- Overview

- Product Description

- Company Profile

- FAQ

Basic Info.

Model NO.

DM0213

Surface Processing

Electroplating

Fine Blanking

Open

Process

Separation Process

Industry

Metal Stamping Parts

Tolerances

0.02mm

Customized

Customized

Transport Package

Non Fumigation Wooden Box

Specification

1050*1050*1000

Trademark

dongmo

Origin

Hebei China

HS Code

13119649

Production Capacity

2600 Pieces/Year

Product Description

| Product Details | Company Information | ||

| Product name | Deep drawing water heater mould | Main products | Stamping die Stamping parts |

| Application | Electric water heater | Productive forces | Stamping: 2-3 million pieces/month |

| Material | Steel stainless steel | Mould:60-80sets/month | |

| Standard Parts | MISUMI | Related certificates | ISO9001 |

| Template flatness | +/-0.005mm | Package | According to customer requirements |

| Quantity | 1 set | Application field | Aviation, automobiles, home appliances, medical, hardware, construction, |

We are a company engaged in the production and sales of stamping molds, various metal molds, metal stamping molds, metal stretching molds, and stainless steel stretching molds. We warmly welcome new and old customers to come and guide us, negotiate cooperation, and achieve win-win innovation!

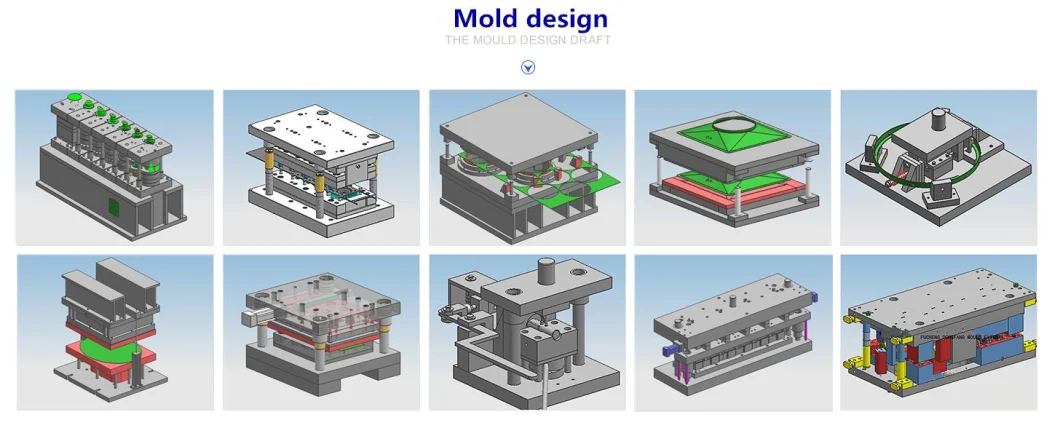

Mold processing equipment: CNC machining center, CNC wire cutting machine tool, CNC electrical discharge molding machine tool, turning, milling, grinding, and other high-precision processing equipment.

Stamping equipment: 630T, 500T, 315T, 200T, 160T, 100T stretch forming hydraulic presses and various large, medium, and small tonnage punches.

Cutting equipment: 2D CNC laser cutting machine, 3D CNC laser cutting machine.

quality assurance

Product development engineers, mold engineers, mold team leaders, and other technical leaders have more than 10 years of work experience

2. From product development to mold testing, professional personnel are responsible for testing to ensure quality

3. Adopt standard parts for mold making, and achieve high-efficiency, precision, and standardization in mold production

4. Mold life: no less than 500000 times

Q: Are you a factory or a trading company?

A: We are a factory, a professional manufacturer of metal stamping molds and metal stamping.

Q: Where is your factory? How can I visit there?

A: Our factory is located in Hengshui City, Hebei Province, China. We warmly welcome customers from home and abroad to visit and patronize us!

Q: What is the material of your mold?

A: Materials include D2, YG15, DC53, SKD11, D2, SKH-9, and SKH-51

Q: What is the maximum pressure in your factory?

A: Our factory has 45T, 60T, 80T, 110T, 160T presses, 100T, 200T, 315T, 400T, 500T, 700T hydraulic presses.

Q: How are the machines in your factory?

A: Our factory has a complete set of processing equipment, including large-scale CNC machining centers, Social EDM processing, imported EDM-HS, radial drilling machines, milling machines, grinding machines, three-dimensional inspection, etc