- Overview

- Hot Sale Products

- Product Description

- Product Parameters

- Company Profile

- Our Advantages

- After Sales Service

Basic Info.

Model NO.

TCMT 110208

Material

Cemented Carbide

Type

Lathe Turning Tool

Coating Element

CVD

Color

Yellow or Black

Hardness

Hra92

Working Material

Cutting Steel

Machining Catagory

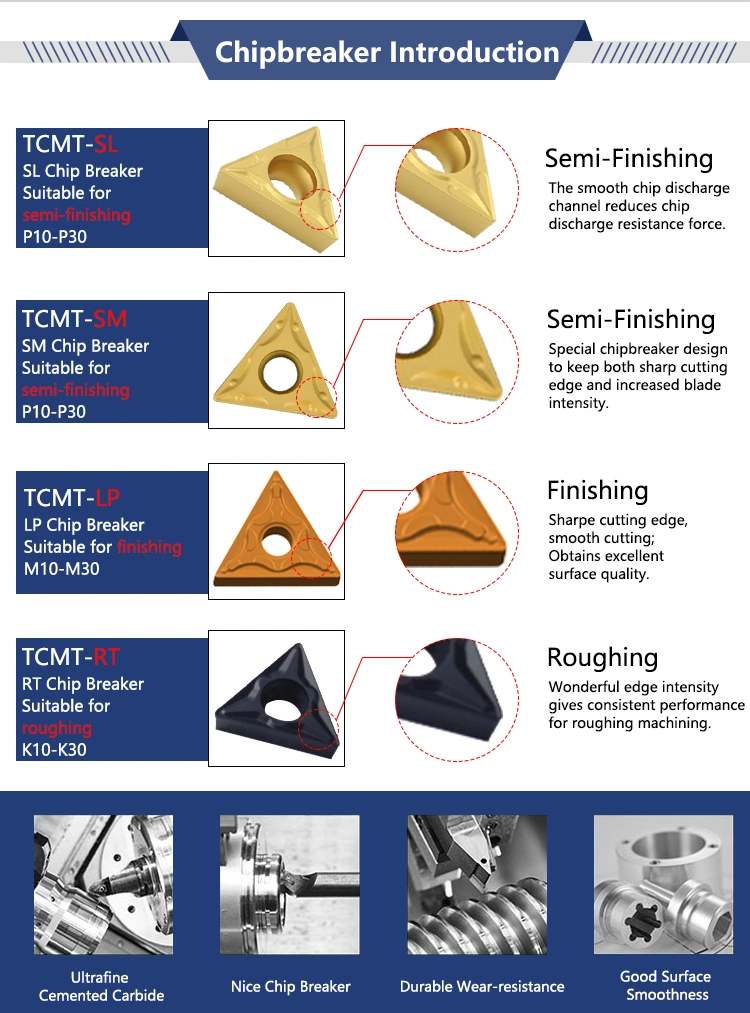

Finishing, Semi-Finishing, Roughing

Comparision Grade

Ue6020

Tool Life

Durability and Stability

Delivery

DHL/EMS/FedEx/TNT/UPS

Package

10PCS in One Box

Stock Status

in Stock

Customization

OEM/ODM

After-Sale Service

Yes

Transport Package

Cartons

Specification

10*10*10mm

Trademark

SENO

Origin

China

HS Code

8208101100

Production Capacity

500000/Month

Packaging & Delivery

Package Size

10.00cm * 5.00cm * 2.00cm

Package Gross Weight

0.020kg

Product Description

High Quality CNC Indexable Carbide Inserts Cutter Tools For Steel TCMT 110208

| Model | TCMT 110204/08 | TCMT 16T304/08 | |

| Grade | SP8025/SP8125/SM8020/SK8010 | ||

| Workpiece | steel/hardened steel/ stainless steel/cast iron | ||

| Coating | CVD/PVD coating | ||

| MOQ Quantity | 10pcs | ||

| Package | 10pcs in one box | ||

| Service | OEM/ODM | ||

| Grade for turning inserts | ||||

| SENO GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

| SP8025 | CVD (MT-TiCN+Al2O3+TiN) | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

| SP8125 | CVD (Multi-TiCN+Al2O3) | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

| SM8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel |

| SK8010 | CVD (thick TiCN+ textured Al2O3) | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. |

1) Please contact us if you meet any product quality problem;

2) Please contact us if you meet any custom clearance problem;

3) Please contact us if you get wrong products or miss something;