Basic Info.

Model NO.

BAR 01

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Contour Control

Control Method

Semi-Closed Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.03~0.04(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE

Condition

New

OEM

Can Be Customized

Advantage

Shock Precision Boring Bar

Appearance

Polishing Surface

Lead Time

10 Days

Transport Package

Standard Packing

Specification

OEM

Trademark

Sunrise

Origin

Zhuzhou Hunan China

Production Capacity

3 Tons/Month

Packaging & Delivery

Package Size

30.00cm * 20.00cm * 20.00cm

Package Gross Weight

0.400kg

Product Description

Tungsten Carbide Holder Anti-Seismic Milling Cutter Bar with Exchangeble Holder

1.Applications

The anti-vibration tool holder is an important tool accessory in CNC machining. In boring application, large L/D ratios may cause tool deflection and vibrations, influencing the obtained accuracy and surface finish, to complete optimum results for deep hole boring, the tungsten carbide anti vibration tool holder was developed for better machining performance, higher workmanship quality and longer cutting inserts life.

More discount will be offered according to exact quantity.

Welcome to be our agents, OEM is also available.

2.Product Description:

Our Services

1. Strict control in produce for high quality as a manufacture

2. Competitive price with prompt delivery

3. Excellent service with many professional sales and engineers

4. OEM manufacturing supplied ( Including client's own brand )

5. Suitable packing according to customer's requirements

About Us

Zhuzhou Sunrise Hardmetal Tools Co., Limited is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process. All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Sunrise Hardmetal Tools Co., Limited is always insisting on the business idea of "integrity industry, brand business, quality development", and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them. We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

1.Applications

The anti-vibration tool holder is an important tool accessory in CNC machining. In boring application, large L/D ratios may cause tool deflection and vibrations, influencing the obtained accuracy and surface finish, to complete optimum results for deep hole boring, the tungsten carbide anti vibration tool holder was developed for better machining performance, higher workmanship quality and longer cutting inserts life.

More discount will be offered according to exact quantity.

Welcome to be our agents, OEM is also available.

2.Product Description:

We use 100% original raw material, the micro grain tungsten carbide powder and cobalt powder(from German)to make the carbide rod, hardness can be 92.5-94.0(HRA), and T.R.S. is 4200-4800(N/mm2), this carbide rod can ensure the end mills with very strong abrasive resistance and impact strength.

Original raw micro grain material, high hardness and T.R.S.

| 1. Co: 10-12%, WC: 88-90%, Grain size: 0.4μm, Hardness: 92.5-94.0 HRA, T.R.S.: 4200-4800 N/mm2, Density: 14.3-14.8 g/cm3 |

| 2. We got 250T Extruder, 10MPa Overpressure Sintering Furnace-Vacuum these two equipments are very very important for manufacture and high quality carbide rods. |

3.We use our own carbide rod for 90% of cutting tools. |

| 4. We Guarantee high precision and good performance. |

Super coating

Silver or black coating or as your requirement.

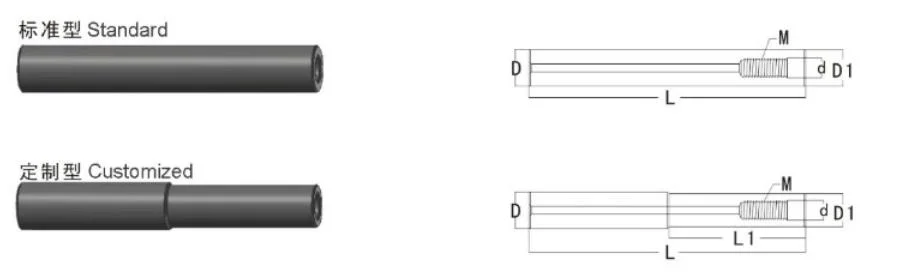

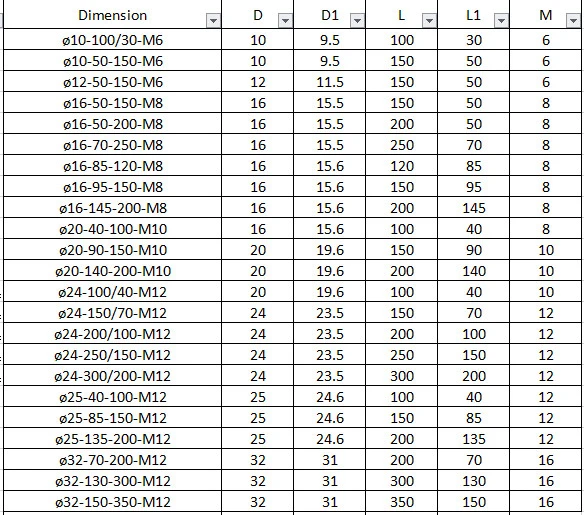

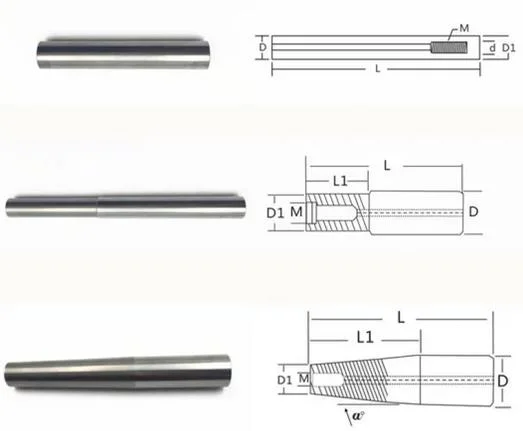

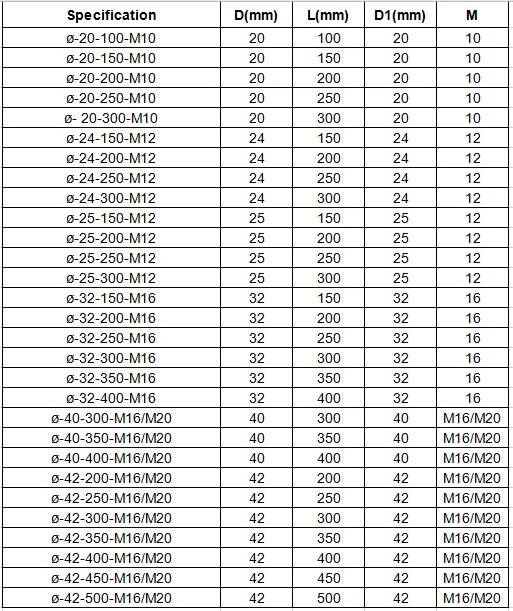

3.Drawing and size

Our Services

1. Strict control in produce for high quality as a manufacture

2. Competitive price with prompt delivery

3. Excellent service with many professional sales and engineers

4. OEM manufacturing supplied ( Including client's own brand )

5. Suitable packing according to customer's requirements

About Us

Zhuzhou Sunrise Hardmetal Tools Co., Limited is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process. All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Sunrise Hardmetal Tools Co., Limited is always insisting on the business idea of "integrity industry, brand business, quality development", and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them. We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.