- Overview

- Introduction

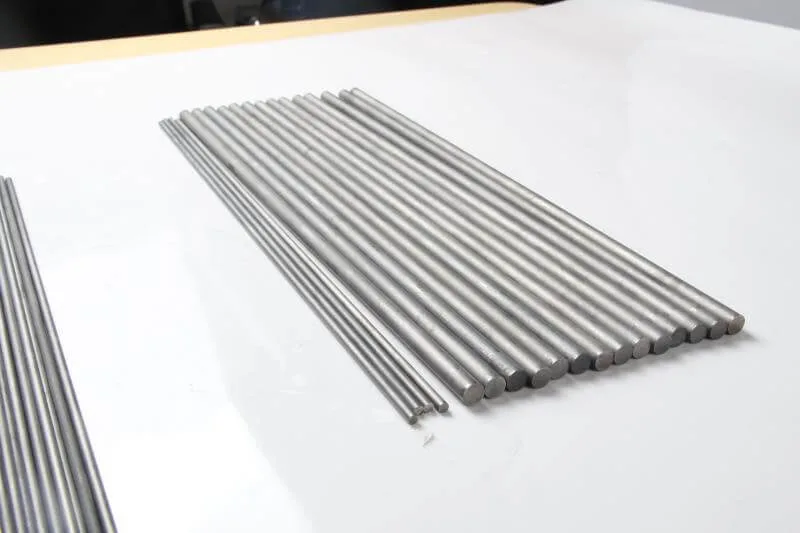

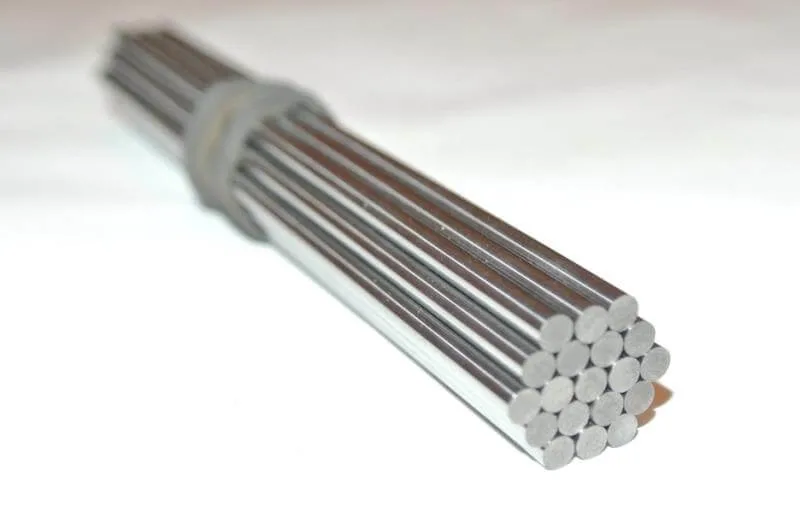

- Product Details

- Packaging

- Reviews From Customers

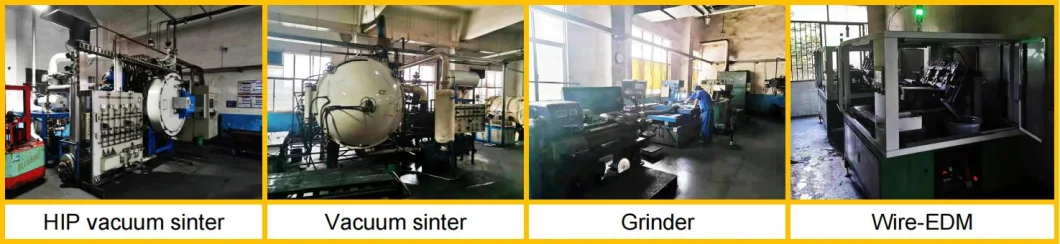

- Company Profile

- Company Advantage

- FAQ

Basic Info.

Product Description

Miller Carbide aims to supply the first -class level tungsten carbide rods for cutting tool industry as well as the machining industry. Miller Carbide stands for more than 15 years of expertise in tungsten carbide. Patented extrusion technology, innovative grade developments, cylindrical grinding services along with our well trained employee enable us to offer you substantial price-performance advantages for high performance carbides.

We Offer Tungsten Carbide Rod

- As sintered-solid carbide rods, rods for PCB tools, rods with central duct, rods with two straight coolant ducts, rods with two coolant ducts with helix 30°& 40°

- Ground -h5 /h6 / h7

- Standard blanks, chamfered one end

- Non standard blanks cut to order

Solid carbide rods blanks Ground rods for cutting tools Carbide rods with two duct hole

Tolerance Grade of Ground Rod

| Diameter | H5 (Tolerance Grade) | H6 (Tolerance Grade) | H7 (Tolerance Grade) |

| 0-3.0 mm 0-0.11811 in | 0.004 mm 0.00015 in | 0.006 mm 0.00024 in | 0.010 mm 0.00039 in |

| 3.001-6.0 mm 0.11812-0.23622 in | 0.005 mm 0.00020 in | 0.008 mm 0.00031 in | 0.012 mm 0.00047 in |

| 6.001-10.0 mm 0.23623-0.70866 in | 0.006 mm 0.00024 in | 0.009 mm 0.00035 in | 0.015 mm 0.00059 in |

| 10.001-18.0 mm 0.39371-0.70866 in | 0.008 mm 0.00031 in | 0.011 mm 0.00043 in | 0.18 mm 0.00071 in |

| 18.001-30.0 mm 0.90867-1.18110 in | 0.009 mm 0.00035 in | 0.013 mm 0.00051 in | 0.021 mm 0.00083 in |

| 30.001-50.0 mm 1.8111-1.96850 in | 0.011 mm 0.00043 in | 0.016 mm 0.00063 in | 0.025 mm 0.0098 in |

Product Advantage

Tungsten Carbide Grades for Rods

| MILLER CARBIDE Grade | Binder Co (vol%) | Grain Size (μm) | Density (g/cm³) | Hardness (HRA) | TRS (Mpa) |

| MC6U | 6±0.3 | 0.4-0.5 | 14.85-15.0 | 93.5-94 | 3700 |

| MC6X | 6±0.3 | 0.8-1.0 | 14.82-14.90 | 90.5-91.5 | >1700 |

| MC8 | 8 | 1.2-1.6 | 14.7-14.78 | 89.5-90.5 | >2300 |

| MC8U | 8 | 0.4-0.5 | 14.65 | 93.6 | 3700 |

| MC10S | 10 | 0.6 | 14.40 | 92.2 | 4200 |

| MC10F | 10 | 0.8 | 14.40 | 91.5 | 3600 |

| MC12U | 12 | 0.4-0.5 | 14.25 | 92.6 | 3700 |

Tungsten Carbide Applications

| Grade/Application | MC6U | MC6X | MC8 | MC8U | MC10S | MC10F | MC12U |

| Carbon steel | √ | √ | |||||

| Tempered steel | √ | ||||||

| Hardened steel | √ | √ | √ | ||||

| Stainless steel | √ | √ | √ | √ | |||

| Austenitic stainless steel | √ | ||||||

| Greycast iron | √ | ||||||

| Heat resistant alloy | √ | √ | √ | √ | |||

| Titanium alloy | √ | √ | √ | ||||

| Nickel alloy(Inconel) | √ | √ | √ | ||||

| Aluminium alloys | √ | √ | |||||

| Composite materials | √ | √ | √ | √ | √ | ||

| CFRP | √ | √ | √ | √ | √ | ||

| Graphite | √ | √ | √ | √ | |||

| Resin | √ | ||||||

| Wood | √ | √ |

Miller Carbide is an experienced manufacturer of tungsten carbide customized parts started from 2008. Our products cover carbide grinding jars & mortars, carbide grinding balls, carbide pegs, carbide static & dynamic rings, bead mill disks, carbide stirring rods, carbide static & dynamic jaws, carbide crusher plates, carbide grinding discs, carbide rotors, carbide roll rings, carbide guide rolls, carbide burrs, carbide sleeves & bushings, and other customized wear-resistant components for valve and pumps ect. With years of tungsten carbide engineering and manufacturing experience, we can concentrate our skills to the development of customized products for a wide spread of wear applications in milling & crushing industry.

Unlike other suppliers, Miller operates with three disciplines: Engineering, manufacturing and after sale service support. This means we are able to improve the efficiency of your machine and tools with customized products and direct access to the manufacturer. Miller Carbide works closely with its customers to ensure their requirements are designed efficiently and suitable for application. We can design the components needed from drawings or delivered samples.

We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. We are sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

We Offer You These

| Direct Sales Integrating R&D, production sales and technology | Mold customization Rich molds OEM customization accepted | Adequate equipment grinding/pressing sintering/deep processing | Technical strength 15 years of experience in technical team, research & innovation |

1. How long is your delivery time?

We can arrange the shipment within 3-5 working days upon receipt of your payment for any sintered blanks stocked items. As for the mass production order or the customized products, we will need 10-30 days production leadtime and indicate the delivery time on the Proforma lnvoice.