- Overview

- Product Description

- Detailed Photos

Basic Info.

Product Description

Hot Sale YG6 solid wood hardwood cutting tungsten carbide saw tips woodworking cemented carbide saw tips

1, cemented carbide cutting saw blade used for hardwood, recycled wood and aluminum alloy.

2, cemented carbide cutting saws for plywood, density plates and sandwich plates.

3, carbide cutting saw suitable for steel.

1. Production of 0.4 um ultrafine tungsten carbide.

2. The hardness of the product is as high as 93.5. it has good wear resistance.

3. High frequency welding of welding wire.

Product Name | Carbide saw tips used for cutting |

Material | Co+WC 100% Virgin Raw Materials |

Color | Nickel white/Black/Gray |

Standard | DIN GB ISO JIS BA ANSI |

Used | Brazed on the wood-working saw blade for cutting |

|

|

Features of cemented carbide saw tips blades

Grade | Physical and mechanical properties | ISO Code | Applications recommended | Proposal for welding | ||

Density g/cnV | Hardness HRA(HV) | TRS Mpa | ||||

YG6 | 14.6- 15.0 | ≥90.0 | ≥ 1800 | K20 | For the cutting of ordinary wood | use resistance welding.and the temperature should be not too high |

YG8 | 14.6- 14.9 | ≥89.5 | ≥1900 | K30 | For the cutting of ordinary wood, also for aluminum | use resistance welding.and the Temperature should be not too high |

EG20 | 14.4- 14.7 | ≥90.0 | ≥ 2000 | K20 | For the cutting of ordinary wood | use resistance welding.and the temperature should be no too high |

eg25 | 14.3- 14.6 | ≥ 89.5 | ≥2100 | K30 | For the cutting of ordinary wood, also for aluminum | use resistance welding.and the Temperature should be not too high |

eg5 | 14.6 -15.0 | ≥90.5 | ≥1900 | K10 | Applies to the cutting of hard wood, recycling wood and aluminum | use resistance welding.and the remperature should be not too high |

JX9 | 14.5 -14.9 | ≥90.5 | ≥ 2000 | K10 | Applies to the cutting of aluminum opperand lesd.non-ferrous | recommend the high-frequency welding |

YG6X | 14.7 -15.0 | ≥92 | ≥ 1800 | K10 | Applies to the cutting of the timber | recommend the high-frequency welding |

eg05 | 14.8 -15.1 | ≥93.3 | &2500 | K05 | Applies to the cutting of hard Wood, also can be used for The cutting of soft metal | recommend the high-frequency welding |

eg15 | 14.6 -15.0 | ≥92.5 | ≥ 2400 | K05 | Applies to the cutting of mard wood and aluminum | recommend the high-frequency welding |

eg35 | 14.9 -15.2 | ≥ 93.5 | ≥ 2000 | K01 | Apply to the cutting of plywood, mdf board and sandwich board | recommend the high-frequency welding |

eg40 | 12.8 -13.2 | ≥ 90.5 | ≥ 2000 | P40 | Apply to the cutting of steel | recommend the high-frequency welding |

1. Production of 0.4 um ultrafine tungsten carbide.

2. The hardness of the product is as high as 93.5. it has good wear resistance.

3. High frequency welding of welding wire.

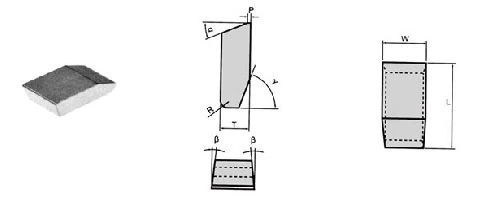

Saw tips-European style

| LxWxT(mm) | α° | γ° | β° | ||

| L | W | T | |||

| 7.5 | 2.5 2.8 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.5 5.2 6.0 | 2.5 | 28 | 70 | 5 |

| 7.5 | 2.8 3.2 3.5 3.7 4.5 5.0 5.6 6.0 6.5 | 2.4 | 30 | 50 | 0 |

| 8.0 | 2.4 2.8 2.9 3.0 3.1 3.2 3.3 3.1 3.5 3.6 3.8 3.9 4.0 | 2.3 | 28 | 70 | 5 |

| 8.0 | 4.3 4.4 4.5 4.8 5.0 5.2 5.5 6.0 6.8 8.0 | 2.5 | 28 | 70 | 5 |

| 8.0 | 2.8 3.0 3.3 3.5 3.8 4.1 4.2 4.6 5.0 5.2 5.5 10.0 | 3 | 25 | 45 | 0 |

| 8.5 | 2.8 3.0 3.3 3.4 3.5 3.6 3.8 4.1 4.2 4.3 4.6 5.0 6.0 | 2.5 | 28 | 70 | 5 |

| 9.0 | 3.6 4.3 4.5 5.2 5.5 | 2.7 | 28 | 45 | 5 |

| 9.0 | 3.1 3.3 3.5 3.6 3.8 4.3 4.5 4.7 5.2 5.5 2.8 6.0 | 2.7 | 28 | 70 | 5 |

| 10.0 | 3.4 3.5 4.3 6.5 | 2.5 | 20 | 68 | 0 |

| 10.0 | 3.5 3.7 3.9 4.0 4.3 4.5 4.7 5.0 5.5 6.0 | 2.8 | 28 | 70 | 5 |

Saw tips-European style

| LxWxT(mm) | α° | γ° | β° | ||

| L | W | T | |||

| 10.0 | 6.5 7.0 7.5 10.0 | 2.8 | 28 | 70 | 5 |

| 10.0 | 3.5 3.8 4.3 4.5 4.7 4.8 5.0 5.3 5.4 5.5 6 | 3 | 15 | 72 | 0 |

| 10.5 | 3.0 3.5 3.8 7.0 | 2.3 | 28 | 70 | 5 |

| 10.5 | 3.0 3.3 3.4 3.5 3.6 3.8 4.0 4.1 4.3 4.4 | 2.5 | 28 | 70 | 5 |

| 10.5 | 4.5 4.6 5.2 5.5 6.5 | 2.5 | 28 | 70 | 5 |

| 10.5 | 3.0 3.4 3.5 3.6 3.8 4.1 4.3 4.5 4.6 4.7 | 3 | 28 | 70 | 5 |

| 10.5 | 4.8 5.0 5.3 5.5 5.6 6.0 6.5 7.0 7.5 14.5 | 3 | 28 | 70 | 5 |

| 10.5 | 3.5 3.9 4.0 4.2 4.3 4.4 4.5 4.6 4.7 4.8 | 3.5 | 28 | 70 | 5 |

| 10.5 | 5.0 5.3 5.5 5.8 6.0 6.5 7.0 8.0 8.5 9.0 10.5 | 3.5 | 28 | 70 | 5 |

| 10.5 | 3.5 3.9 4.0 4.1 4.3 4.5 4.7 4.8 4.9 5.1 | 3.5 | 39 | 59 | 5 |

| 10.5 | 5.5 6.5 6.5 7.0 9.0 | 3.5 | 39 | 59 | 5 |

| 10.5 | 4.1 4.8 5.0 5.5 6.0 6.5 7.5 8.5 9.5 11.0 | 3.5 | 30 | 75 | 0 |

| 12.0 | 4.5 4.6 4.7 5.1 5.5 5.8 6.0 6.3 6.5 7.0 | 3.5 | 30 | 45 | 10 |

| 12.0 | 8.0 8.5 10 12.5 17.0 | 3.5 | 30 | 45 | 10 |

Saw tips-European style

| LxWxT(mm) | α° | γ° | β° | ||

| L | W | T | |||

| 12.5 | 4.0 4.5 4.8 5.0 5.4 5.5 5.9 6.2 6.3 6.5 7.0 7.5 10.1 | 3.0 | 28 | 70 | 5 |

| 12.5 | 4.8 5.2 5.3 5.4 6.0 6.3 6.5 6.8 7.0 7.5 | 3.5 | 28 | 70 | 5 |

| 12.5 | 4.5 5.0 5.5 6.0 6.3 6.5 6.8 7.0 7.5 8.0 9.5 12.5 | 4.0 | 30 | 70 | 5 |

| 13.0 | 4.0 4.3 4.5 5.0 5.2 5.5 5.8 6.0 6.3 6.5 | 4.0 | 30 | 45 | 5 |

| 13.0 | 7.0 7.5 8.0 8.2 8.5 9.0 10.0 11.0 13.0 | 4.0 | 30 | 45 | 5 |

| 13.0 | 4.4 4.8 4.9 5.2 5.4 5.7 5.8 6.0 6.3 6.5 | 4.0 | 30 | 60 | 5 |

| 13.0 | 6.7 7.0 7.5 8.5 10.0 | 4.0 | 30 | 60 | 5 |

| 13.0 | 4.0 4.5 4.8 4.9 5.0 5.3 5.5 6.0 6.5 6.8 | 4.0 | 40 | 60 | 3 |

| 13.0 | 7.0 7.5 8.0 8.5 10.0 | 4.0 | 40 | 60 | 3 |

| 13.0 | 5.0 6.0 7.0 8.0 9.0 10.0 12.0 | 5.0 | 35 | 45 | 0 |

| 14.5 | 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 | 4.0 | 30 | 70 | 0 |

| 14.5 | 10.0 11.0 12.0 12.2 13.0 14.0 14.2 15.0 16.0 | 4.0 | 30 | 70 | 0 |

| 14.5 | 16.2 17.0 18.0 19.0 20.0 | 4.0 | 30 | 70 | 0 |

| 15.5 | 8.0 9.5 12.0 13.0 | 5.0 | 30 | 0 | 0 |

Saw tips U.S-Canadian style

| Code | (inch) | ||

| L | W | T | |

| CWB 7050-CWB 7500 | 0.281 | .050-.500 | 0.78 |

| CWD 7050-CWD 7500 | 0.312 | .050-.500 | 0.093 |

| CWE 7050-CWE 7500 | 0.375 | .050-.500 | 0.093 |

| CWF 7050-CWF 7800 | 0.5 | .050-.800 | 0.125 |

| CWG 7050-CWG 7800 | 0.375 | .050-.800 | 0.125 |

| CWH 7050-CWH 7800 | 0.344 | .050-.800 | 0.125 |

| Code | (inch) | ||

| L | W | T | |

| WA 7050-WA 7500 | 0.250 | .050-.500 | 0.062 |

| WB 7050-WB 7500 | 0.281 | .050-.500 | 0.078 |

| WC 7050-WC 7500 | 0.281 | .050-.500 | 0.093 |

| WD 7050-WD 7800 | 0.312 | .050-.800 | 0.093 |

| WE 7050-WE 7800 | 0.375 | .050-.800 | 0.093 |

| WF 7050-WF 7800 | 0.500 | .050-.800 | 0.125 |

| WG 7050-WG 7800 | 0.375 | .050-.800 | 0.125 |

| WH 7050-WH 7800 | 0.344 | .050-.800 | 0.125 |

| WQ 7050-WQ 7800 | 0.375 | .050-.800 | 0.156 |

| Code | (inch) | ||

| L | W | T | |

| WA 8050-WA8500 | 0.250 | .050-.500 | 0.062 |

| WB 8050-WB8500 | 0.281 | .050-.500 | 0.078 |

| WC 8050-WC8500 | 0.281 | .050-.500 | 0.093 |

| WD 8050-WD8800 | 0.312 | .050-.800 | 0.093 |

| WE 8050-WE8800 | 0.375 | .050-.800 | 0.093 |

| WF 8050-WF8800 | 0.500 | .050-.800 | 0.125 |

| WG 8050-WG8800 | 0.375 | .050-.800 | 0.125 |

| WH 8050-WH8800 | 0.344 | .050-.800 | 0.125 |

| WQ 8050-WQ8800 | 0.375 | .050-.800 | 0.156 |

| Code | (inch) | ||

| L | W | T | |

| CWD-R/T7050-7500 | 0.312 | .050-.500 | 0.093 |

| CWE-R/T7050-7500 | 0.375 | .050-.500 | 0.093 |

| CWF-R/T7050-7500 | 0.500 | .050-.500 | 0.125 |

| CWG-R/T7050-7500 | 0.375 | .230-.270 | 0.125 |

Usage Purpose

Contact;

Emma

Mobile+86-199733339509