Basic Info.

Model NO.

Zonco-11497

OEM

Available

Temperature

High Temperature

Transport Package

Carton or Wooden Case. Also Can Be Customized as P

Specification

Customization

Trademark

ZONCO

Origin

China Zhuzhou

HS Code

84819000

Production Capacity

800-1000PCS Per Month

Product Description

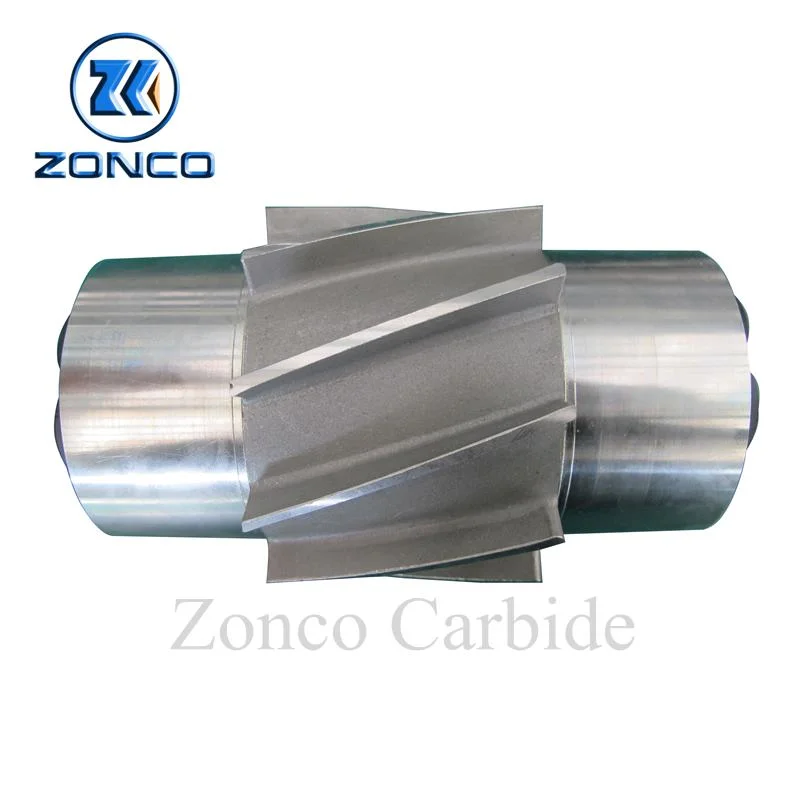

Product Description Tungsten Carbide Material Stator for Aps Advanced Mwd Systems in Oil and Gas industry

Product Description

Carbide rods, that is, cemented carbide rods, also known as tungsten rods, are simply tungsten rods or carbide rods. Cemented carbide is a composite material composed of a refractory metal compound (hard phase) and a binder metal (bonded phase) produced by powder metallurgy.

Tungsten carbide double helix holes rod is a kind of rod with double helix holes, the general helix angle are 15°, 40°, 45°and 60°. Tungsten carbide rods with two holes are mainly used for PCB micro drills, electrode rod of optical communications industry, drill bits of machining industry, drill shank, wear precision parts and so on.

Features:

High Transverse Rupture strength

Ultrafine/Submicron Grain Size

High Hardness

High Density

High hardness and abrasion resistance, suitable for wear hinging and die locator pins, cutting and drilling tools, and high wear applications with minimal shock conditions

Dimensions and tolerances of tungsten carbide rods with two helical holes for references:

Tungsten Carbide Material Stator for Aps Advanced Mwd Systems in Oil and Gas industry

Quick detail

| Particle:Sub-fine Grain Size | Dimentions: OD6.0X330 | Surface: Ground or Blank |

| Grade: K10, K20, K30, C2, C6, YF06 | Virgin material:100% | Trade term: CIF,EXW,FOB |

| Delivery Time: 3-20 days | OEM Service: Acceptable | Trial order: Acceptable |

Product Description

Carbide rods, that is, cemented carbide rods, also known as tungsten rods, are simply tungsten rods or carbide rods. Cemented carbide is a composite material composed of a refractory metal compound (hard phase) and a binder metal (bonded phase) produced by powder metallurgy.

Tungsten carbide double helix holes rod is a kind of rod with double helix holes, the general helix angle are 15°, 40°, 45°and 60°. Tungsten carbide rods with two holes are mainly used for PCB micro drills, electrode rod of optical communications industry, drill bits of machining industry, drill shank, wear precision parts and so on.

Features:

High Transverse Rupture strength

Ultrafine/Submicron Grain Size

High Hardness

High Density

High hardness and abrasion resistance, suitable for wear hinging and die locator pins, cutting and drilling tools, and high wear applications with minimal shock conditions

Dimensions and tolerances of tungsten carbide rods with two helical holes for references:

Common Alloy Grades, Ghysical Mechanical Properties And Recommended Application | |||||||

| Grade | WC% | Co/Ni % | Physical and mechanical properties | Grain size (μm) | Recommended application | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | |||||

| ZG01 | 100 | 0 | 15.3-15.5 | 1200 | 95.5 | 0.3 | Ultra-high hardness, high wear resistance, anti-corrosion, with certain anti-destructive ability |

| ZG04X | 96 | 4 | 15.0-15.2 | 1600 | 92.8 | 0.8-1.0 | Suitable for drawing die, non-ferrous metal wire drawing and wear-resistant parts |

| ZG06 | 94 | 6 | 14.8-15.1 | 2500 | 90.0 | 1.2 | Good abrasion resistance, good compression resistance, suitable for wear-resistant parts that resist abrasion and high pressure. |

| ZG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 1.0 | Superio wear resistance,good comprehensive properties,suitable for making non-standard structure components with higher wear resistance. |

| ZG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 | |

| ZG08 | 92 | 8 | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for general wear parts, molds, general tools, etc. |

| ZG10.2 | 90 | 10 | 14.3-14.6 | 3800 | 91.7 | 0.7 | Good general performance, suitable for casing and oil nozzle products |

| ZG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 | Anti-wear, anti-erosion, good comprehensive mechanical strength, suitable for wear-resistant parts in the petroleum, chemical and mechanical industries. |

| ZG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 | Anti-erosion, good comprehensive mechanical strength, suitable for impact-resistant wear-resistant parts, molds, and roller rings. |

| ZG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 | |

| ZG15X | 85 | 15 | 13.8-14.2 | 4500 | 89.0 | 0.7 | Excellent wear resistance and toughness,it is suitable for making integral stamping dies, anti-vibration toolholders, etc. |

| ZG20 | 80 | 20 | 13.4-13.8 | 3100 | 85.0 | 1.0 | Excellent wear resistance and toughness |

| ZN06 | 94 | 6 | 14.5-14.9 | 2000 | 90.0 | 1.2 | Non-magnetic alloy, suitable for sealing ring, non-magnetic wear-resistant parts and corrosion-resistant parts. |

| ZN09 | 91 | 9 | 14.3-14.6 | 2300 | 89.0 | 1.2-1.6 | |

| ZN11 | 89 | 11 | 14.0-14.3 | 2600 | 88.0 | 1.2 | |