- Overview

- Product Description

- Product advantage

- Product Specification

- Packaging

- Reviews From Customers

- Company Profile

- Company Advantage

- FAQ

Basic Info.

Product Description

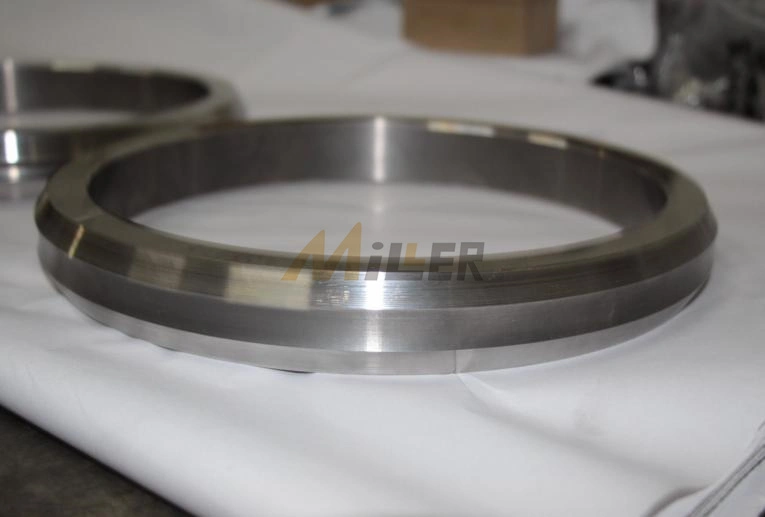

Tungsten carbide rolls is also well known as tungsten carbide cold roll, which is mainly used to produce smooth wire or ribbe wire for the construction reinforcement field.

Benefit from the application of the most modern production methods and the use of the high quality materials, as well as our most experienced employees who manufacture the tungsten carbide rolls, Miller defines a new standard in wire reduction. and increased wire quality through improved surface finishing and rib geometry. When choosing the right carbide rolls for your production needs, it's important to evaluate the load and speed requirements of your manufacturing process. The load refers to the amount of force that the rolls will need to withstand during operation, while the speed refers to the rotational speed of the rolls. Both of these factors can impact the durability and performance of the carbide rolls. Miller can help you determine the load and speed requirements for your specific production needs and recommend the appropriate carbide roll.

Know more, click it

RO/RT/CA TYPE FO TYPE PR TYPE

1. Tungsten carbide rolls can last up to 50 times longer than conventional, hardened tool steel rolls

2. Guaranteed product performance, save more time and work efficiently

3. Solves excess wear problems on any roll section of the mill

4. Fewer changeovers, due to excessive wear on hardened tool steel rolls

5. Holds tighter tolerances on tube and pipe

6. Tungsten carbide rolls should be considered, when high footage/tonnage is required from any one particular size

7. Eliminates pick-up to give tube and pipe a better surface finish

8. Rolls can be solid carbide on smaller mills or carbide-inserted for larger rolls

9. Miller's design expertise can assist in cost justification

10. Drag finished roll surface for the best wire quality

11. Grinding of all profiles and markings

12. Optimum chemical composition and physical properties of carbides

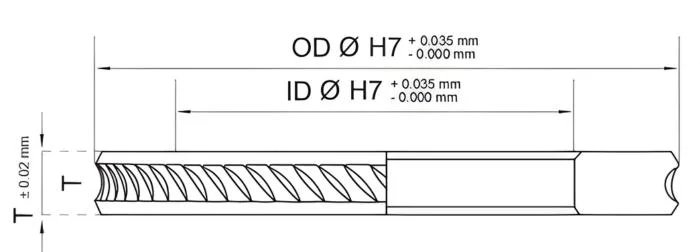

Standard Tungsten Carbide Roll Dimension

| Wire Range φ(mm) | OD φ(mm) | ID φ(mm) | T (mm) |

| Outer Diameter | Inner Diameter | Thickness | |

| 4-8.5 | 125 | 82 | 15 |

| 9-12 | 125 | 82 | 20 |

| 4-8.5 | 140 | 90 | 15 |

| 9-12 | 140 | 90 | 20 |

| 4-8.5 | 150 | 90 | 15 |

| 9-12 | 150 | 90 | 20 |

| 4-8.5 | 160 | 90 | 15 |

| 9-12 | 160 | 90 | 20 |

| 9-12 | 170 | 100 | 20 |

| 9-12 | 220 | 130 | 20 |

φ Inlet (mm) | Oval Reducing | Round Reducing | Forming | Profiling | φ Ribbed Outlet (mm) |

| 4 | RO 0 | RT 0 | FO 0 | PR 3.0 | 3.0 |

| 4.5 | RO 0 | RT 0 | FO 0 | PR 3.5 | 3.5 |

| 5.5 | RO 1 | RT 1 | FO 1 | PR 4.0 | 4 |

| 5.5 | RO 1 | RT 1 | FO 1 | PR 4.5 | 4.5 |

| 6 | RO 2 | RT 2 | FO 1 | PR 5.0 | 5 |

| 7 | RO 2 | RT 2 | FO 1 | PR 5.5 | 5.5 |

| 7.5 | RO 3 | RT 3 | FO 2 | PR 6.0 | 6 |

| 8 | RO 3 | RT 3 | FO 2 | PR 6.5 | 6.5 |

| 8.5 | RO 4 | RT 4 | FO 2 | PR 7.0 | 7 |

| 9 | RO 4 | RT 4 | FO 3 | PR 7.5 | 7.5 |

| 10 | RO 5 | RT 5 | FO 3 | PR 8.0 | 8 |

| 11 | RO 5 | RT 5 | FO 3 | PR 8.5 | 8.5 |

| 11 | RO 5 | RT 5 | FO 3 | PR 9.0 | 9 |

| 12 | RO 6 | RT 6 | RO 5 | PR 9.5 | 9.5 |

| 12 | RO 6 | RT 6 | RO 5 | PR 10.0 | 10 |

| 13 | RO 6 | RT 6 | FO 4 | PR 10.5 | 10.5 |

| 14 | RO 7 | RT 7 | FO 4 | PR 11.0 | 11 |

| 14.0 | RO 7 | RT 7 | FO 4 | PR11.5 | 11.5 |

| 15.0 | RO 7 | RT 7 | FO 4 | PR 12.0 | 12 |

| Type | Application |

| Profiling rolls | Tungsten carbide rolls for with ribs (or indentation) to follow different market standards. |

| Roll Holders | Roll holders are made of steel and hold sizing, forming, reducing and profiling rolls. |

| Descaling Rolls | Descaling rolls are made of tungsten carbide or steel and are used for the mechanical descaling of entry rod in reduction mills. |

| Stress Relieving Rolls | Stress relieving rolls are made of tungsten carbide to improve the mechanical characteristics of the cold rolled wire. |

| Flattening Rolls | These are made of tungsten carbide and are used for metal strips for electrical contacts. |

| Tungsten Carbide Rolls For Strips | Tungsten carbide rolls for strips is to be used in the first roughing stands which use wire rod. |

| Roughing Rolls | Roughing rolls are made of tungsten carbide. |

| Motorized Rolls For Wire Pulling | Different solution of motorized rolls for wire pulling, recommended for critical wire passages. |

| Rolls For Hot Rolling | Rolls made of steel or tungsten carbide insert for hot rolling of copper or aluminium wire rod. |

| Rolls for Car Rims | Steel rolls used to produce car/industrial vehicle rims. |

| Straightening Rolls | These rolls are used to straighten tubes and, according to the dimensions of the tube to be produced, can be made of steel or tungsten carbide. |

| Rolls for Open Profiles | Are made to produce special profiles for various uses such as shelves, sliding guides and decorative applications. |

Miller Carbide is an experienced manufacturer of tungsten carbide customized parts started from 2008. Our products cover carbide grinding jars & mortars, carbide grinding balls, carbide pegs, carbide static & dynamic rings, bead mill disks, carbide stirring rods, carbide static & dynamic jaws, carbide crusher plates, carbide grinding discs, carbide rotors, carbide roll rings, carbide guide rolls, carbide burrs, carbide sleeves & bushings, and other customized wear-resistant components for valve and pumps ect. With years of tungsten carbide engineering and manufacturing experience, we can concentrate our skills to the development of customized products for a wide spread of wear applications in milling & crushing industry.

Unlike other suppliers, Miller operates with three disciplines: Engineering, manufacturing and after sale service support. This means we are able to improve the efficiency of your machine and tools with customized products and direct access to the manufacturer. Miller Carbide works closely with its customers to ensure their requirements are designed efficiently and suitable for application. We can design the components needed from drawings or delivered samples.

We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. We are sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

We Offer You These

| Direct Sales Integrating R&D, production sales and technology | Mold customization Rich molds OEM customization accepted | Adequate equipment grinding/pressing sintering/deep processing | Technical strength 15 years of experience in technical team, research & innovation |

1. How long is your delivery time?

We can arrange the shipment within 3-5 working days upon receipt of your payment for any sintered blanks stocked items. As for the mass production order or the customized products, we will need 10-30 days production leadtime and indicate the delivery time on the Proforma lnvoice.

Contact us now! Get your free quote!