- Overview

- Product Description

- Specification

- Packaging

- Reviews From Customers

- Company Profile

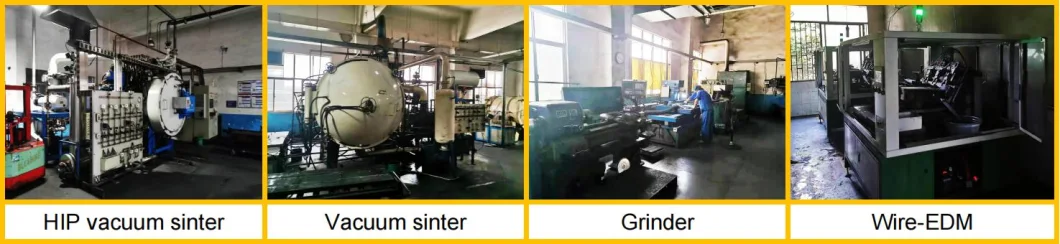

- Company Advantage

- FAQ

Basic Info.

Product Description

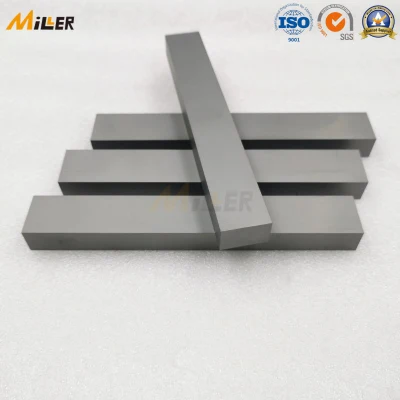

Tungsten Carbide strips and bars for Ore Crushing Machine, in another way sand making machine wear block, belongs to the core part of the vertical impact crusher (sand making machine). crusher hammer are equipped with tungsten carbide strips that protects the rotor of the VSI crusher against wear, mainly used for breaking stone into sand, also widely used in mines, sand, cement, metallurgy, hydropower engineering, ore processing and other industries with its strong wear resistance …

| Base Plate |  | ||||

| Carbide Strip |  | ||||

| Length of Base Plate (mm) | 103 | 196 | 135 | 189 | 320 |

| Size of Carbide Strip (mm) | 52.5x19x10 52.5x23x13 52.5x23x14 | 196x23x15 | 135x23x13 | 189x23x13 189x27x13 189x27x15 | 80x23x13 160x23x13 106x32x14 212x32x14 |

| Base Plate |  | ||||

| Carbide Strip |  | ||||

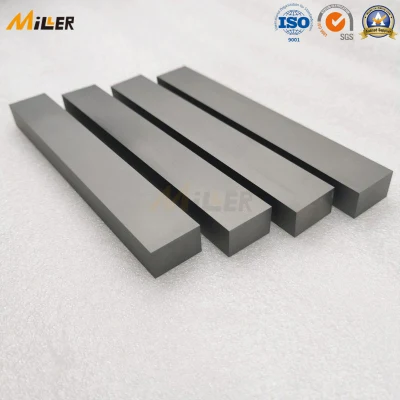

| Length of Base Plate (mm) | 192,142, 92 | 220 | 210 | 189 | 189 |

| Size of Carbide Strip (mm) | 192x10x8 192x13x8 142x10x8 142x13x8 | 220x27x13 220x27x15 | 210x25x15x10 218x23x18x8.5 | 189x27x13 | 189x27x13 |

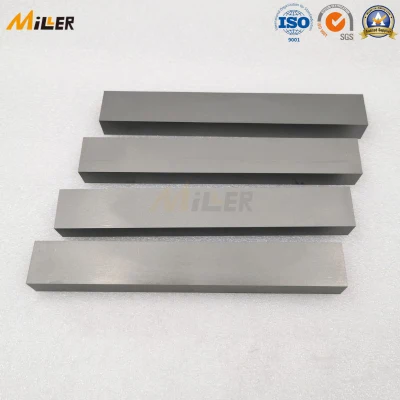

| Base Plate |  | ||||||

| Carbide Strip |  | ||||||

| Size of Carbide Strip (LxWxH mm) | 104x20x12 | 105x20x12 52.5x19x10 52.5x23x12 52.5x23x14 | 192x10x8 192x13x8 | 95.8x15x8 92x10x8 | 99x25x12 | 79x30x12 | 108x23x13 108x20x10 |

| Type for | M20TAP B9100 B7150SE | B6150 B7150 B8100 B9100 B840 | B96394061B | B90394061A | M22DPVI 600 | M10TAP FOR AC10 | RP107 RP108 RP109 |

Miller Carbide is an experienced manufacturer of tungsten carbide customized parts started from 2008. Our products cover carbide grinding jars & mortars, carbide grinding balls, carbide pegs, carbide static & dynamic rings, bead mill disks, carbide stirring rods, carbide static & dynamic jaws, carbide crusher plates, carbide grinding discs, carbide rotors, carbide roll rings, carbide guide rolls, carbide burrs, carbide sleeves & bushings, and other customized wear-resistant components for valve and pumps ect. With years of tungsten carbide engineering and manufacturing experience, we can concentrate our skills to the development of customized products for a wide spread of wear applications in milling & crushing industry.

Unlike other suppliers, Miller operates with three disciplines: Engineering, manufacturing and after sale service support. This means we are able to improve the efficiency of your machine and tools with customized products and direct access to the manufacturer. Miller Carbide works closely with its customers to ensure their requirements are designed efficiently and suitable for application. We can design the components needed from drawings or delivered samples.

We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. We are sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

We Offer You These

| Direct Sales Integrating R&D, production sales and technology | Mold customization Rich molds OEM customization accepted | Adequate equipment grinding/pressing sintering/deep processing | Technical strength 15 years of experience in technical team, research & innovation |

1. How long is your delivery time?

We can arrange the shipment within 3-5 working days upon receipt of your payment for any sintered blanks stocked items. As for the mass production order or the customized products, we will need 10-30 days production leadtime and indicate the delivery time on the Proforma lnvoice.