Basic Info.

Product Description

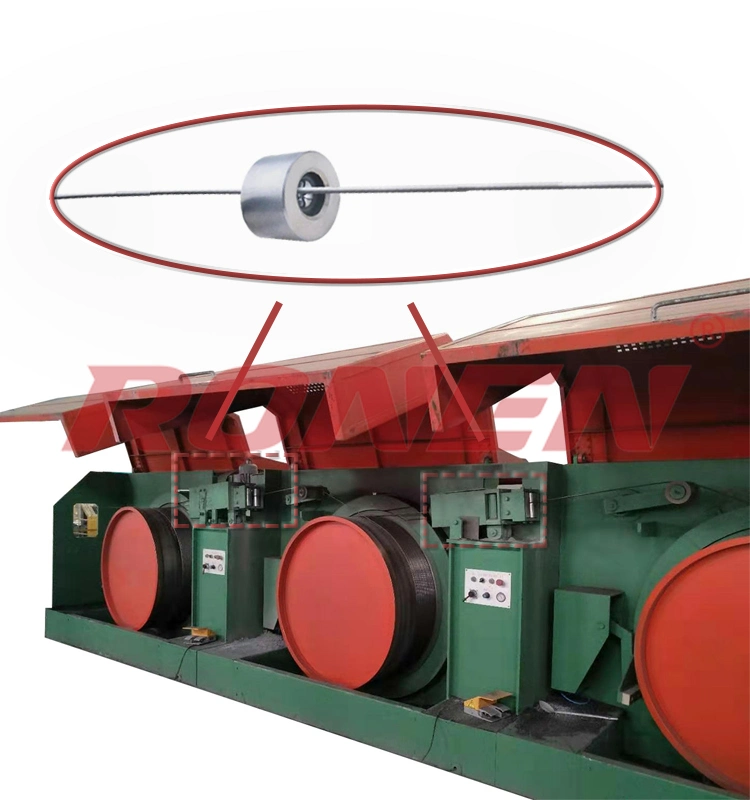

Long Service Life Cemented Carbide Die Core Galvanized Iron Wire Drawing Polycrystalline Diamond Die

Company Introduction Technique Parameter

Technique Parameter | Model Type | Fetures | Range of application |

| Artificial monocrystalline die | Natural diamond, good retentivity of hole roundness and stable quality | 0.01mm-0.70mm fine wires |

| Various shaped artificial diamond dies | Good finish, high precision and strong wear resistance | Gold & silver jewelery, copper wires, zipper flat wires, tooth flat wires, square CP wires, stainless steel shaped wires and other shaped wires |

| Natural diamond drawing die | High-precision wire drawing industry and its correct hole | 0.01mm-1 .5mm various fine metal wires |

| Nano drawing die | Forming a CVD diamond coating on the surface of tungsten carbide die | Strand wire and the drawing of nonferrous metal like copper, aluminum atc. |

| Artificial polycrystalline drawing die | Long service life, more repair times and wide range | 0. 1mm-12.00mm |

| Round carbide drawing die | High wear resistance and high thermal conductivity | 0. 15mm-50mm Drawing of various metal wires, tubings and rods. |

| Various shaped carbide dies | With high-quality cemented carbide as the raw material | Drawing, reducing, scalping and extrusion of copper, alumium, iron, stainless stell, aluminum alloy and other metal wires,tubings and rods |

| Standard Tolerance Corresponding To Diameter | ||

| Diameter(mm) | Tolerance(mm) | Maximum out-of-roundness(mm) |

| <0.020 | +0 -1.5% | 0.5% |

| >0.020~0.025 | +0 -0.0003% | 0.0002 |

| >0.025~0.050 | +0 -0.0004% | 0.0003 |

| >0.050-0.075 | +0 -0.0006% | 0.0004 |

| >0.075~0.100 | +0 -0.0008% | 0.0004 |

| >0.100~0.200 | +0 -0.001% | 0.001 |

| >0.200~0.500 | +0 -0.002% | 0.0015 |

| >0.500~1.000 | +0 -0.003% | 0.002 |

| >1.000-2.000 | +0 -0.004% | 0.0025 |

| >2.000~3.500 | +0 -0.005% | 0.003 |

| >3.500~5.500 | +0 -0.006% | 0.0035 |

| >5.500~8.000 | +0 -0.007% | 0.004 |

| >8.000~10.000 | +0 -0.008% | 0.0045 |

| >10.000~12.000 | +0 -0.010% | 0.005 |

| >12.000~15.000 | +0 -0.012% | 0.006 |

| >15.000~18.000 | +0 -0.014% | 0.007 |

| >18.000~21.000 | +0 -0.016% | 0.008 |

| >21.000~24.000 | +0 -0.018% | 0.009 |

| >24.000~30.000 | +0 -0.020% | 0.010 |

Ronen Group Is committed to designing and manufacturing of induction heating equipment, which are widely used in Machinery, Building Materials,Metallurgy, Paper Making, Automobile Manufacturing and other fields, to fully meet the needs of Steel Pipe Seam Welding,Stainless Steel Pipe Welding, Strip Heating, Vacuum Melting, Copper Pipe Welding, Steel Pipe Annealing, Refrigerator Tube Welding,Metal Heat Treatment, Metal Smelting, Welding, Brazing, Thermal Assembly and other Induction Heating Process Requirements, mainly include Spring Steel Wires, High-Strength Pipe Piles PC Steel Rods / PC Bar, Prestressed Steel Wire, Prestressed Concrete Strand, Rebar, Aluminum-Plastic Pipes, Wires and Cables Production Equipment lines.

Product Description

Our service tenet is that customer' s satisfaction is our target. We sincerely wish to establish a bright and successful future together with partners around the world.

Ronen Group Workshop Show

Ronen Group Exhibition

Certifications

Packing and Shipping

Q: Are you manufacturer?

A:Yes, We are manufacturer.

Q: How to order?

A:Please send us your inquiry by email, send message through Alibaba , Wechat, Whatsapp or others as you want.

Q: What are the payment terms?

A: Pattern :we can accept T/T,Western Union ,Money Gram.

Q: What is the whole business flow cooperation with us?

A: 1.Firstly,send your inquiry to us, make us have learned your requirement

2.We will be drawing a proforma invoice according to your requirement ,and start production after you finished to pay 30% deposit.

3.All of the goods, packing details will be send to buyer after finished production. We will arrange shipment and the buyer finished to pay the balance.

Not only the Good Machine, but also the Most Attentive Service

If any doubt,feel free to contact us with no doubt!

RONEN always here for you!!