Basic Info.

Product Description

2. Carbide wear parts for oil and gas industry, wellhead assembly (eg. Christmas tree, multistage choke manifold)

3. Customized tungsten carbide choke valve stem and seat according to drawings.

Hardened alloy Steel Stems and Seats are widely used in Adjustable Needle & Positive Choke assemblies. Stainless Steel or stainless steel with Tungsten Carbide tips for Abrasive and or Sours Gas Service are available on request. Positive Choke assemblies are furnished less flow bean and may be converted to Adjustable Choke assemblies by replacing the blanking cap assembly and flow bean with the appropriate adjustable bonnet assembly and seat.

Customized various kinds Valve Plugs and Seats

Company Introduction:

Zonco has been specialized in customizing various kinds of non-standard tungsten carbide wear resistant components for more than 10 years.Our products and technologies have been widely applied in the fields of oil & gas (such as downhole tools(dill bits, chrismas tree, RSS, PDM), wellhead equipment, subsurface valves, MWD/LWD Tools) and chemical engineering, subsea, valve, pump, mechanical equipment. Mainly used in harsh operating conditions include severe abrasion, erosion, corrosion, high temperature, high pressure and strong impact. we are able to manufacturing all kinds of wear resistance valve parts based on customer's drawing and material requirement, support hardfacing process based on customer's technique requirement. since most of our products are customized and not suitable to show for other customer, welcome to contact us for OEM service.

Our main products Types:

1. Carbide nozzles for Oil Drill Bits, nozzle sleeve, bushing.

2. Carbide parts for MWD/LWD tools, such as rotor,stator,liner,sleeve, plate,retainer,shroud etc.

3. Carbide Parts for downhole tools,such as torque impactor, centralizer, fracturing nozzle, stationary valve Assy and OSC valve Assy in Hydraulic oscillator etc.

4. Carbide Radial Bearing, such as TC bearing, PDC bearing.

5. Valve Trim, such as valve plug, stems, seats, cage, choke bean,choke stem.

6. Steel bonded tungsten carbide Assy and Surface Technology on Steels (PTA,HVOF, Boriding).

7. Other customized carbide parts based on client's drawings etc.

Customizable Products Display:

Zonco Common Tungsten Carbide Grades, Ghysical Mechanical Properties:

| Grade | WC% | Co% | Grain size (μm) | |||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | ||||

| YG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 0.8-1.2 |

| YG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 |

| YG08 | 92 | 8 | 14.6-14.9 | 2700 | 89 | 1.2-1.6 |

| YG10.2 | 90 | 10 | 14.3-14.6 | 3800 | 91.7 | 0.7 |

| YG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 |

| YG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 |

| YG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 |

| YG20 | 80 | 20 | 13.4-13.8 | 3100 | 85 | 1.2-1.6 |

2. Nickel Binder Grades

| Grade | WC% | Ni% | Physical and mechanical properties | Grain size (μm) | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | ||||

| YN6 | 94 | 6 | 14.5-14.9 | 2000 | 90 | 1.2-1.6 |

| YN9 | 91 | 9 | 14.3-14.6 | 2300 | 89 | 1.2-1.6 |

| YN11 | 89 | 11 | 14.0-14.3 | 2600 | 88 | 1.2-1.6 |

Our material engineers have developed more than 15 material grades. If the listed grades above are not meet your requirement,

we are able to recommend or develop new grade by customers' requirements.

Why choose us:

1. Experienced with new producing technology and facilities of surface treatment to improve hardness,corrosion resistance

erosion resistance with lower cost.

2. Customized service is available according to client's drawings or requirements.

3. Production lines entirely accord with International Quality Certification of ISO9001.

4. Factory direct sale with 20-30% price off.

5. More flexible production management with faster lead time.

What is surface treatment and its advantages?

Surface treatment is an additional process apply cemented carbide to the surface of a material for the purpose of adding functions such as erosion resistance,corrosion resistance and wear resistance or improving the hardness,by which lower the cost compared to the cost of using entire cemented alloy,and remain the alloy good performance upon the material.

Surface treatments can be broadly classified into removal processes, such as scraping or melting the surface, and additive processes, such as painting,coating which add cemented carbide to the surface.there are four technical surface treatments we have in image below as additive processes to highly improve property of wear resistance and erosion resistance.

International Quality Certification ISO9001 of Cemented Tungsten Carbide

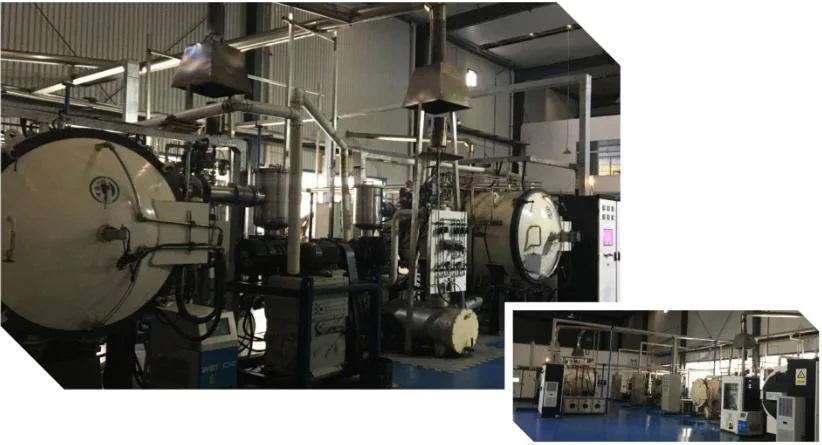

Production Plant/Factory

Address: Building A3, Minor Enterprises Promotion Park, Huanhe Road(N), Tianyuan District, Zhuzhou, Hunan, China

Welcom to visit our factory in Zhuzhou,China! and please feel free to contact me if you're looking for high quality supplier of cemented tungsten carbide parts and materials.

The department of raw virgin preparation and compression

The department of HIP sintering

The factory's interior

Technological process of cemented carbide

Corporation Main Gate

Conference/Meeting room