- Overview

- Product Description

- Applications

Basic Info.

Product Description

Superior Wear Resistance High-Hardness Cemented Carbide Pressure Head

Product Features:

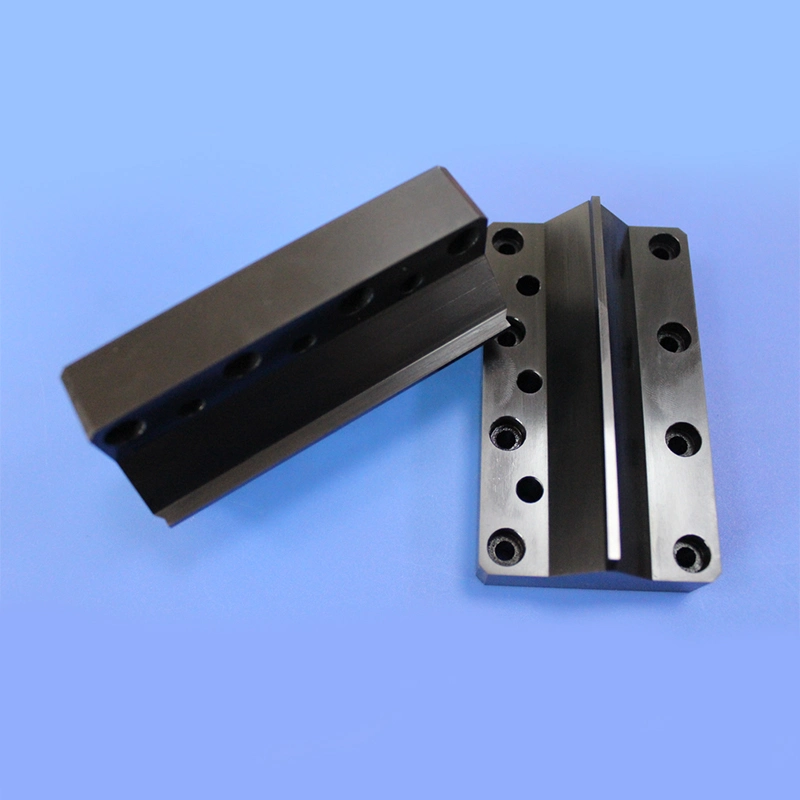

The Tungsten Carbide Pressure Head, serving as a core component in semiconductor packaging, is a high-precision product with accuracy requirements within 0.005. The working surface undergoes a titanium coating process to enhance surface hardness, prolonging the product's lifespan and providing a smoother surface. This innovative design not only reduces friction coefficients but also creates an optimal working condition during operation.

- Semiconductor Packaging Core Component: The Tungsten Carbide Pressure Head is a crucial component in semiconductor packaging, performing essential functions.

- High-Precision Product: The product demands high precision, with positional tolerances controlled within 0.005.

- Titanium-Coated Working Surface: The working surface undergoes a titanium coating process, increasing surface hardness.

- Extended Lifespan: Surface treatment enhances the product's lifespan, ensuring durability.

- Smooth Surface Design: The smooth surface design provides a more seamless working experience.

- Reduced Friction Coefficients: The titanium coating not only enhances hardness but also reduces friction coefficients.

- Optimized Operating Condition: Creates an optimal operating condition, improving efficiency during operation.

Tungsten carbide has many applications in the industrial and jewelry sectors. For example, it is commonly used to form hardened tips and cutting edges for drills, end mills, taps, reamers and other tooling used in material removal processes. Additionally, it can be found in wear parts such as bulldozer blades, excavator teeth, conveyor skip plates, and chute liners, due to its excellent wear resistance.

It is also used to form dies and molds that can withstand high pressures and repetitive use, and to create orthopedic implants like knee and hip prosthetics for its biocompatibility and mechanical strength. Tungsten carbide is even incorporated into drilling tools, oil and gas drilling operations, as well as wind turbine components and exploration equipment.

Aside from industrial uses, tungsten carbide is process into particles and grains for use in coated and bonded abrasives for polishing and grinding applications. Lastly, it is used for decorative components in the jewelry industry for rings, cufflinks, and pendants, thanks to its density and color properties.