- Overview

- Product Description

- Product Specification

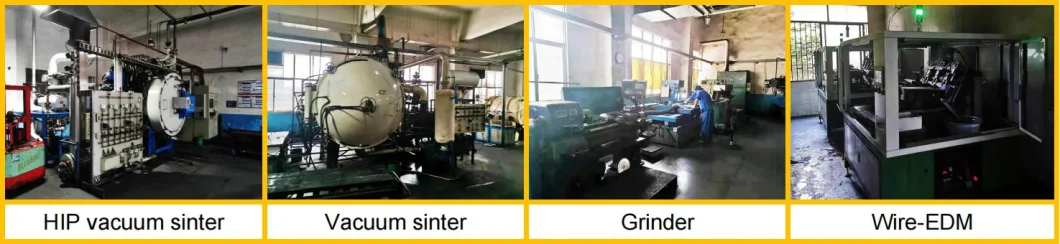

- Production Site

- Packaging

- Reviews From Customers

- Company Profile

- Company Advantage

- FAQ

Basic Info.

Product Description

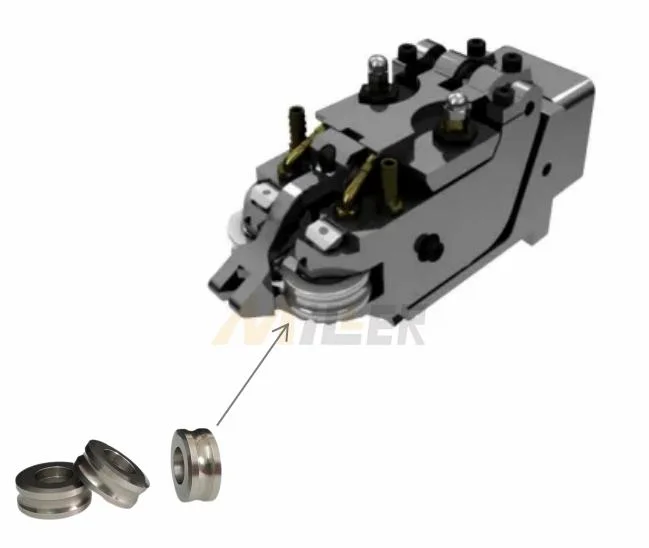

Guide roller is an indispensable device which is installed before and after the hot wire rolling pass to help the rolled piece enter and export the roll pass accurately and stably according to the given direction and state in the rolling process of section steel.

Compared to steel, tungsten carbide is a much more better choice for guide roller due to its high rigidity, good wear resistance (the service life is matched with the high-quality bearing), good thermal conductivity, a certain of red hardness. And the life of WC rollers is typically more than 10 times longer than steel rollers.

Availbable Guider Roller Types

| Flat Type | Double Flanged | Single Flanged | With Trapezoid Groove | With R Groove | V Groove | Tapered Type |

Miller MC15 the hardness is a "built-in" characteristic and not the result of processes like heat-treatment, plating or nitriding. In this case the product is a true hard-metal in which a hardness of approximately 86HRA (approx. 70HRC) is reached by sintering. They are non-magnetic, non-heat treatable and cannot be turned by lathe, but must be grounded by diamond wheels.

Material Material | Miller MT10 | T.C | Tool Steel |

Binder | Alloy Steel | Co-Ni | Fe |

Hard Phase | TiC | WC | Fe3C |

Manufacturing Process | Powder Metallurgy | Powder Metallurgy | Casting |

Hardness (HRC) Tempered | 68-70 | 68-78 | 55-62 |

Hardness (HRC) Annealed | 45-48 | 68-78 | 20-30 |

Density(g/cm³) | 6.45-6.60 | 14.0-15.0 | 7.8-8.5 |

Bend Strength(N/mm2) | 1650-1850 | 1950-2300 | 580-1000 |

Compressive Strength(N/mm2) | 3500-3800 | 3200-4300 | 2000-2700 |

Miller Carbide is an experienced manufacturer of tungsten carbide customized parts started from 2008. Our products cover carbide grinding jars & mortars, carbide grinding balls, carbide pegs, carbide static & dynamic rings, bead mill disks, carbide stirring rods, carbide static & dynamic jaws, carbide crusher plates, carbide grinding discs, carbide rotors, carbide roll rings, carbide guide rolls, carbide burrs, carbide sleeves & bushings, and other customized wear-resistant components for valve and pumps ect. With years of tungsten carbide engineering and manufacturing experience, we can concentrate our skills to the development of customized products for a wide spread of wear applications in milling & crushing industry.

Unlike other suppliers, Miller operates with three disciplines: Engineering, manufacturing and after sale service support. This means we are able to improve the efficiency of your machine and tools with customized products and direct access to the manufacturer. Miller Carbide works closely with its customers to ensure their requirements are designed efficiently and suitable for application. We can design the components needed from drawings or delivered samples.

We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. We are sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

We Offer You These

| Direct Sales Integrating R&D, production sales and technology | Mold customization Rich molds OEM customization accepted | Adequate equipment grinding/pressing sintering/deep processing | Technical strength 15 years of experience in technical team, research & innovation |

1. How long is your delivery time?

We can arrange the shipment within 3-5 working days upon receipt of your payment for any sintered blanks stocked items. As for the mass production order or the customized products, we will need 10-30 days production leadtime and indicate the delivery time on the Proforma lnvoice.