Basic Info.

Name

Tungsten Carbide Shaft Sleeve for Pump or Bearing

Used

Used for Water Pump, Oil Pump

Surface

Ground, and Unground

Advantage

Superior Wear-Resistance and Impact Toughness

Shape

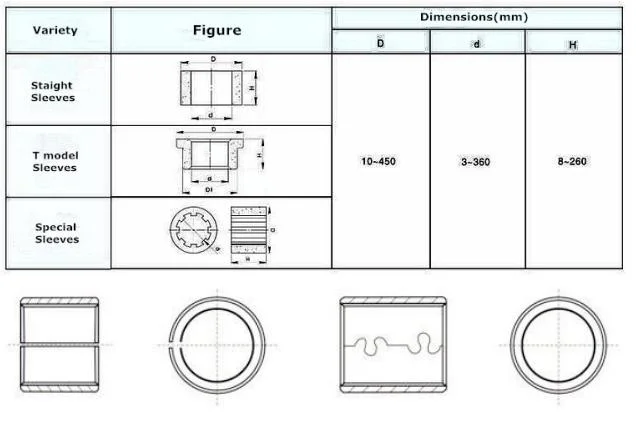

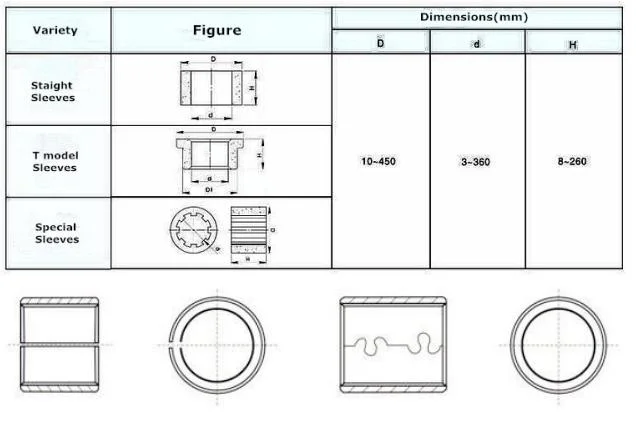

Sleeve, Flanged, Spacer

Size

OEM Accepted

Chemical Composition

Wc and Co

Production Feat

Wrapping

Feature

Self Lubricating, Maintenance Free, Long Life

Surface Treatmen

Cooper Plating, Tin Plating, Zinc P

Transport Package

Parper Box

Trademark

Lihua

Origin

Zhuzhou

HS Code

8413910000

Production Capacity

5000 Piece Per Month

Product Description

Tungsten Carbide Shaft Sleeve for Pump or Bearing

Features

1.Abrasive resistant, corrosion free, good compression property, high wear-resistant bushing, heat resistance, low maintenance;

2.The hardness is 10 times of gold, 5 times of tool steel, 4 times of titanium, oil resistance, separate the harmful medium;

3.No shape change, high bending strength when temparature is above 1000 ° C or below 500 °C, long service life, the maximum height can reach 270mm

Applications

1. Tungsten Carbide Bearing Bushings have the characters of high wear resistance, high corrosion resistance and good compressive properties.

2. It's widely used in petrochemical industries and other industries which call for high properties of the bearing bushings or shaft sleeves.

3. Tungsten carbide bush is the basic material among the frictional materials. They are widely use as the basic components for sealing. And the bushings are widely adopted in petrochemical industry due to its excellent performances such as wear ability, anti corrosion.

Grade informations for sintered carbide shaft sleeve

| Grade | Binder (Wt%) | Density (g/cm3) | Hardness (HRA) | TRS ( N/mm2) |

| YG6 | 6 | 14.8 | 90.0 | 1520 |

| YG6X | 6 | 14.9 | 91.0 | 1450 |

| YG6A | 6 | 14.9 | 92.0 | 1540 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| YG12 | 12 | 14.2 | 88.0 | 1810 |

| YG15 | 15 | 14.0 | 87.0 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |

| YG25 | 25 | 12.1 | 84.0 | 2550 |

Details Images

Thickness: 8-30mm

Diameter: 25-500mm

Length: 100-2000mm

Appearance: silver grey metal luster

Density: Purity: W ≥ 99.95%

Quality standard: GB/T 4187-1984 (tungsten rod) ASTM F288-90

Supply state: sintering or processing

Dimension: Φ (25-500)mm × L(100-1000)m

We can offer a variety of solutions according to clients' application requirement.

These customized sizes carbide sleeves, we produced for one of our Russian customers. Thickness: 8-30mm

Diameter: 25-500mm

Length: 100-2000mm

Appearance: silver grey metal luster

Density: Purity: W ≥ 99.95%

Quality standard: GB/T 4187-1984 (tungsten rod) ASTM F288-90

Supply state: sintering or processing

Dimension: Φ (25-500)mm × L(100-1000)m

We can offer a variety of solutions according to clients' application requirement.

01.01.12.004-01; 01.01.00.005; 01.01.12.002;

350.13.00.004; 350.13.00.006; 350.14.00.002;

650.15.00.002

If you want to know more details, please contact us directly.

Company Information

About Lihua Cemented Carbide

Established in 1996, specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products.

Our products sold to worldwide. We have built a long term business relationship with the customers from Italy, Portugal, Germany, Turkey, USA, Mexico, Russia, India, Australia and so on.

Main Products

Our Main products include : Carbide Screwed Boring Bar, Plates, Rods, Sticks, Bushings, TP nozzles, 3D Printer Nozzles, Saw Blades, End Mills & Drill Bits, CNC inserts, Value Seats, Rotary Burrs, wheel cutters, Grits, Customized cutter: Woodworking tool cutter, V-cutter, mining tool, Any customized carbide products are acceptable.

Month capacity of 15 Tons

We have sophisticated equipment, such as Sintering Furnace, Automatic suppress Machine, Manual Hydraulic Suppress Machine, Ball Mill Machine, Drying Machine, Mixing Machine etc, Our production capacity up to 15 Tons per month. Customized is welcome, customized sample can be ready in 3-5 days and 1 day can deliver for stocks.

Strictly QC

We have a professional QC team follow to the System of ISO9001:2008, Covering the Raw Materials Incoming, Production Processes, Finished Products and Packaging to ensure high quality products output.

If you are interested in our product, please feel free to contact us.

Contact:

Foreign Sales Representative: Lumina

Website: http://lihuacarbide.en.made-in-china.com

Factory Address:B-11 Gaoke E-commerce Industrial Park, Xinma South Road, Tianyuan zone, Zhuzhou city 412000, Hunan province, China