Basic Info.

Product Description

Non-Magnetic Carbide belt cleaners, strip, plate from china

1. Manufactured from high grade tungsten tip thickness and stainless steel.

2. Hip sintered, high hardness, high wear resistance

3. Various sizes and full types available

4. Reasonable price,Fast delivery time

5. OEM Customized(small order accepted,professional technical support)

6.ISO 9001 Certification

More details of specific type, please inform us!

Product Description

1. Higher Cleaning Efficiency:

The obvious feature of Carbide Conveyor Belt Scraper is lower lifetime cost, becaue of the carbide durability. Brazing makes the carbide strips more compatible with mechanically-spliced belts as well. High bonding strength, high wear resistance, durable.

2. More Cost-effective

Considering lifetime cost, although the initial cost is higher, Carbide conveyor belt scraper durability and lower required maintenance make up the cost difference over the life of the belt scraper, which becomes important when you think about overall costs.

Product advantages:

Can be used for toughest working environment, and highest cleaning efficiency is a key attribute.

Can be used for highly abrasive materials, and extremely wear-resistant is the key point.

Can reduce maintenance times, reducing unacceptable wear rates, highly improving working efficinece.

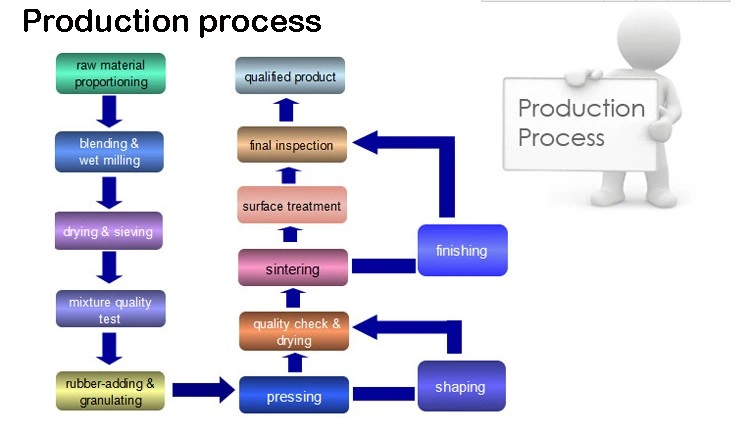

Production process

Carbide production: Use Chinese best 100% vigin material to guarantee the high wear resistance, use TPA presser and HIP sintering to maintan stable quality.

Use special brazing method for the high bonding strenght to avoid carbide blade dislodging.

Using CNC machining center and grinder for the post-processing, ensuring the precision size.

Different sizes

Company Information

FAQ

Q: Are you trading company or manufacturer ?

A: Yes,We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<1000USD, 100% in advance. Payment>1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us!