- Overview

- Product Description

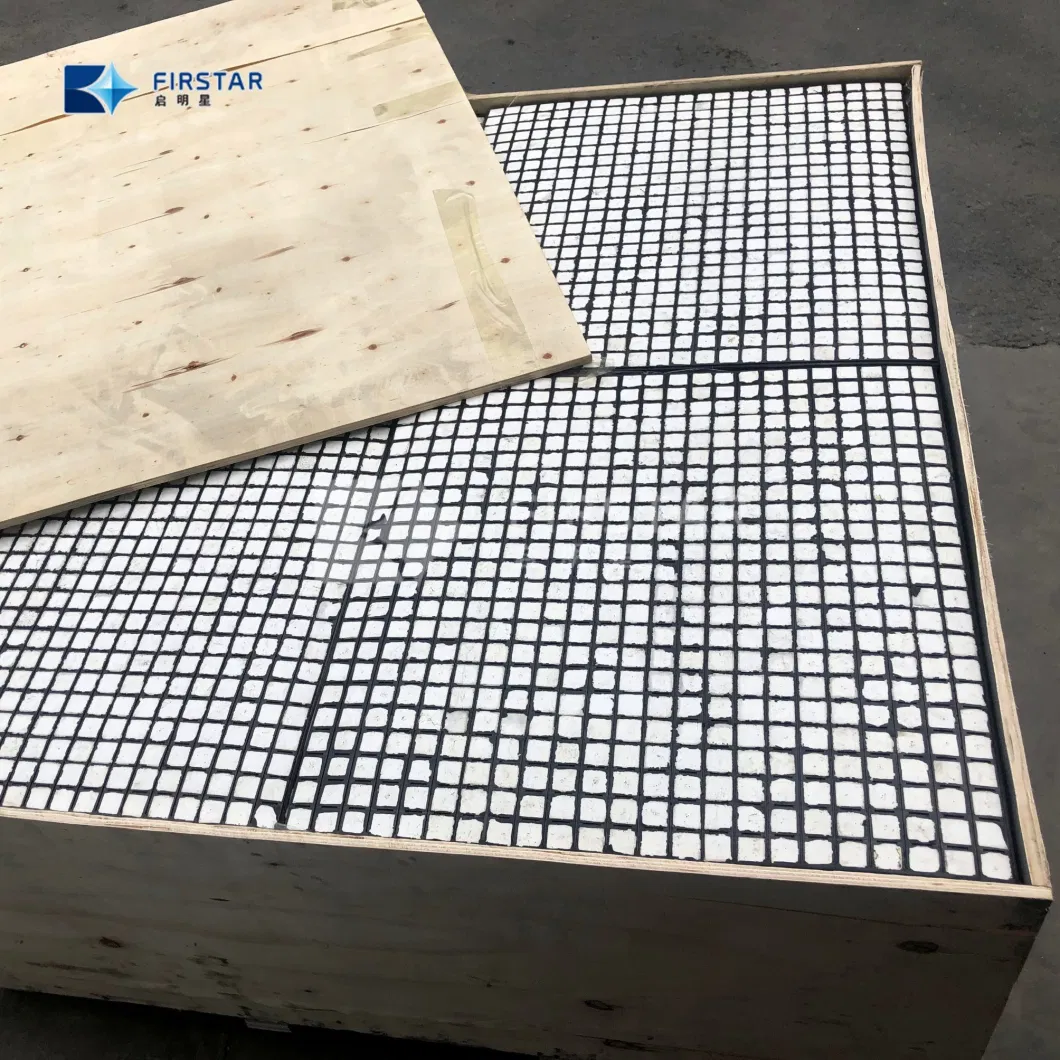

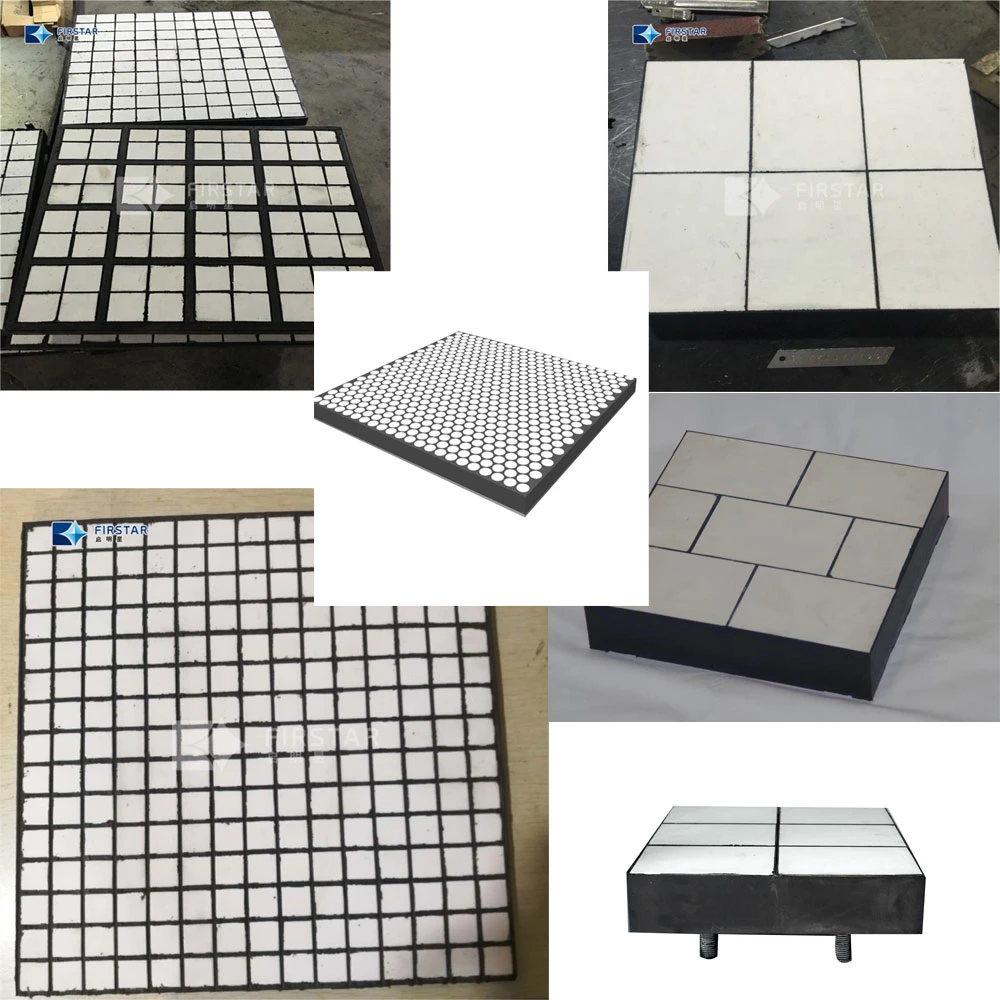

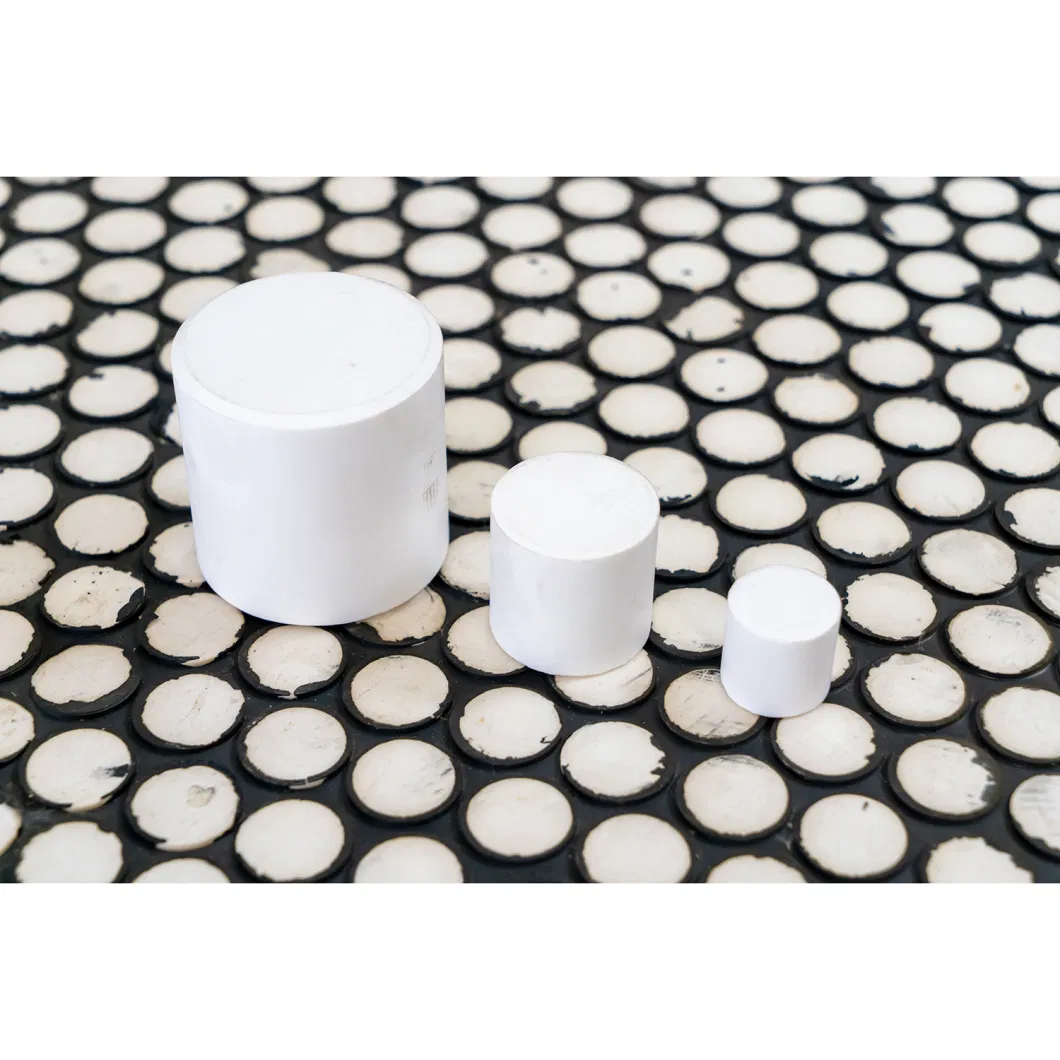

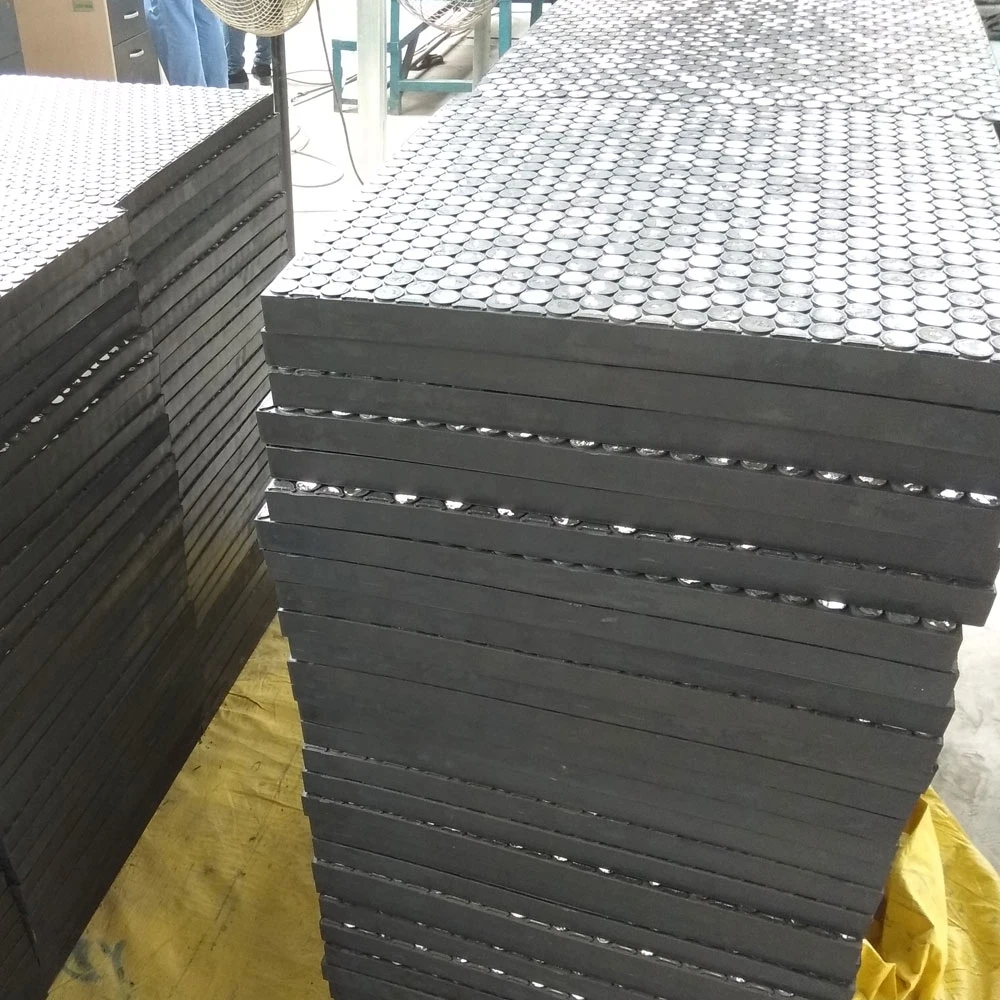

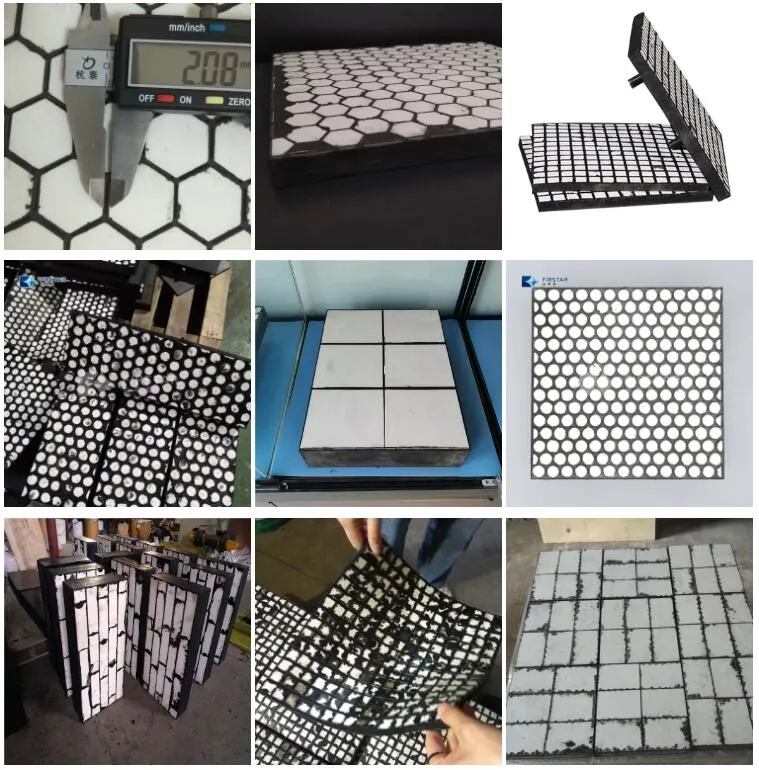

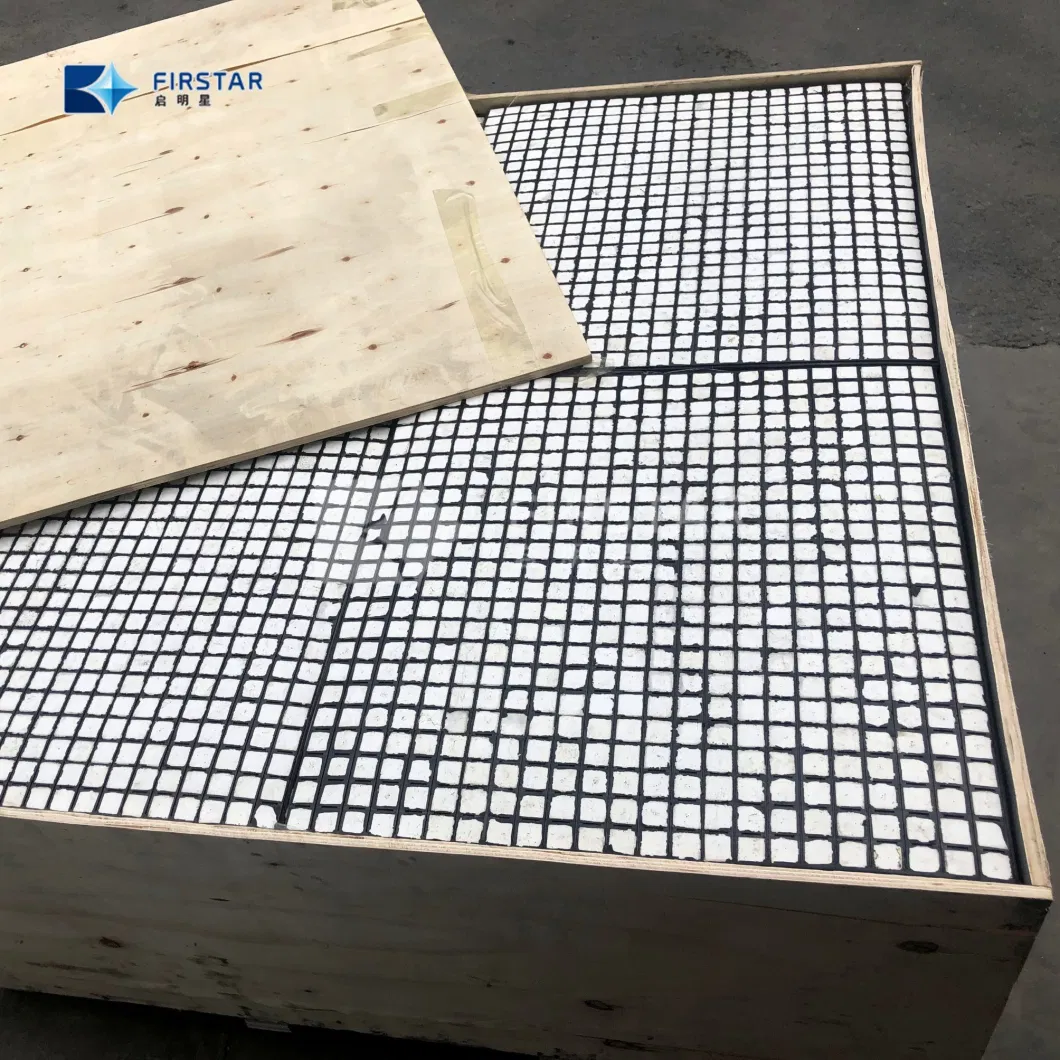

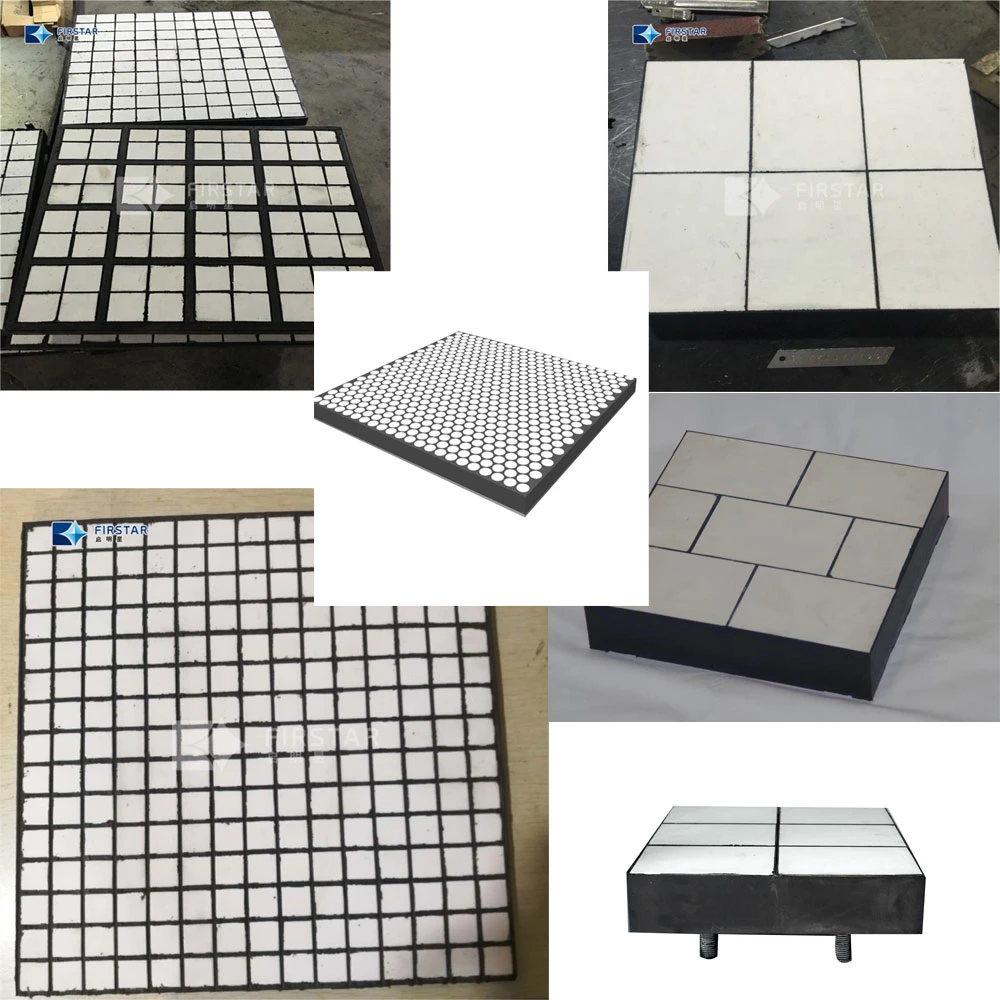

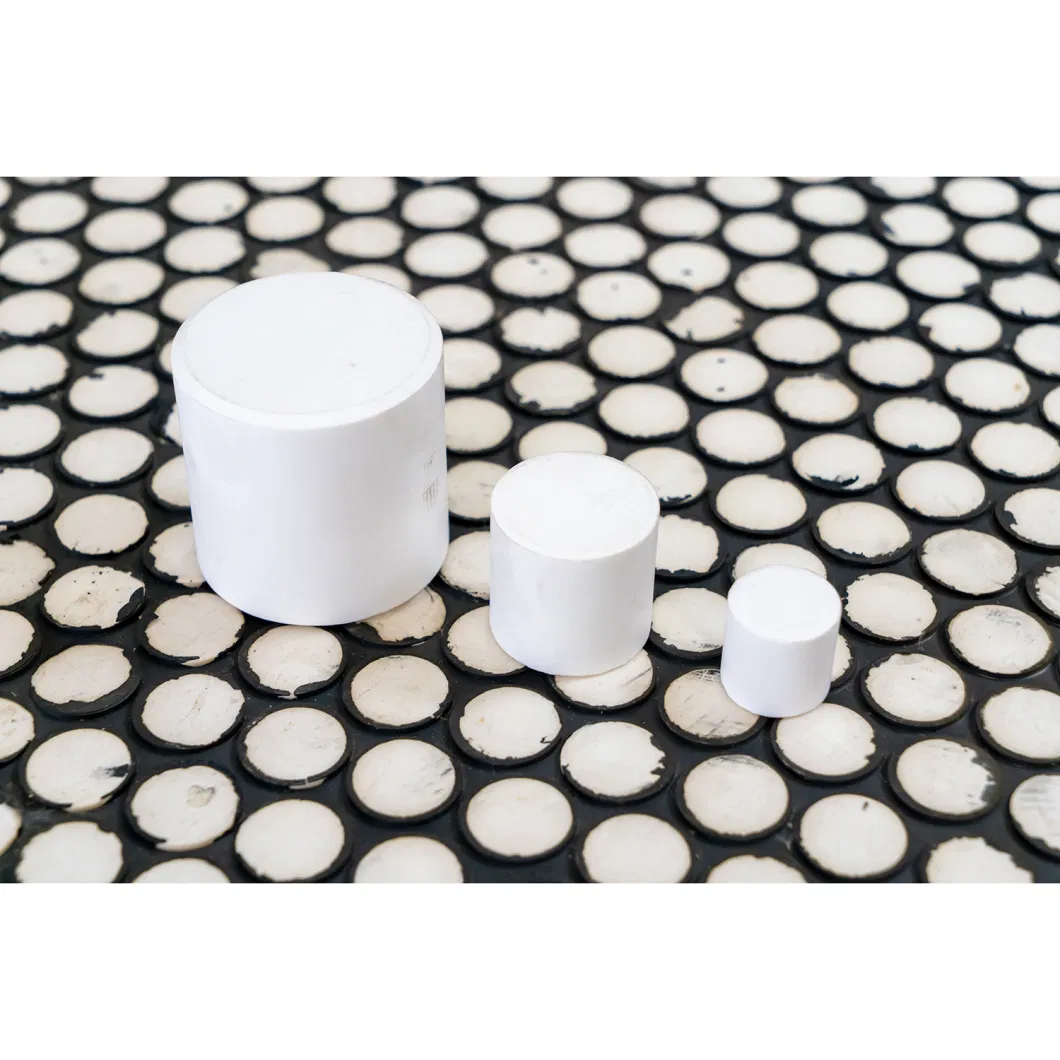

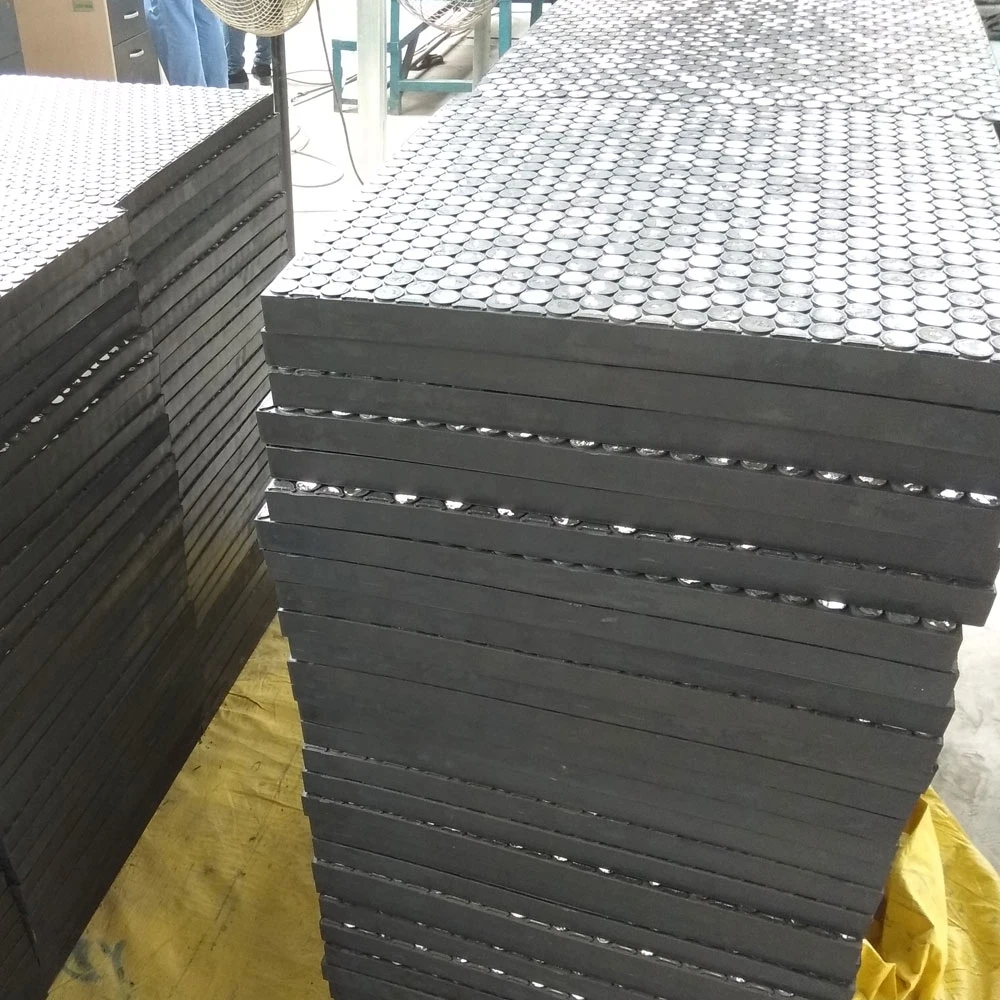

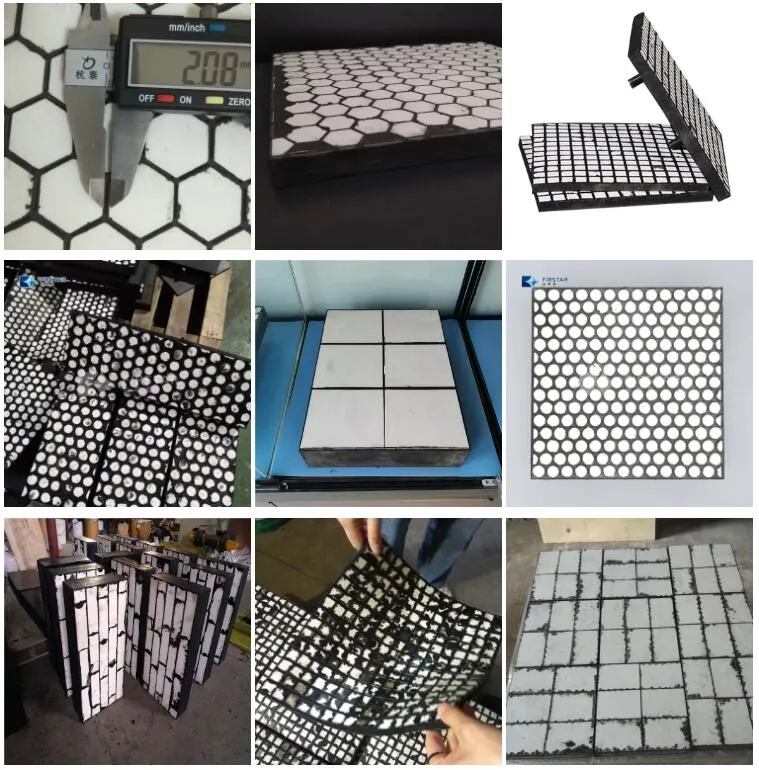

- Detailed Photos

- FAQ

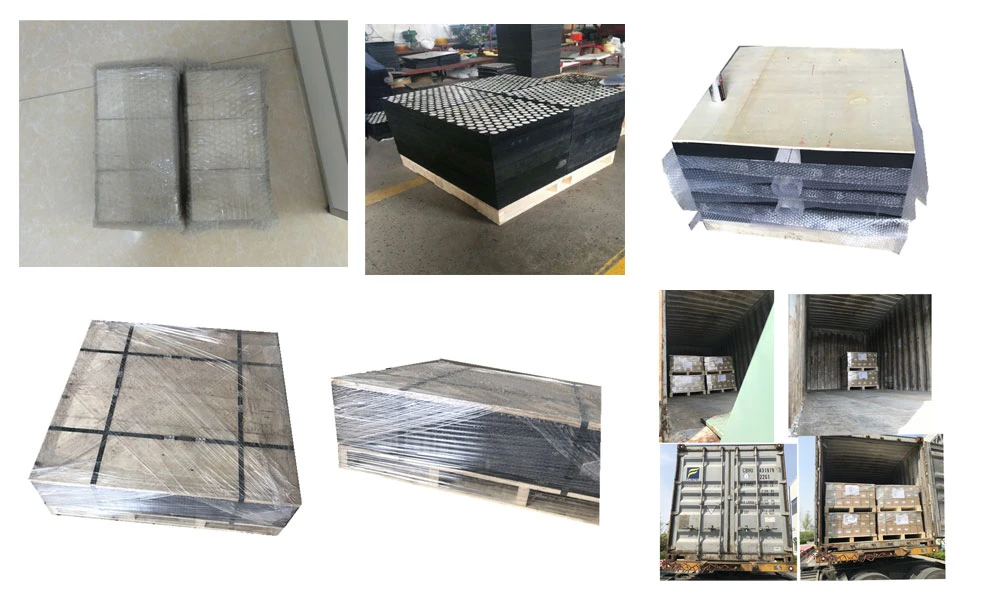

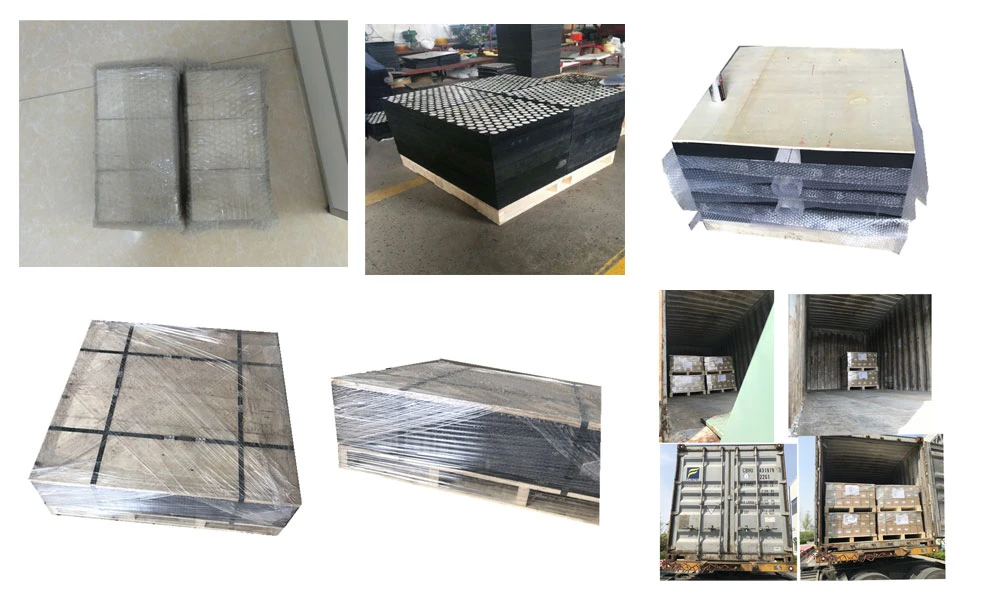

- Packaging & Shipping

- Company Profile

- Certifications

Basic Info.

Density

3.6-4.2g/cm3

Gpa

>1400

Shipping Way

Fob, CIF, DDP, DDU etc

Size

Max 900*900

Certificate

SGS, ISO

Export Markets

Australia, South Africa, South America,Global

Certification

SGS, ISO

Function

Wear Abrasion Resistant

Sample Time

2-5 Days

Bulk Order Time

10-30 Days

Customized

Accept

Use

Chute Wear Resistant

Key Words

Rubber Mats

Transport Package

Pallet or Wooden Box

Specification

Al2O3 over 99%

Trademark

ZIBO QIMINGXING NEW MATERIAL

Origin

China Shandong Zibo

HS Code

6909120000

Production Capacity

17000 Tons Per Year

Product Description

High alumina hard alloy ceramic liner with rubber back plate

Ceramic rubber mats offer good protection to wear areas, which is manufactured by rubber or polyurethane,alumina ceramic tiles and steel backing plate through hot vulcanizing process.

Features of ceramic rubber composite liner:

• high alumina ceramic offers excellent wear resistant.

• rubber layer prevents ceramic tiles breakage.

• available with stud bolt and weldable installation methods or CN bonding layer

• various shape and size of ceramic, bricks, cylindrical, etc.

• rich experiences and strict QC ensures high quality.

Applications:

Pipes and tanks

Deflectors

Launders

Spill Face Sloping Walls&Loading Chutes

Bins&Hoppers

Mill feed components

Mineral Processing equipment operates in some of the harshest and remote locations. It is crucial to the Mineral Processing industries that this equipment continues to operate efficiently and its lifecycle is maximized to minimize downtime. By appropriately protecting equipment from the extreme wear caused by the high speed and flow rates of ore when processed as a slurry ensures better equipment longevity. The slurry is highly abrasive and can not only cause wear damage to wet processing equipment but also with the inclusion of chemicals and heat, there is a constant risk of corrosion and dangerous leakage.

Wear Protection ceramic Linings are used throughout Mineral Processing to protect the steel surfaces of equipment from wear and corrosion. They are used on a range of equipment including pipes, tanks, chutes, pumps, flotation cells, thickeners, launders, and feed spouts or chutes.

1. Established in 1997,20 years experience in wear solutions products.

2. The factory is under expanding, the total construction area is 50,000 sqm.

3.ISO9001:2000 certified,over 260 staffs.

4. Three Own-designed production lines, the ball mils are own produced.

Picture of workshop production

The company specializes in the production of HC series wear-resistant ceramic liners(alumina ball, zirconium silicate ball, zirconia toughed alumina ball, zirconium ball), agate ball, polyurethane ball, 92/T95/ZTA wear-resistant ceramic liner (alumina liner, zirconium toughed aluminum composite liner, zirconia plate), three-in-one,Two-in-one vulcanized ceramic runner sheet,ceramic mending compound, ceramic lining cyclone, ceramic lining pipe.

| Rubber wear liner size: 500*500*6mm,500*500*8mm,500*500*10mm,500*500*12mm Ceramic: Square tiles 17.5*17.5mm or 20*20mm | ||

| 92 Alumina Ceramic Liners | WEAR PLATE BACKING MATERIALS | Mild Steel Backing Plate |

| Al2O3:≥92% Density:≥3.6g/cm³ Porosity:<0.25 compressive strength:≥1050Mpa Rockwell Hardness ≥85.5HRA Vickers Hardness Hv20: ≥1050Mpa Fracture Toughness(KIC): ≥3.7MPa.m1/2 Bending strength: ≥220Mpa Wear Volume:≤0.25cm3 Appearance: white | Rubber:Natural Tensile strength(TSB):≥15Mpa Shore A Hardness: 55-60 Thermal conductivity.(normal temperature): 2w/m·k Adhesive between Ceramic and rubber: 3.8Mpa Elongation: 468% Resilience:0.65 | Steel: Q235A or Q235B Q235A: C 0.14-0.22% Mn 0.30-0.65% Si≤0.30 S≤0.050 P≤0.045 Q235B: C 0.12-0.20% Mn 0.30-0.670% Si≤0.30 S≤0.045 P≤0.045 |

Ceramic rubber mats offer good protection to wear areas, which is manufactured by rubber or polyurethane,alumina ceramic tiles and steel backing plate through hot vulcanizing process.

Features of ceramic rubber composite liner:

• high alumina ceramic offers excellent wear resistant.

• rubber layer prevents ceramic tiles breakage.

• available with stud bolt and weldable installation methods or CN bonding layer

• various shape and size of ceramic, bricks, cylindrical, etc.

• rich experiences and strict QC ensures high quality.

Applications:

Pipes and tanks

Deflectors

Launders

Spill Face Sloping Walls&Loading Chutes

Bins&Hoppers

Mill feed components

Mineral Processing equipment operates in some of the harshest and remote locations. It is crucial to the Mineral Processing industries that this equipment continues to operate efficiently and its lifecycle is maximized to minimize downtime. By appropriately protecting equipment from the extreme wear caused by the high speed and flow rates of ore when processed as a slurry ensures better equipment longevity. The slurry is highly abrasive and can not only cause wear damage to wet processing equipment but also with the inclusion of chemicals and heat, there is a constant risk of corrosion and dangerous leakage.

Wear Protection ceramic Linings are used throughout Mineral Processing to protect the steel surfaces of equipment from wear and corrosion. They are used on a range of equipment including pipes, tanks, chutes, pumps, flotation cells, thickeners, launders, and feed spouts or chutes.

Q: Are you a trading company or manufacturer?

A: We are a factory.

Q: Is the sample free?

A: Yes, we offer free samples.

The sample air shipping fee will be returned when the bulk order.

Q: Is the sample free?

A: Yes, we offer free samples.

The sample air shipping fee will be returned when the bulk order.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: What are your terms of payment?

A: T/T 30% as the deposit, the balance against copy of B/L after shipment.

1. Established in 1997,20 years experience in wear solutions products.

2. The factory is under expanding, the total construction area is 50,000 sqm.

3.ISO9001:2000 certified,over 260 staffs.

4. Three Own-designed production lines, the ball mils are own produced.

Picture of workshop production

The company specializes in the production of HC series wear-resistant ceramic liners(alumina ball, zirconium silicate ball, zirconia toughed alumina ball, zirconium ball), agate ball, polyurethane ball, 92/T95/ZTA wear-resistant ceramic liner (alumina liner, zirconium toughed aluminum composite liner, zirconia plate), three-in-one,Two-in-one vulcanized ceramic runner sheet,ceramic mending compound, ceramic lining cyclone, ceramic lining pipe.