Basic Info.

Model NO.

LGJ170628012

Size

Any Size Accepted Customized

Grade

Yg6,Yg8,Yg8c,Yg11,Yg11c,Yg15c

Surface

Polished or Unground

Delivery Time

15days

Applications

Mining Tools

Tolerance

+/-0.05

Product Name

Tungsten Carbide

Quality

100% Virgin Materials

Shipping

DHL,FedEx,TNT,UPS,EMS

MOQ

10 PCS

Transport Package

Carton

Specification

Customized

Trademark

Old Craftsman

Origin

Hunan

HS Code

82090090

Production Capacity

7000kg/Month

Product Description

carbide drill bits

1.100% raw material to produce tungsten carbide products.

2. Hip sintered, high hardness, high wear resistance

3. Various sizes and full types available

4. Reasonable price,Fast delivery time

5. OEM Customized(small order accepted,professional technical support)

6.ISO 9001 Certification

More details of specific type, please inform us

Grade information of carbide drill bits:

Size of tungsten carbide Chisel Bit Teeth:

Cutomized shape and size are welcome to make.

Application of carbide drill bits:

It is used as wear insert of drill bits for Mining hard/soft rock .

Company Information

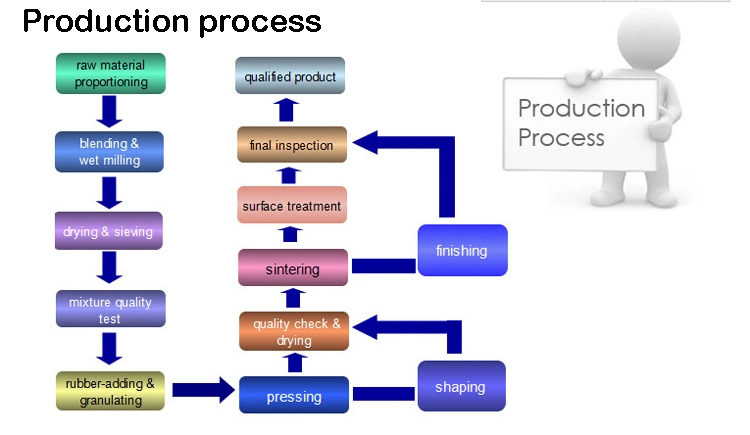

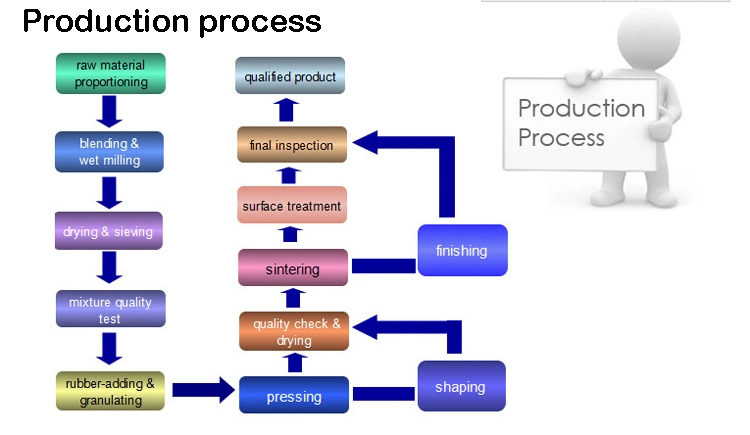

Production process

Packing and Delivery

Payment terms

RAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<1000USD, 100% in advance. Payment>1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us!

1.100% raw material to produce tungsten carbide products.

2. Hip sintered, high hardness, high wear resistance

3. Various sizes and full types available

4. Reasonable price,Fast delivery time

5. OEM Customized(small order accepted,professional technical support)

6.ISO 9001 Certification

More details of specific type, please inform us

Grade information of carbide drill bits:

| Grade | Density (g/cm³) | TRS (MPa) | Hardness (HRA) | Performance & application recommended |

| YG4C | 15.10 | 1800 | 90.0 | Mainly used as small buttons for percussion bits to cut soft and medium hard formations. |

| YG6 | 14.95 | 1900 | 90.5 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

| YG8 | 14.80 | 2200 | 89.5 | For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

| YK05 | 14.95 | 2500 | 90.5 | Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

| YG8C | 14.80 | 2400 | 88.5 | |

| YK15 | 14.60 | 2450 | 87.6 | Suitable to strips, conical buttons for rotary percussion-resistant, geological prospection buttons, cut soft and medium hard formations. |

| YK20 | 14.40 | 2500 | 86.8 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

| YK25 | 14.40 | 2550 | 87.2 | Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations. |

| YG11C | 14.40 | 2700 | 86.5 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

| YG13C | 14.2 | 2850 | 86.0 | Primarily for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and very hard formations. |

| YG15C | 14.0 | 3000 | 85.5 | For oil cone drill bits, for medium soft and medium-hard rocks. |

| YG16C | 13.95 | 2900 | 85.0 | Suitable for PDC insert and roller bits |

| Type | Dimensions(mm) | ||||||||

| L | H | S | R | r | R1 | ||||

| Dim. | Tol. | Dim. | Tol. | Dim. | Tol. | ||||

| K026D | 26 | ±0.6 | 12 | ±0.5 | 8 | 0 - 0.6 | 50 | 13 | 0.5 - 1.0 |

| K026B | 26 | 15 | 8 | 50 | 13 | ||||

| K034E | 34 | 12 | 8 | 80 | 17 | ||||

| K034D | 34 | 13 | 8 | 80 | 17 | ||||

| K038H | 38 | ±0.7 | 12 | 10 | 180 | 19 | |||

| K040B | 40 | 15 | 10 | 180 | 20 | ||||

| … | … | … | … | … | … | … | … | … | |

Cutomized shape and size are welcome to make.

Application of carbide drill bits:

It is used as wear insert of drill bits for Mining hard/soft rock .

Company Information

Production process

Packing and Delivery

Payment terms

RAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<1000USD, 100% in advance. Payment>1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us!