCS/Month

Product Description

Yg8/K20 tungsten carbide die

Specifications

1. YG8,YG6,YG10,YG15,YG20,YG25,YL10.2,YS2T,YG6X etc all kinds of grades for your choose.

2. Supply sintered or ground and polished surface.

3. Can HIP sintered,higher harndess, strength and density.

4. We have more than 1000 sets molds for different sizes.

5. Supply customized package.

6. Can product customize sizes and shape.

Specifications

1. YG8,YG6,YG10,YG15,YG20,YG25,YL10.2,YS2T,YG6X etc all kinds of grades for your choose.

2. Supply sintered or ground and polished surface.

3. Can HIP sintered,higher harndess, strength and density.

4. We have more than 1000 sets molds for different sizes.

5. Supply customized package.

6. Can product customize sizes and shape.

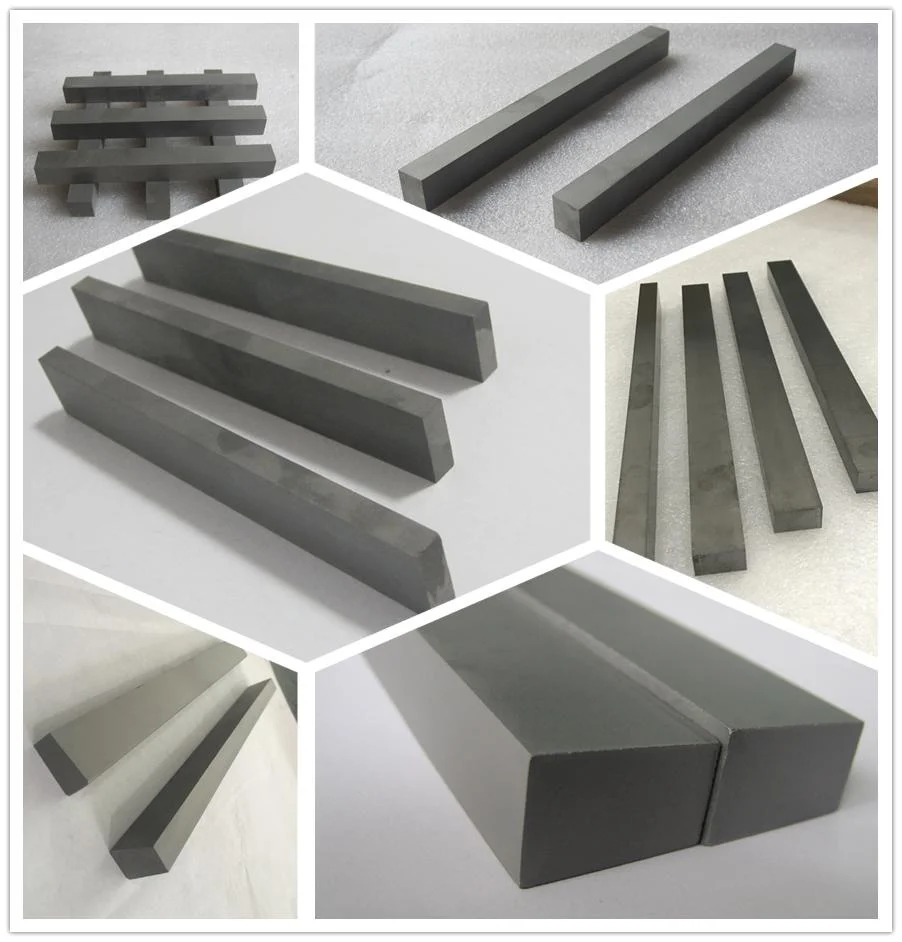

Products Show

Grades choosing

| Grade | Density g/cm3 | Hardnes HRA | T.R.S Mpa | Performance&application recommended |

| YG6 | 14.90 | 90.5 | 2400 | Good wear resistance,suitable for machining hard, rawwood,aluminum section bar,brass rod and cast iron. |

| YG6X | 14.85 | 92.5 | 2000 | Wear resistance higher than YG6,suitable for machining hard,rawwood,aluminum section bar,brass rod and cast iron. |

| YG8 | 14.7 | 89.8 | 2800 | High wear and impact resistance,suitable for machining dry wood,soft wood and non-ferrous metal section bar |

| YS2T | 14.25 | 92.0 | 2400 | Fine grain alloy,with high wear resistance,bending strength,bonding resistance and thermal strength.lt is suitable formachining refractory alloys,stainless steel,high manganesesteel,etc. |

| YL10.2 | 14.45 | 91.8 | 3000 | Wear resistance and strength comparatively higher,suitable for machining cast iron,non-ferrous metal and non-metallid materials |

Other grades and sizes can be offered as per customers' requirements

Sizes choosing

| W(mm) | T(mm) | L(mm) | | W(mm) | T(mm) | L(mm) |

| 3~10 | 1.2~10 | 10~800 | | 50~60 | 1.2~10 | 10~800 |

| 10~20 | 1.2~10 | 10~800 | | 60~70 | 1.2~10 | 10~800 |

| 20~30 | 1.2~10 | 10~800 | | 70~80 | 1.2~10 | 10~800 |

| 40~50 | 1.2~10 | 10~800 | | 80~100 | 1.2~10 | 10~800 |

| 17 | 1.2~10 | 10~800 | | | | |

Packing details

Shipping ways

Production process

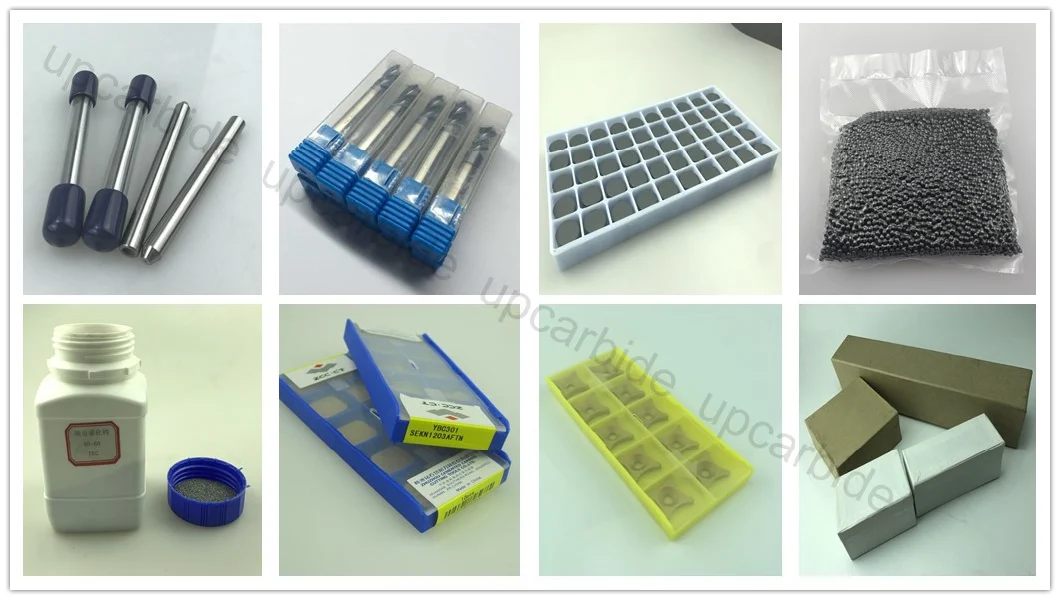

similar products.