- Overview

- Product Description

- Application

- Packaging & Shipping

- Our Advantages

Basic Info.

Product Description

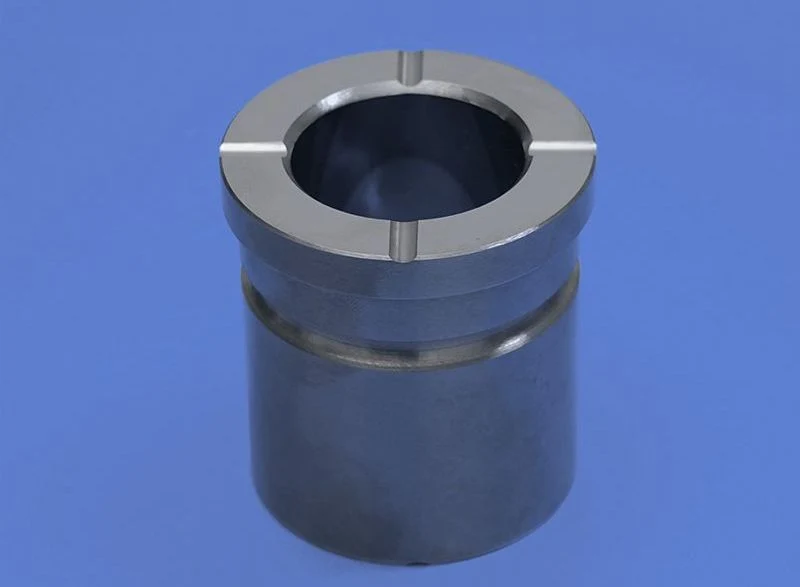

Mechanical Bearing Sleeve Wear Parts Tungsten Carbide Bushings Manufacturer

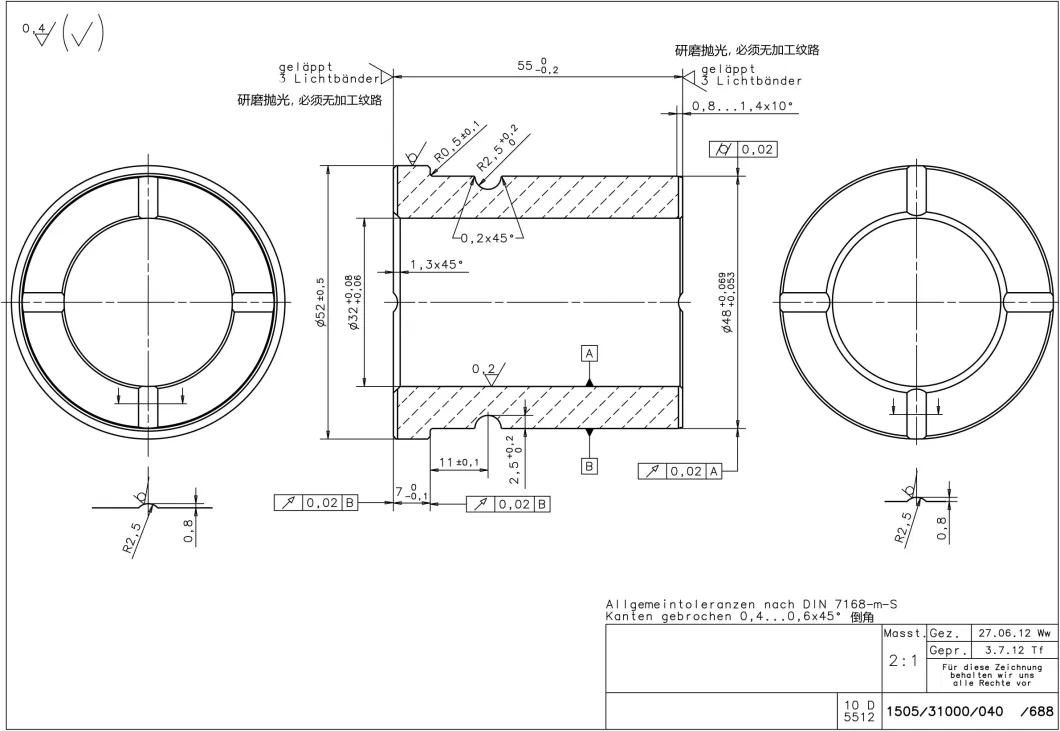

Processing difficulty:

The inner and outer diameters have high precision, the upper and lower cross grooves need to be symmetrical, and the inner hole end face needs to be mirror polished.

Both a bushing and a sleeve bearing, serve a crucial role in various mechanical applications.

Their primary function is to facilitate facilitate linear or rotational movement between two parts. These terms can be used interchangeably.

While simultaneously minimizing friction and dampening vibrations. These bearings possess a commendable load-bearing capacity, making them particularly well-suited for heavy-duty tasks.

They provide several benefits, including minimal friction, a compact design that reduces overall system size, lightweight construction, straightforward installation, and aiding in the reduction of vibration (thus minimizing noise).

Sleeve bearings come in various types and material options. The common flanged type handles axial and radial loads. Cylindrical and thrust washer designs are also available. For higher side loads, a combination of thrust washer and cylindrical bearing works well, while purely radial loads suit a simple cylindrical bearing.

Material choice significantly influences sleeve bearing performance, affecting factors like strength, elasticity, and friction coefficient.

Hard metal, metal ceramic, composites tungsten carbide, cemented carbide, and plastic are common options.

Cast or sintered metal bushings work effectively under hydrodynamic conditions with hard steel shafts.

Because of the high density but small size, tungsten Carbide Processing products are carefully packaged to minimize the risk of damage during transit. Cemented carbide products are packaged in sturdy boxes and sealed to ensure that they reach their destination safely. Packaging materials used include bubble wrap, foam, bubble bags, cardboard, and other appropriate materials provided as necessary.

We use only the highest quality packaging materials to ensure the safe arrival of your products.

We ship our products using reliable and efficient courier services, especially by air.

We mainly offer express shipping for urgent orders like DHL, FedEx, UPS, etc.

Sanxin Carbide Products Features:

| 1 | 100% virgin wolfram carbide materials; |

| 2 | Fine-grain, even ultra fine grain tungsten carbide is available; |

| 3 | Excellent wear, abrasion, corrosion resistance; |

| 4 | High fracture strength and high hardness; |

| 5 | Longer service life; |

| 6 | Varied cemented carbide material grades; |

| 7 | Competitive EXW factory price; |

| 8 | Customization service. |