Basic Info.

Model NO.

Precision Machining

Trademark

Guangmei

Origin

China

HS Code

8514909000

Production Capacity

100000PCS/Year

Product Description

Precision machined part parameter

| Summary of the company's products | |

| Manufacture | Qingdao GuangMei Precision Machinery co.,Ltd |

| Main processing products | precision fixture processing, precision machinery axle processing,spare parts,machined part. |

| Material | Q235,S25C,S45C,S50C,S55C,SUS440C,SCM415, SUS304,SUS316,SUS303,A5052,A6061,A7075, SUJ2,SKD11,SKS3 |

| Surface Roughness | Ra0.4mm~ |

| Concentricity | ±0.005mm |

| Straightness | ± 0.02mm |

| Precision | ±0.003mm |

| Surface Treatment | TiCN,TiN,Aitain,Ticrn,Dlc,Ni coating,Black coating ,Cr couting,etc |

| Hardness | HRC20-60 |

| Standard | JIS,DIN,ASTM/AISI international industrial standard |

| MOQ | 1 Piece |

| Supply Capability | 10000 pieces/Month |

| Delivery way | EMS,OCS,DHL,UPS,FEDEX,Shipping |

Main service areas

Precision machined part Application Area

| Main Equipment | |||||

| NO | Equipment Name | BRAND TYPE | QT,Y | UNIT | NOTE |

| 1 | WIRE CUTTING | MITSUBISI FA10S | 1 | SET | |

| 2 | SUPPER DRILL | SUPPER DRILL | 1 | SET | |

| 3 | EDM | CREATION | 2 | SET | |

| 4 | EDM | SODICK AQ36L | 1 | SET | |

| 5 | EDM | SODICK AD30L | 2 | SET | |

| 6 | MACHINE CENTER | DOOSAN | 1 | SET | |

| 7 | MACHINE CENTER | JIATIE | 1 | SET | |

| 8 | Precision large water mill | PROTH | 1 | SET | |

| 9 | LATHE | CDE6140A | 1 | SET | |

| 10 | NC LATHE | 2 | SET | ||

| 11 | Outer round grinding | 1 | SET | ||

| 12 | Heartless Grinding | 1 | SET | ||

| 13 | GRINDE | CGM-200BS | 1 | SET | |

| 14 | GRINDE | CGM-618VS | 1 | SET | |

| 15 | GRINDE | ZHUNLI 618M | 5 | SET | |

| 16 | GRINDE | 618M | 6 | SET | |

| 17 | LASER MARKING | 1 | SET | ||

| 18 | END MILLING | TOPONE | 2 | SET | |

| 19 | Wanhao Projector AND MITSUTOYO | 200 mm | 3 | SET | |

| 20 | Marble Level Platform | 450× 450 *100mm | 14 | EA | |

| 21 | Tool Microscope | 0.001MM | 3 | SET | |

| 22 | MITSUTOYO Digital micrometer | 0 ~ 25mm,25 ~ 50mm | 5 | EA | |

| 23 | MITSUTOYO Digital micrometer | 150mm, 200mm, 300mm | 6 | EA | |

| 24 | MITSUTOYODial indicator | 1/1000 mm | 10 | EA | |

| 25 | MITSUTOYO HEIGHT GAGE ,NIKON | 300 mm | 10 | EA | |

| 26 | BLOCK GAGE | 1.005mm~100mm | 15 | SET | |

| 27 | Lever micrometer | 1/100 mm | 5 | EA | |

| 28 | Inner diameter percentage meter | 1/100 mm | 3 | EA | |

| 29 | MITSUTOYO External diameter micrometer | 0 ~ 25 mm | 5 | EA | |

Certifications

Company information

Qingdao Guangmei Precision Machinery Co., Ltd. is located on the west side of Xiazhuangkou on the Qingyin Expressway in Liuting Town, Chengyang District, Qingdao City, Shandong Province, China.

The company was established in June 2007, covering an area of approximately 2000 square meters.

We have over 15 years of experience in manufacturing and processing, and are a private enterprise that designs and manufactures precision mechanical parts.

The main business scope of the company:

Processing precision mechanical components, automation non-standard components, precision fixtures

And various precision non-standard CNC lathe machining parts, machining center machining parts, cylindrical grinding parts, shaft machining parts, etc.

Various precision mechanical parts processed from materials such as carbon steel, stainless steel, aluminum, copper, brass, cast nylon, steel, cast iron, etc

And non-standard components for automation.

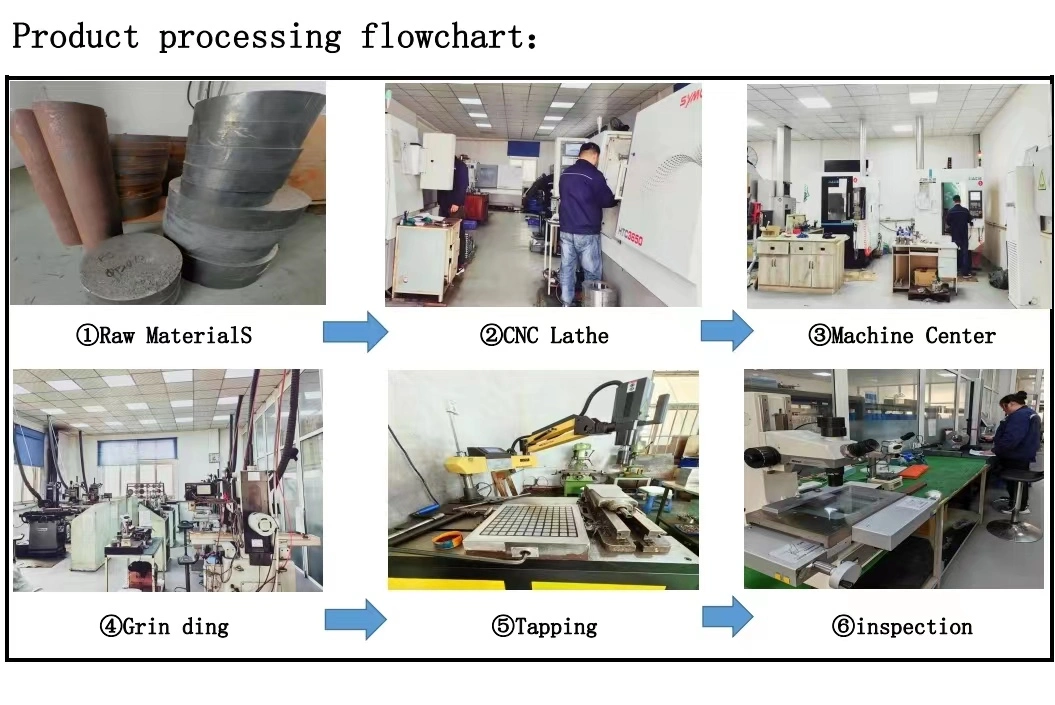

We now have strong manufacturing capabilities:

Including automatic lathes, CNC lathes, CNC machining centers, as well as milling machines, cylindrical grinders, centerless grinders

Auxiliary equipment such as surface grinding machines, high-speed engraving machines, and discharge machining.

Both circular machining and irregular mechanical component machining can be produced.

Factory workshop

Packaging & Shipping

FAQ

1. Are you a manufacturer or a trading company?

We are a professional manufacturer providing precision machining

Precision mechanical components, automated non-standard component processing, and precision mold core processing.

2. Where is your factory?

We are located in Qingdao, Shandong Province, China.

3. What is your processing power?

Capable of processing and manufacturing 1000000 pieces per month. Depending on the specific product output, it can be increased

4.Can you accept OEM and ODM design?

Yes, OEM and ODM are acceptable.

5. How do you ensure quality?

We have strict requirements for our products and have specially arranged QC personnel to conduct process follow-up testing and final testing.

Control the requirements of each process to achieve customer satisfaction.

6. Do you provide sample production?

Our company's production and operation model is' processing with drawings', which is standard or non-standard parts.

The customer needs to provide relevant drawings for the product and arrange production samples according to the drawing requirements.

If you have any requirements, please feel free to provide drawings (product drawings, CAD design drawings, or 3D data).

7. What is the delivery time?

The delivery deadline is determined by the difficulty of the drawings.

Regarding shipment: The arrangement for air transportation takes 3-6 days and sea transportation takes 7-30 days, depending on the transportation in the host country.

The company was established in June 2007, covering an area of approximately 2000 square meters.

We have over 15 years of experience in manufacturing and processing, and are a private enterprise that designs and manufactures precision mechanical parts.

The main business scope of the company:

Processing precision mechanical components, automation non-standard components, precision fixtures

And various precision non-standard CNC lathe machining parts, machining center machining parts, cylindrical grinding parts, shaft machining parts, etc.

Various precision mechanical parts processed from materials such as carbon steel, stainless steel, aluminum, copper, brass, cast nylon, steel, cast iron, etc

And non-standard components for automation.

We now have strong manufacturing capabilities:

Including automatic lathes, CNC lathes, CNC machining centers, as well as milling machines, cylindrical grinders, centerless grinders

Auxiliary equipment such as surface grinding machines, high-speed engraving machines, and discharge machining.

Both circular machining and irregular mechanical component machining can be produced.

Factory workshop

Packaging & Shipping

FAQ

1. Are you a manufacturer or a trading company?

We are a professional manufacturer providing precision machining

Precision mechanical components, automated non-standard component processing, and precision mold core processing.

2. Where is your factory?

We are located in Qingdao, Shandong Province, China.

3. What is your processing power?

Capable of processing and manufacturing 1000000 pieces per month. Depending on the specific product output, it can be increased

4.Can you accept OEM and ODM design?

Yes, OEM and ODM are acceptable.

5. How do you ensure quality?

We have strict requirements for our products and have specially arranged QC personnel to conduct process follow-up testing and final testing.

Control the requirements of each process to achieve customer satisfaction.

6. Do you provide sample production?

Our company's production and operation model is' processing with drawings', which is standard or non-standard parts.

The customer needs to provide relevant drawings for the product and arrange production samples according to the drawing requirements.

If you have any requirements, please feel free to provide drawings (product drawings, CAD design drawings, or 3D data).

7. What is the delivery time?

The delivery deadline is determined by the difficulty of the drawings.

Regarding shipment: The arrangement for air transportation takes 3-6 days and sea transportation takes 7-30 days, depending on the transportation in the host country.