Basic Info.

Model NO.

customized and standard

Shaping Mode

Die Casting

Hole Type

Round Mould

Cavity

Single-cavity

Surface Treatment

Blank

Certification

ISO

Warranty

1 Year

Customized

Customized

Free Sample

Available

Delivery

Very Fast

Mould

2000set More

Grain Size

Ultra Fine,Extra Fine

Purity

>99.5%

Standard

JIS, GB, DIN, BS, ASTM, AISI

Tolerance

+/-0.001mm

Transport Package

Small Box Inside a Carton

Specification

tungsten and coblat powder

Trademark

Evergreen or OEM

Origin

China

HS Code

8209009000

Production Capacity

3 Tons/ Month

Packaging & Delivery

Package Size

28.00cm * 29.00cm * 15.00cm

Package Gross Weight

1.000kg

Product Description

Application

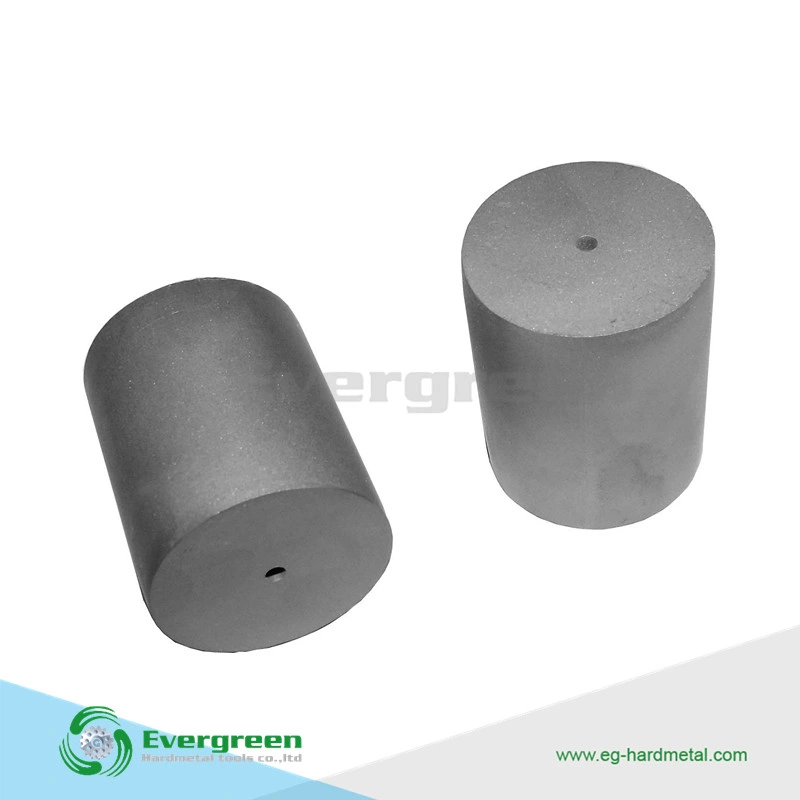

Wire drawing molds are widely used, such as electronic devices, radar, television, instruments and aerospace and other high-precision wire, as well as commonly used tungsten wire, molybdenum wire, stainless steel wire. Wire cable wire and all kinds of alloy wire are drawn by diamond drawing die. The diamond drawing die has extremely strong wear resistance and long service life because of the use of natural diamond as raw material.

Grade for Tungsten Carbide Punching Dies

Some typical types of tungsten carbide puching dies

Heading die blanks for making standard bolts

Die blanks for reducing diameter of nuts

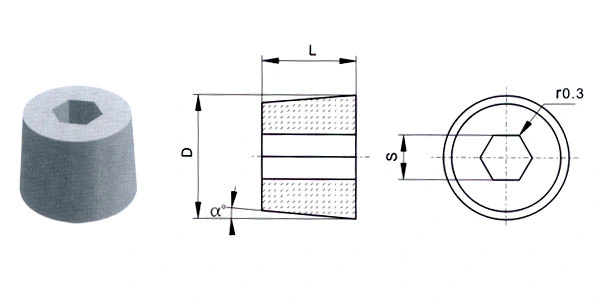

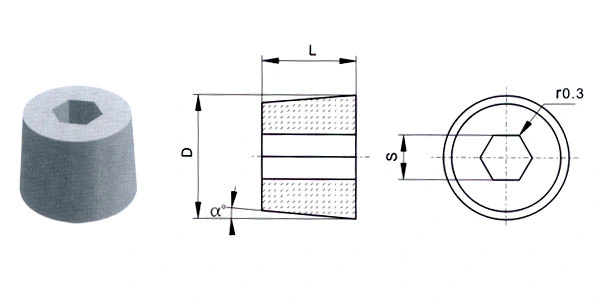

Heading die blanks for making hexagonal nuts

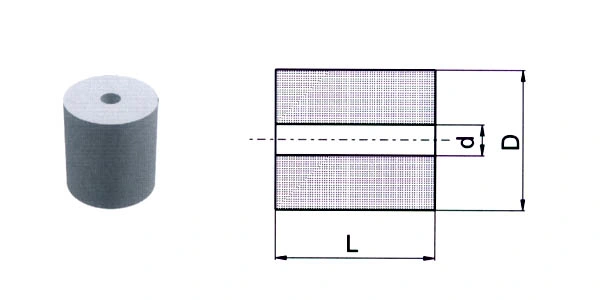

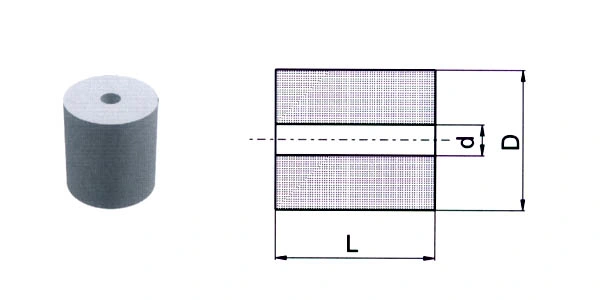

Some standard types of tungsten carbide wire drawing dies

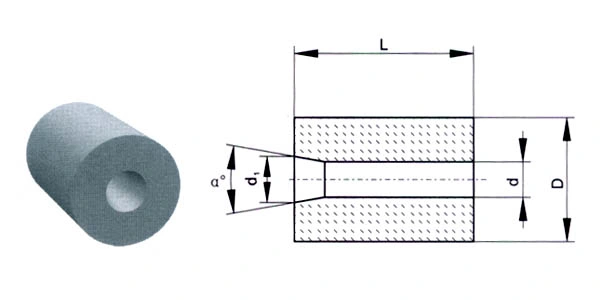

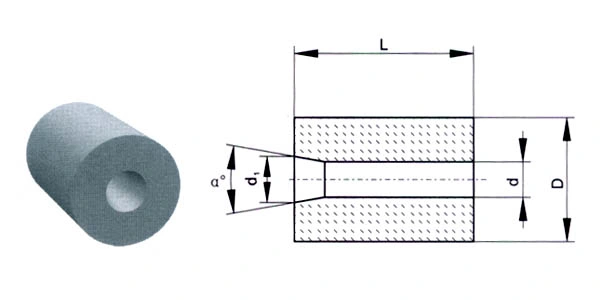

Type S11-Carbide drawing die nibs with large reducing angles

for drawing ferrous metal wires

Type W

Advantage

1. Superior strength, toughness and high wear resistance with long working life .

2. 100% virgin tungsten carbide materials

3: ISO 9001 quality control system

4: Professional suggestion on products

5: Is very wide, mainly for drawing bar, wire, wire, pipes and other linear objects difficult to process for steel, copper, tungsten, molybdenum and other metals and alloys drawing processing;

Contact us;

Emily

+86 19973339509

Zhuzhou Evergreen hardmetal Tools Co., Ltd.

Wire drawing molds are widely used, such as electronic devices, radar, television, instruments and aerospace and other high-precision wire, as well as commonly used tungsten wire, molybdenum wire, stainless steel wire. Wire cable wire and all kinds of alloy wire are drawn by diamond drawing die. The diamond drawing die has extremely strong wear resistance and long service life because of the use of natural diamond as raw material.

Grade for Tungsten Carbide Punching Dies

| Grades | Density g/cm3 | T.R.S MPa | Hardness HRA | Performance & application recommended |

| YG11 | 14.4 | 2600 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. |

| YG15 | 14.0 | 2800 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching,stamping,forging tools under large stress. |

| YG20 | 13.5 | 3200 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. |

| YG16C | 13.9 | 2900 | 85.5 | Impact resistance forging dies. |

| YG18C | 13.7 | 3100 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. |

| YG20C | 13.5 | 3300 | 83.5 | Dies for wear resistant or impact resistant application. |

| YG22C | 13.3 | 3500 | 83.0 | Nut forming dies and high impact resistance forging dies. |

| YG25C | 13.1 | 3600 | 82.5 | Stainless bolt header dies and rollers. |

Some typical types of tungsten carbide puching dies

Heading die blanks for making standard bolts

Die blanks for reducing diameter of nuts

Heading die blanks for making hexagonal nuts

Some standard types of tungsten carbide wire drawing dies

Type S11-Carbide drawing die nibs with large reducing angles

for drawing ferrous metal wires

| Type | D | H | Range of d | h | α° |

| S11- | 8 | 6 | 0.3-1.0 | 0.3-0.6 | 14° |

| 10 | 8 | 0.7 | 0.6 | 14° | |

| 13 | 10 | 0.4-2.8 | 0.3-1.6 | 16° | |

| 15 | 13 | 0.5-3.0 | 0.3-1.4 | 16° | |

| 16 | 14 | 0.4-3.8 | 0.3-1.8 | 16° | |

| 20 | 17 | 1.2-4.7 | 2.0-2.6 | 18° | |

| 21 | 17 | 1.8-5.7 | 1.2-3.0 | 18° | |

| 22 | 18 | 1.7-6.4 | 1.2-3.0 | 18° |

Type W

Advantage

1. Superior strength, toughness and high wear resistance with long working life .

2. 100% virgin tungsten carbide materials

3: ISO 9001 quality control system

4: Professional suggestion on products

5: Is very wide, mainly for drawing bar, wire, wire, pipes and other linear objects difficult to process for steel, copper, tungsten, molybdenum and other metals and alloys drawing processing;

Contact us;

Emily

+86 19973339509

Zhuzhou Evergreen hardmetal Tools Co., Ltd.