- Overview

- Our Advantages

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

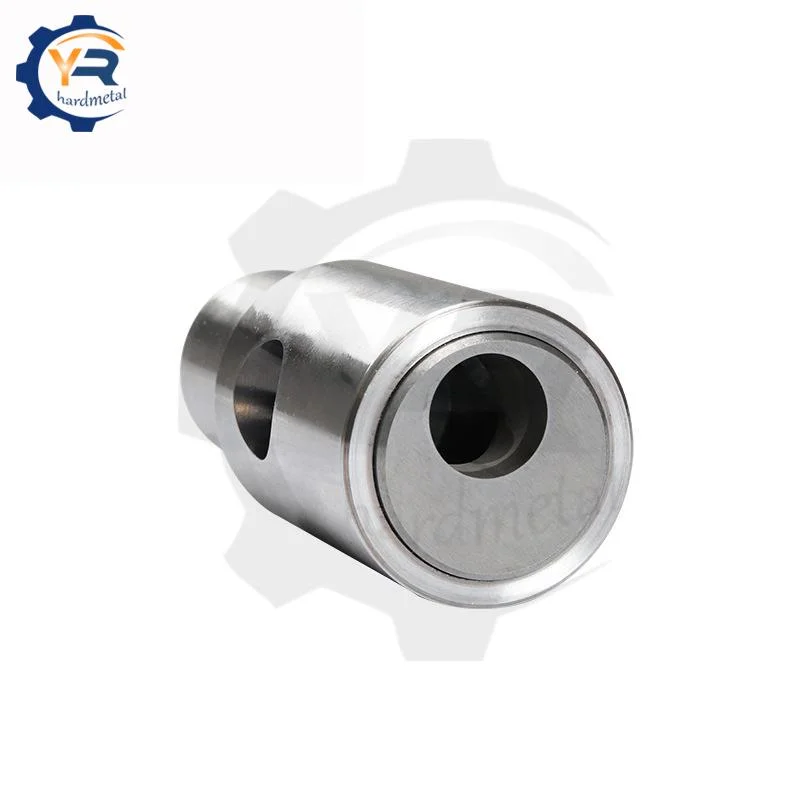

Tungsten carbide Valve core and valve seat sleeve for Flow Control in Oil Industry

Tungsten carbide Valve core and valve seat sleeve for Flow Control in Oil Industry Tungsten carbide valve core seat refers to a component used in valve systems, particularly in industrial and high-pressure applications. Tungsten carbide is a hard and wear-resistant material known for its durability and ability to withstand harsh conditions. Valve core seats made from tungsten carbide are used to provide a tight and long-lasting seal between the valve core and the valve body, preventing leaks and ensuring the proper functioning of the valve.

Here's a brief overview of the key aspects of a tungsten carbide valve core seat:

Material: Tungsten carbide is a compound composed of tungsten (W) and carbon (C) atoms. It is extremely hard, making it suitable for use in applications where wear resistance and durability are essential.

Function: The valve core seat is a crucial part of a valve assembly, serving as the sealing surface against which the valve core (plunger or ball) closes to control the flow of fluids or gases. Tungsten carbide valve core seats are designed to withstand the high pressures and abrasive conditions often encountered in industrial processes.

Features: Tungsten carbide valve core seats are known for their exceptional hardness, corrosion resistance, and resistance to abrasion and wear. These properties make them suitable for use in valves that handle abrasive or corrosive fluids. Additionally, they have a long service life, reducing the need for frequent maintenance or replacement.

Applications: Tungsten carbide valve core seats are commonly used in industries such as oil and gas, chemical processing, mining, and manufacturing, where reliable and long-lasting valve performance is critical. They are often found in ball valves, gate valves, globe valves, and other types of industrial valves

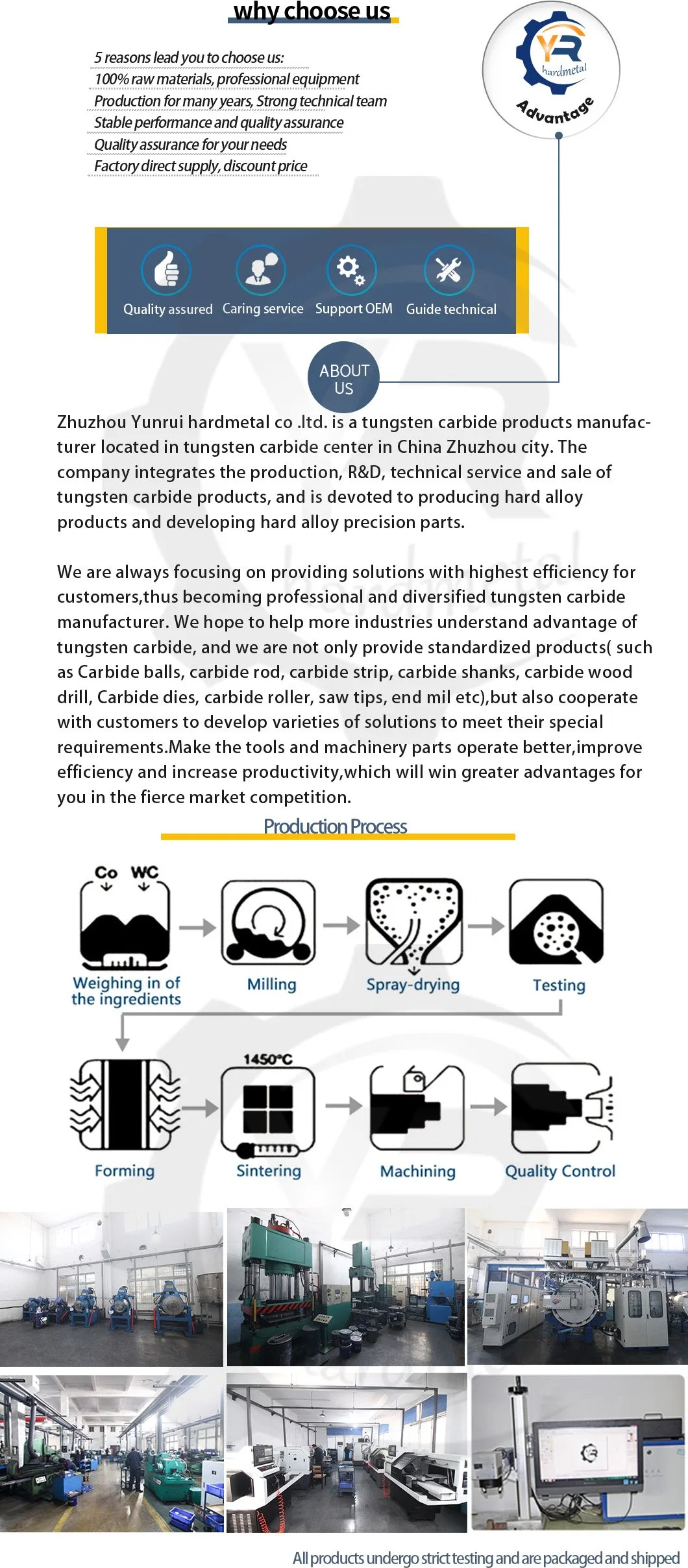

1, Are you a trade company or a manufacturer?

Has been a professional manufacturer for over 15 years to undertake design and processing of all types of tungsten carbide productions service and technical support for customers.

2,Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is base tungsten carbide products.

3,If I need a sample for pretest, do you sale sample for this inquiry?

Yes,we can sale sample for pretest. If you need this service,please contact us.

4,Can you produce the products according to my own drawing?

Yes, we can do OEM according to your requirement.

5,Are the products high quality?

Yes. All order will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

6,How long will it take to execute my order?

For the stock items, we can arrange the shipment within 3-5 days after received your payment. For the customized items, we will indicate the delivery time in the quotation sheet.

7,How can I know how my order is being done?

We will inspect and test all merchandise in case of damage and missing parts before shipping. The detailed inspection pictures of the order will be sent to you for your confirmation before delivery.

8,Can you give warranty of your products?

Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you a re not pleased with TDOER 's quality or service. For the overseas orders, if there is quality problem, please k ind to provide the pictures to show the problems by e-mail . We will provide the replacements to you at our cost according to actual conditions.