- Overview

- Product Description

- Product Parameters

- Main features

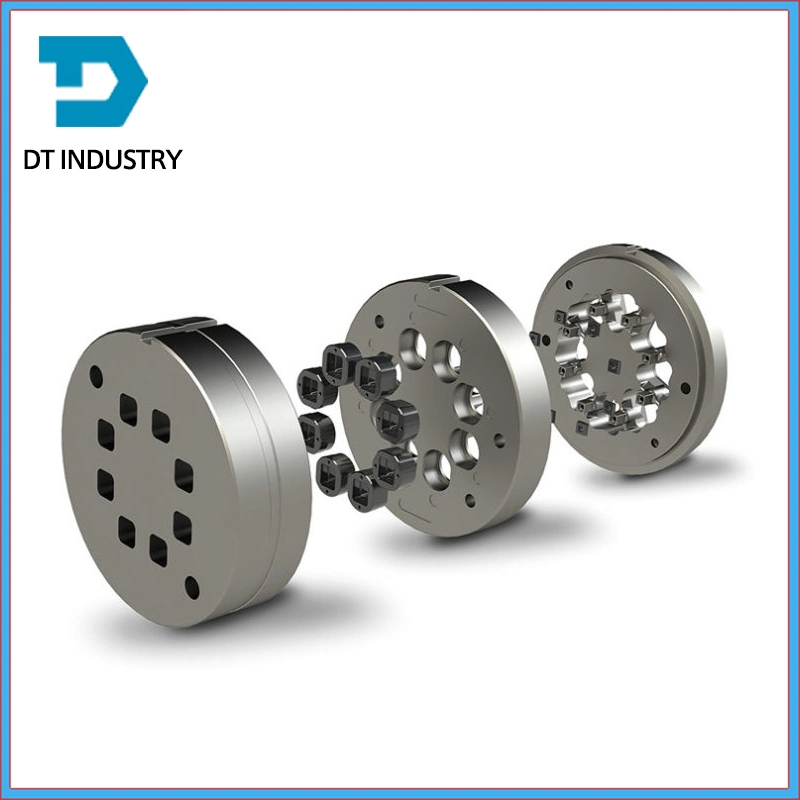

- Related products

- Our Advantages

- Company Profile

- You may like

Basic Info.

Product Description

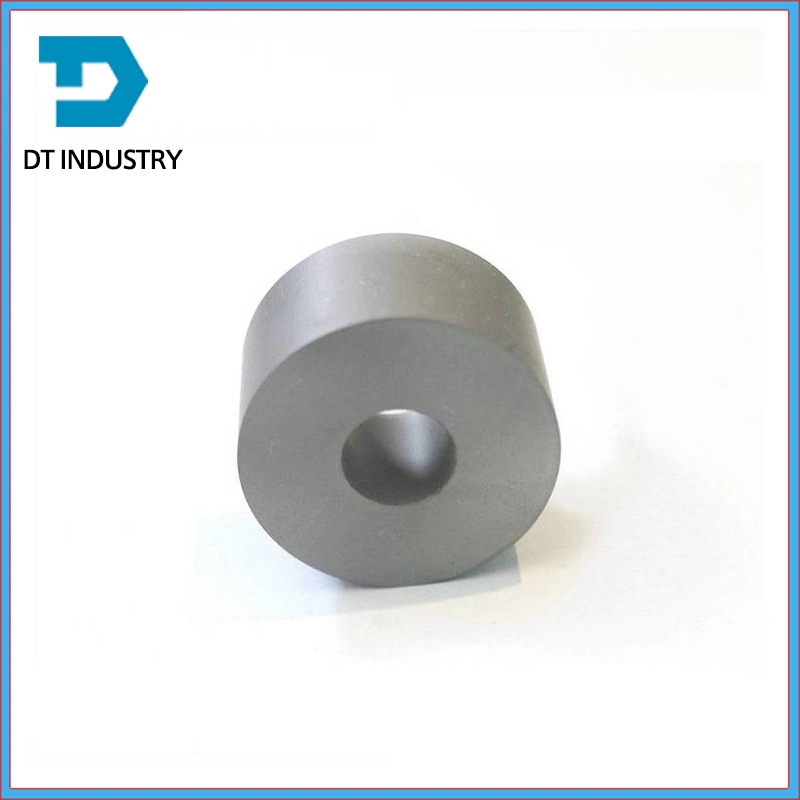

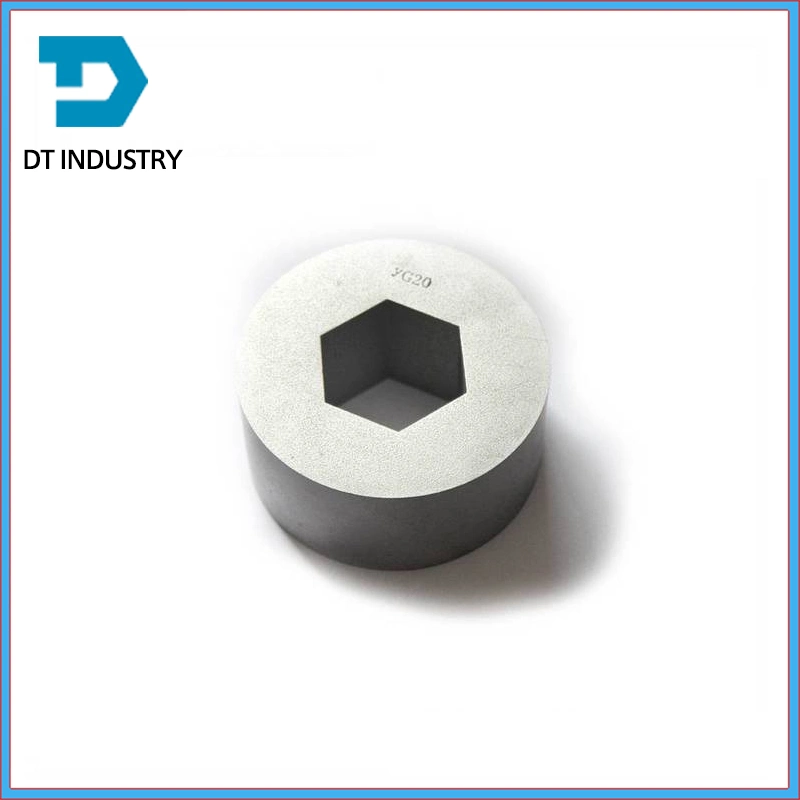

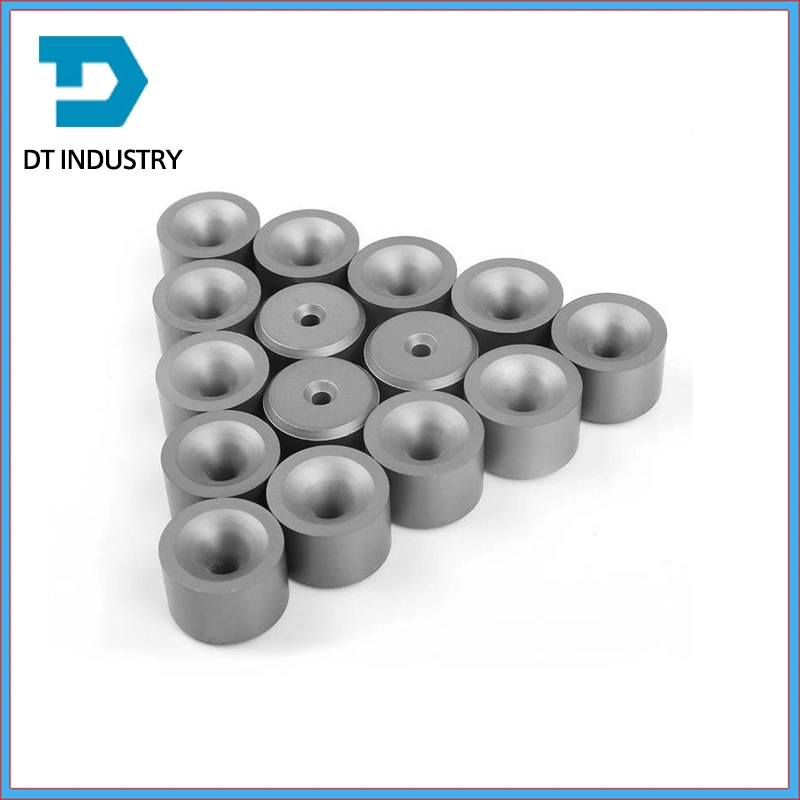

carbide mechanical seal ring uses tungsten carbide powder as raw material, adding cobalt powder or nickel powder as a binder, by a certain molded into a ring, and sintering in a vacuum furnace or hydrogen reduction furnace. As the most widely used mechanical seal products, cemented carbide seals have been widely used in the petrochemical industry and many other sealing industries because of their high hardness and good corrosion resistance.

Product information:

1. Wear resistance, corrosion resistance and stability characteristics, protective bushing, anti-wear, mute block, harmful substances separated from bearings, sleeve protector.

2. High precision, various sizes and shapes.

3. H6 tolerance, fine polishing, mirror. The conventional markings of cemented carbide seals produced by the company are as follows: Mechanical seals are used to seal the gap between the rotating shaft and the fixed housing in equipment such as pumps and mixers so that liquids do not leak out of the gap.

------WELCOME TO CUSTOMIZE-----

| Model number | Binding agent (Wt%) | Density (G / Cm 3) | Hardness (HRA) | TRS (> N /Mm²) |

| YG6 | 6 | 14.8 | 90.0 | 1520 |

| YG6X | 6 | 14.9 | 91.0 | 1450 |

| YG6A | 6 | 14.9 | 92.0 | 1540 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| YG12 | 12 | 14.2 | 88.0 | 1810 |

| YG15 | 15 | 14.0 | 87.0 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |

| YG25 | 25 | 12.1 | 84.0 | 2550 |

The cemented carbide seals produced by the company have the following characteristics:

Product information:

1. Wear resistance, corrosion resistance and stability characteristics, protective bushing, anti-wear, mute block, harmful substances separated from bearings, sleeve protector.

2. High precision, various sizes and shapes.

3. H6 tolerance, fine polishing, mirror. The conventional markings of cemented carbide seals produced by the company are as follows: Mechanical seals are used to seal the gap between the rotating shaft and the fixed housing in equipment such as pumps and mixers so that liquids do not leak out of the gap.

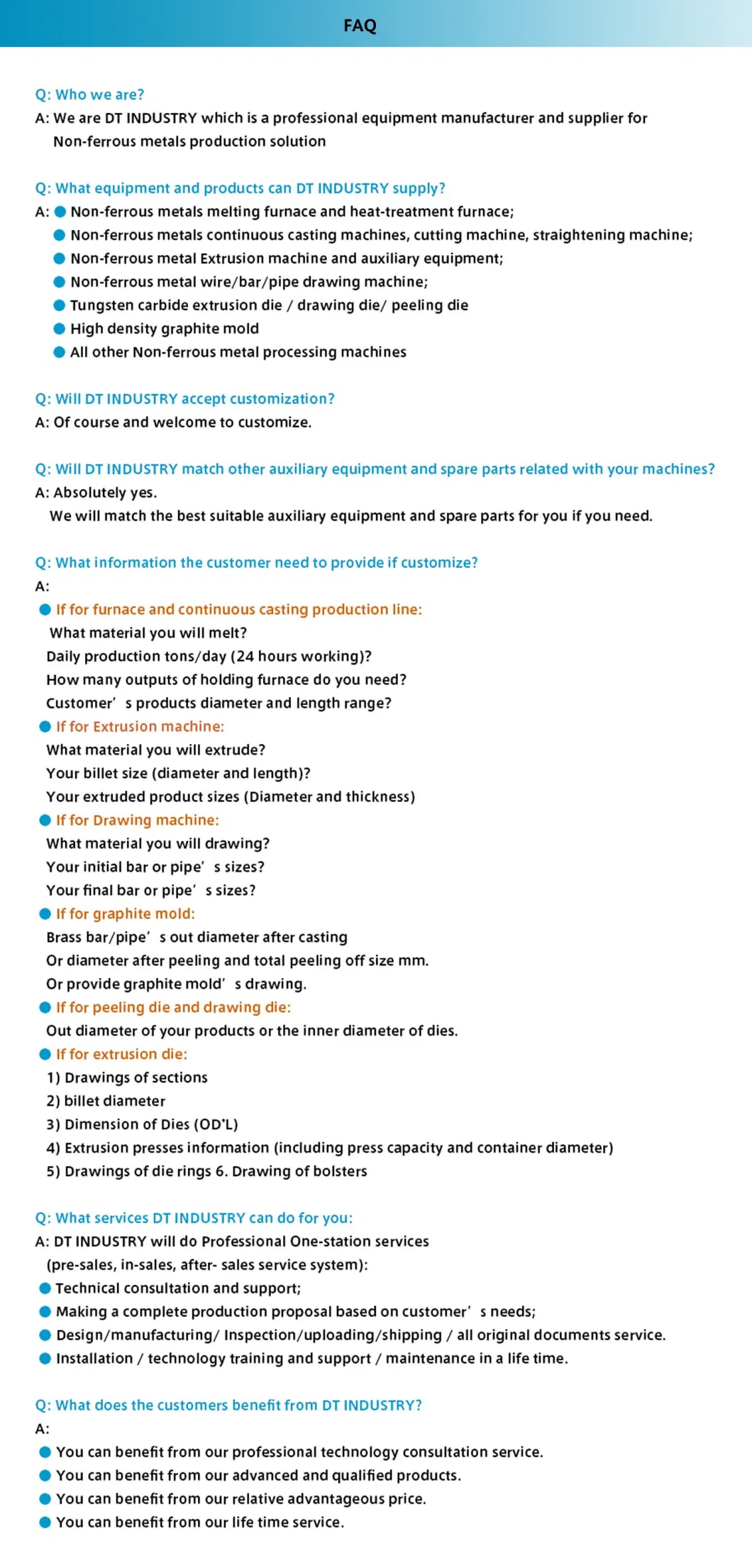

Inspecting, packing, uploading and shipping service;

Offering all related auxiliary machines, spare parts and consumable tools;

Installing and adjusting machines on site and technology training your labors for operation;

Trial production on site till everything is going well;

On-site technology support if customer needs.

24 hours service online before sales and after sales.

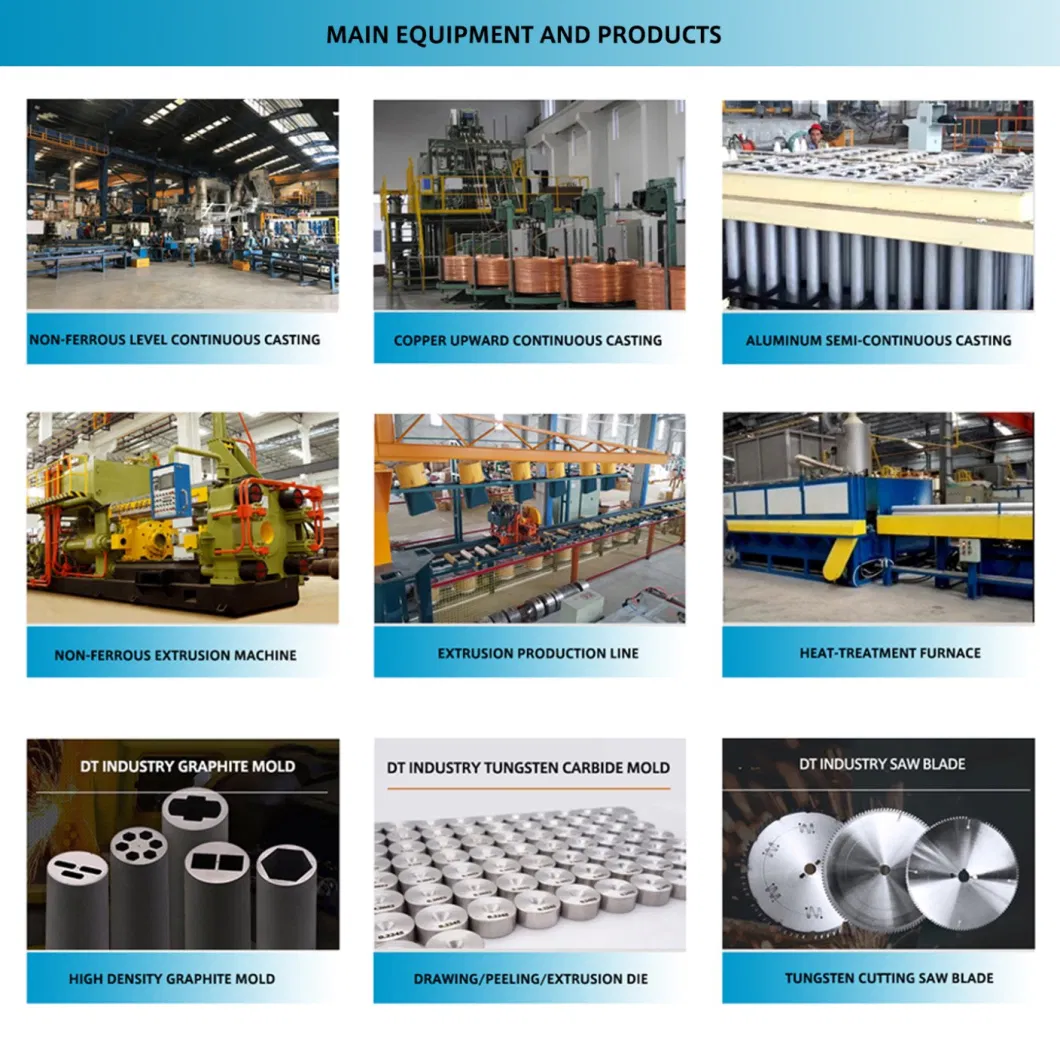

The main machines are electric melting furnace, holding furnace, continuous casting machine, cutting machine, peeling machine, chamfering machine, drawing machine and, straightening machine. And rolling equipment for steel and brass and copper strip.

Also we are supplying Graphite products for non-ferrous continuous casting production line and tungsten steel mold for extrusion and drawing and peeling production line.

We have a professional and passionate service team, including research and development department, technology support department and international after sales service department.

Our advantages: Qualified Machines; Professional technology, Efficient Service, Worry-free Guarantee.

Our Values: Products as the fundamental, Customers as the center, Create a win-win situation.