- Overview

- Product Description

- Detailed Photos

- Packaging & Shipping

- FACTORY PRODUCING EUIPMENT

- CERTIFICATE

- FAQ

- Contact

Basic Info.

Product Description

Proffessional Manufacturer tungsten carbide items since 1989

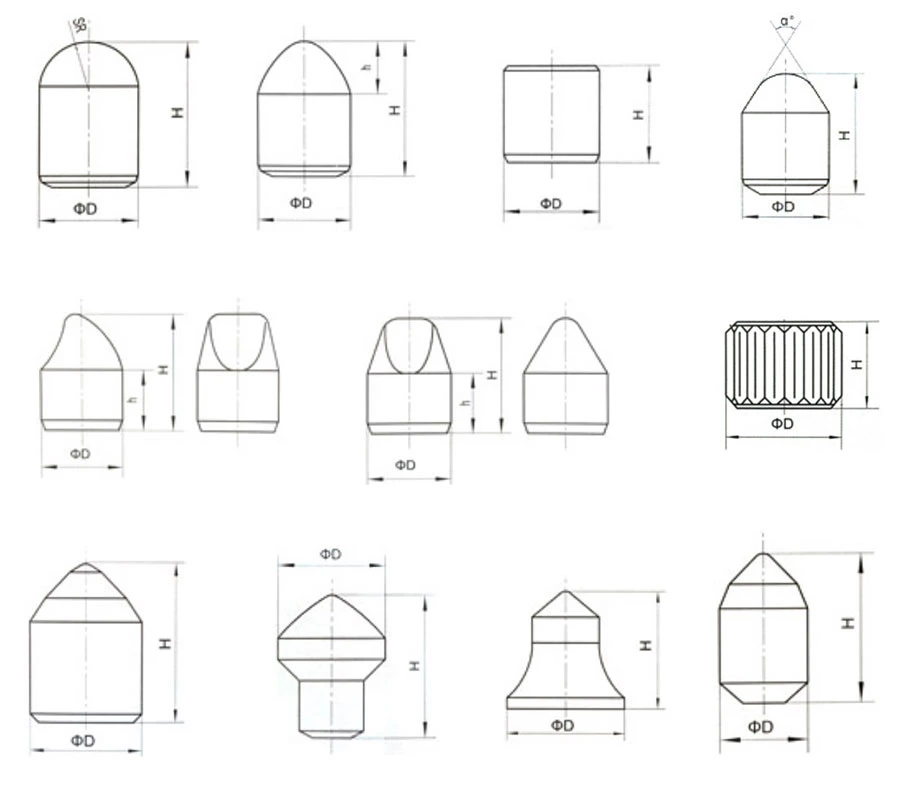

2.Tungsten carbide button are widely applied for rock tools, mining tools for use in quarrying,

mining, tunneling, and civil constructions.

3. The tapered drill bits with diameter32mm to 36mm are widely used in mining and quarrying, with the advantages of higher driving efficiency, long service life, better powder exhausting and easier bit back, which combine well anti-wear and anti-impact carbide butttons and high-performance steel together.

4. 32mm 7 button bits are widely used in stone quarrying, they are made from proprietary grade of cemented carbide, that makes excellent performance in hand held rock drilling machines.

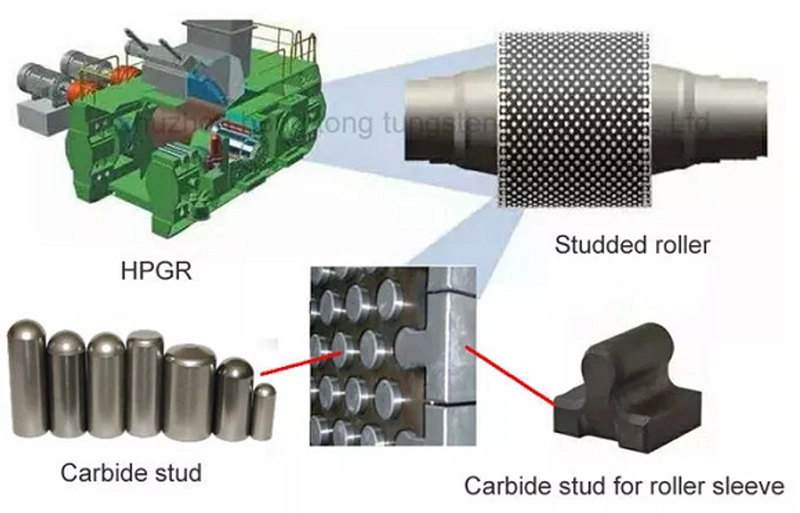

5.High Pressure Grinding Roller is an energy-efficient crushing equipment of new technologies. High performance of carbide stud extends the life of High-Pressure-Grinding-Roller.

6. Suited for abrasive to very abrasive drilling conditions

| Product name | Tungsten carbide buttons for mining and oil-field drilling |

| Material | WC+CO tungsten carbide |

| Grade | |

| Certification | ISO9001:2015 |

| Tolerance | Customer's request |

| Usage | petroleum drilling and snow removal |

| Size | Customer's request/accept customized |

| If you have others request,Welcome Contact us | |

| Grade | Cobalt Content% | Physical And Mechanical Properties | Application Fields | |||

Density(g/cm3) ±0.1 | Hardness(HRA) ±0.5 | TRS(Mpa)≥ | Grain Size(um) | |||

| RK06SC | 6 | 14.88 | 87.5 | 2200 | 4.0 | Suitable for deep milling-planing of asphalt pavement and cold-recycling processing on pavement |

| RK06SA | 6 | 14.90 | 88.0 | 2400 | 3.2 | Suitable for cold milling-planing of asphalt pavement and milling-planing of cement pavement |

| YG11C | 11 | 14.40 | 87.0 | 2650 | 3.2 | 1. Suitable for making rotary digging and drilling tools; suitable for construction of medium-hard rock and soil layer of certain thickness in sand, cohesive soil and silty soil. 2. Suitable for cutting tips of coal cutter and mining the coal layer with little coal gangue and interlayer of certain thickness. 3. Chisel inserts are suitable for drilling hard and extremely hard rock layers. |

| RK08SC | 8 | 14.68 | 86.5 | 2300 | 4.0 | 1. Suitable for cutting tips of rotary excavation and boring and coal seam mining, soft rock construction; 2. Suitable for cutting tips of roadway boring, soft rock interlayer; 3. Suitable for groove excavation tools, used for excavation of road with a small amount of stones. |

| RK08TC | 8 | 14.70 | 85.8 | 2200 | 6.0 | 1. Suitable for coal mining in various working conditions, roadway boring and tunnel boring in complex rock layers; 2. Suitable for rotary excavation in bad rock formation conditions. |

| RK10SC | 10 | 14.45 | 85.8 | 2400 | 4.0 | 1.Suitable for making rotary excavation and drilling tools; suitable for construction of soil layers with small amount of stones such as sand, clay and silty soil. 2.Suitable for cutting tips of coal cutter, mining the coal seams with many interlayer rock conditions; 3.Suitable for cutting tips of roadway boring, medium-soft and hard rock interlayer containing a small number of large rocks; 4.Suitable for complex road trench excavation tools, used for excavation of the road containing many stones. |

Q: Are you trading company or manufacturer ?

A: We are a Group company , manufacturer of tungsten carbide since 1989 and

professinal own export company,and we We can supply 20 tons tungsten carbide product per month. We can provide customized carbide products as per your requirements.

Q: How long is your delivery time?

A: Generally,it will take 7 to 15 days after order confirm.The specific delivery time depends on the specific product and the quantity you needed.

Q: Do you provide samples? iIs it free or charged?

A:Yes, we can offer a sample for free charge but the freight is at customers' cost.

Q. Do you test all your goods before delivery?

A: Yes, we will do 100% test on our cemented carbide products before delivery.

Dear Customer

when you send inquiryk please inform us of the following information:

1. Grade

2. Type/Dimension/Clear Drawing

3. Available tolerance

4. Order quantity

5. Blanks or finished products

6. If you have any special requirements of the products, pls send us in advance. We will satisfy you as much as we can.

Contact Us

Pls feel free to contact us you have any requirments, Proffesional sales is available!

Offer OEM/ODM Service About The Shape,Size,Specifications

Contact us for Lowest Price And Details

Sophia Sun