Basic Info.

Product Description

1. We are real factory in Zhuzhou: competitive price

2. we adopt advance production and testing equipment : good quality

3. We have professional technicians: providing professional solution and suggestion

4.100% virgin material

5.100%inspection before shipment

6. Fast response and delivery

| Grade | Equal to ISO Category Number | Performance | Performance&application recommended | ||

| Density G/Cm 3 | Bend Strength N/mm 2 | Hardness HRA | |||

| YG3 | K01 | 14.9-15.3 | ≥1180 | ≥90.5 | Sand-blasting nozzles qualified for fine turning and half-fine turning when cast iron, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively. Can make wire drawing of steel and non-ferrous metal. Also qualified for sand-blasting nozzles. |

| YG3X | K01 | 15.1-15.4 | ≥1300 | ≥91.5 | |

| YK05 | 14.95 | 2500 | 90.5 | Mostly used as the buttons of small and bits medium sized percussion | |

| YG8C | 14.8 | 2400 | 88.5 | and as the inserts of rotary prospecting bits to cut soft and | |

| medium hard formations. | |||||

| YG6 | 14.95 | 1900 | 90.5 | For coring crowns,electric coal drill bits, coal cutting picks,oil | |

| cone bits and scraping knife bits,used in coal geological prospecting, | |||||

| mining and oil well boring. | |||||

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG8 | K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YG10X | 14.5 | 2400 | 91.5 | Fine grain alloy, good wear resistance,Used for processing hard | |

| wood, veneer board,PCB,PVC and metals. | |||||

| YG11 | 14.4 | 2600 | 88.5 | Forming or stamping dies for metal powders and nonmental powders. | |

| YG11C | K40 | 14.4 | 2700 | 86.5 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium |

| hard, hard and very hard formations. | |||||

| YG15 | K40 | 14 | 2800 | 87.5 | For fabricating drawing dies of steel tubesand rods under high |

| compressibility ratio;punching,stamping,forging tools under large stress. | |||||

| YG15C | 14 | 3000 | 85.5 | For oil cone dril bits, for medium soft and medium-hard rocks. | |

| YG16C | 13.9 | 2900 | 85.5 | Impact resistance, hot&forging dies etc. | |

| YGH40 | 13.5-13.9 | ≥2450 | ≥83.0 | Mainly for making hot dies. | |

| YG20 | 13.5 | 3200 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical | |

| instruments, battery jars,small sized steel balls,screws,screw caps. | |||||

| YG18C | 13.7 | 3100 | 84.5 | Impact resistance forging dies,hot-press forging dies and rollers. | |

| YG20C | 13.5 | 3300 | 83.5 | Dies for wear resistant or impact resistant application. | |

| YG22C | 13.3 | 3500 | 83 | Nut forming dies and high impact resistance forging dies. | |

| YG25C | 13.1 | 3600 | 82.5 | Stainless bolt header dies and rollers. | |

| YT15 | P10 | 11.1-11.6 | ≥1180 | ≥91.0 | Qualified for rough machining, semi-finish machining and finish machining during consecutive machining of carbon steel and alloy steel. |

| YT14 | P20 | 11.2-11.8 | ≥1270 | ≥90.5 | Qualified for rough machining for rough face of carbon steel and alloy steel, half process during discontinuity cutting. |

| YT5 | P30 | 12.5-13.2 | ≥1430 | ≥89.5 | Qualified for rough machining for rough face of carbon steel and alloy steel and discontinuity cutting. |

Applications of tungsten carbide products

Applications of tungsten carbide productsTungsten carbide rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel-based alloy,

titanium alloy, and nonferrous metals.

Tungsten carbide strips widely known as one kind of carbide cutting tools, it's available for different grinding geometric

parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional, carbide inserts semi-automatic lathe, automatic lathe and planning machine to work grooves and operate cutting.

Tungsten carbide ball and seat:Subsurface pump/Oilfield Tubing pump/Insert pump, sealing, it is widely used in petroleum industry and other anti-corrosion machine parts.

We can produce any type and size carbide plate, tile , teeth for the agriculture tool parts. Application for Side band , Rumpstad, Tine Fit , Cultivator , Tillages. Shredder Knives etc.

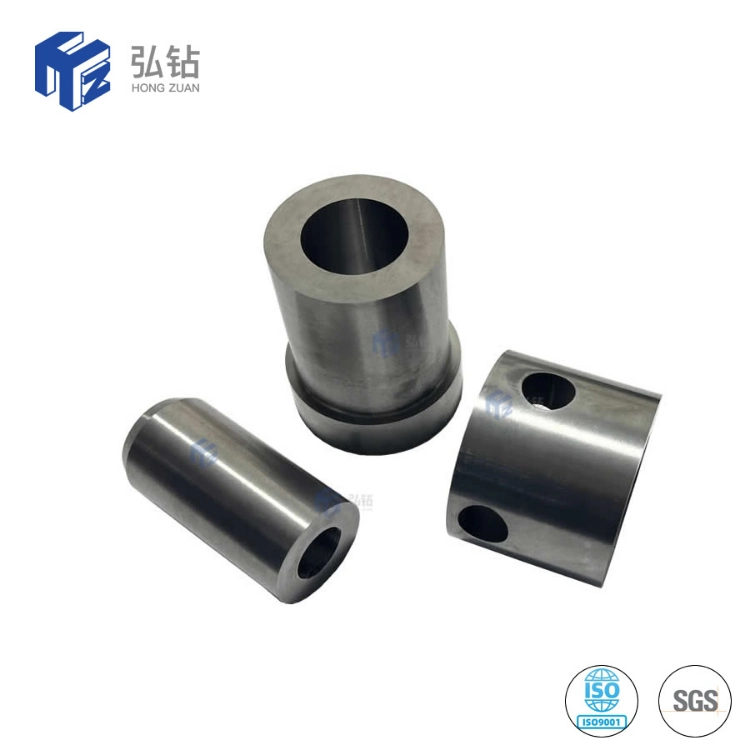

Tungsten carbide moulds

1. Used for making high temperature parts, wear parts, anti-shielding parts and corrosion-resistant parts.

2. Used in making hardware and standard stamping moulds.

3. Applicable for electronic industry, motor rotor, stator, LED lead frame, EI silicon sheet and so on.

4. Used for producing drawn mold, wear-resistant parts, stamping parts and automatic press with punch.

5. Used for stamping die, extrusion die, stamping molds.

6. Drawing many kinds of steel wire, aluminum wire, high carbon, MS wire etc

Tungsten carbide button is mainly used for manufacturing taper button bits, DTH button bits, thread button bits and mining picks.

Our factory offer a wide range of Brazing tungsten carbide soldering insert for both wood and metal cutting

Company Profile

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in the hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications. Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes,Finished Products and Packaging to ensure high quality products output.

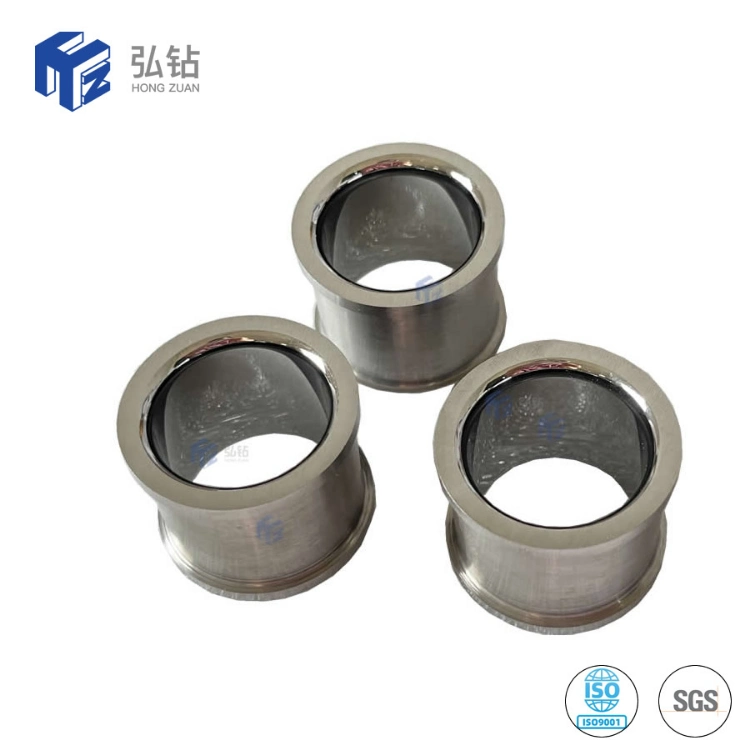

We mainly produce Tungsten Carbide Ball and Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles,

HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars, Rod, Strips, PDC substrate, Weld on teeth,

Bushings, Wire Drawing Dies, Heading Dies, Seal Ring, Nozzles, and other customized carbide products.

Product packaging

FAQ

Q1 : Are you Factory or trading company ?We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on