Basic Info.

Model NO.

T039

Material

Tungsten Carbide Steel

Application

Metal Cutting Machine, Metal Processing Machinery Parts, Metal Punching Machine

Heat-Treat Process

Vacuum Nitrided Hot Treatment Salt Bath Heat-Treat

Surface Treatment

Customized

Lead Time

3-20 Days

Coaxiality

±0.002mm

Roundness

±0.001mm

Arc Tolerance

±0.015mm

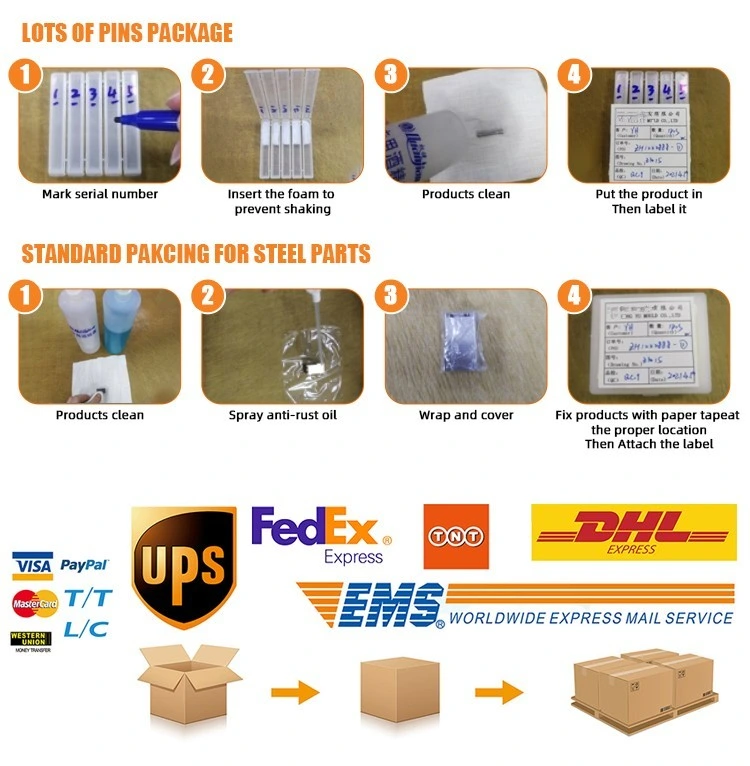

Transport Package

PP Bag Foam Inside, Carton/Wood Case Outside

Specification

L35cm*W20cm*H25cm

Trademark

BG

Origin

Dongguan

HS Code

8209003000

Production Capacity

5000000/Year

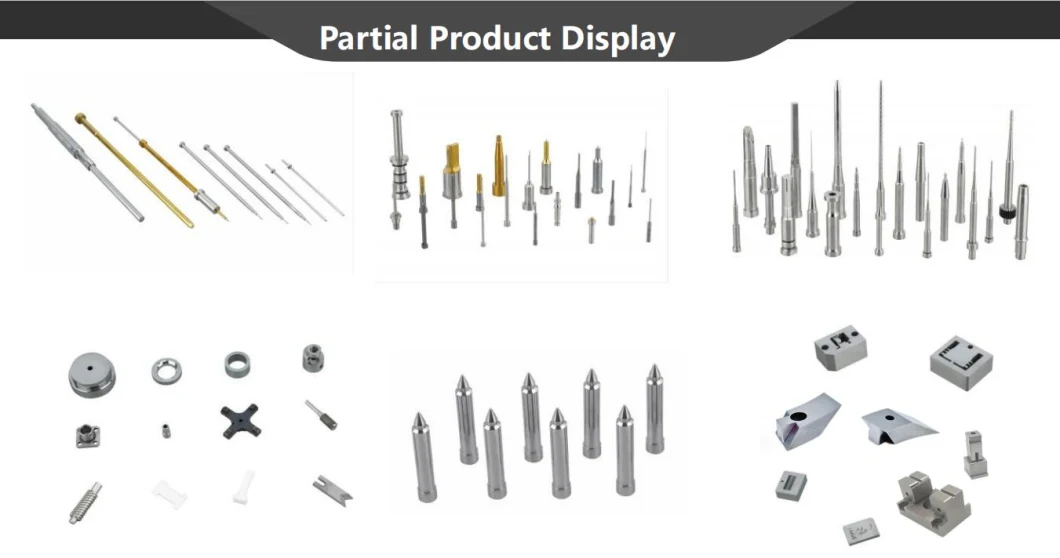

Product Description

Basic Detail

Product Feature

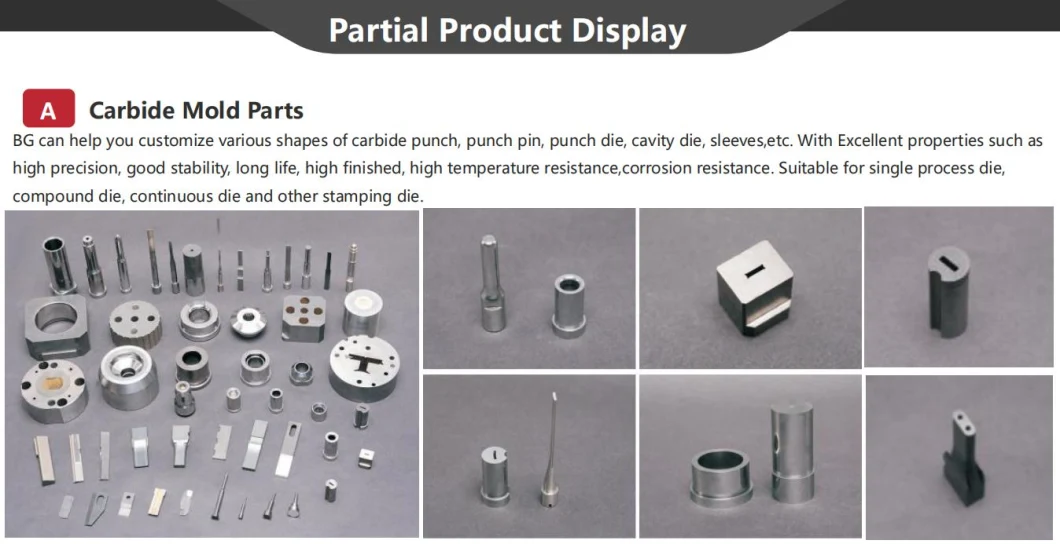

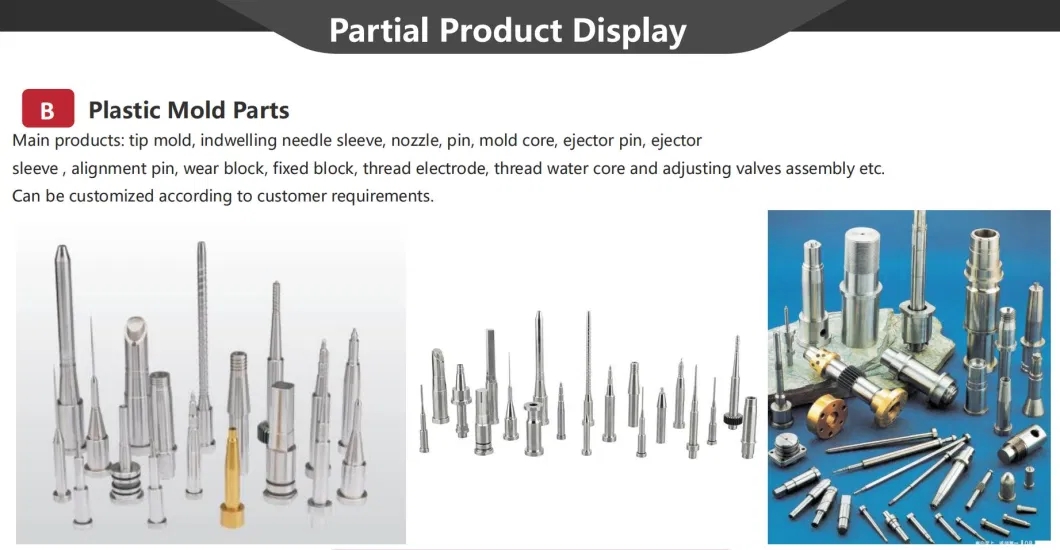

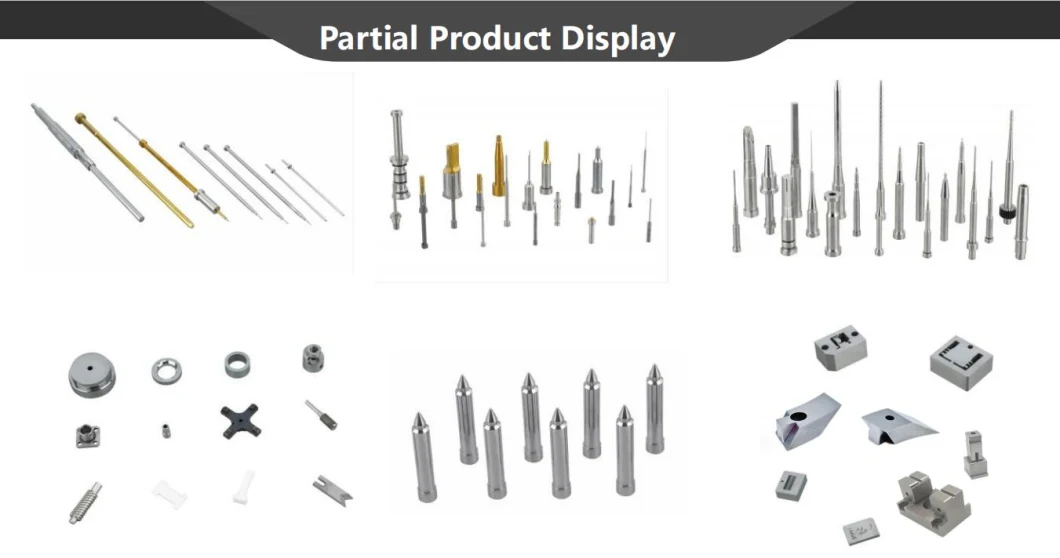

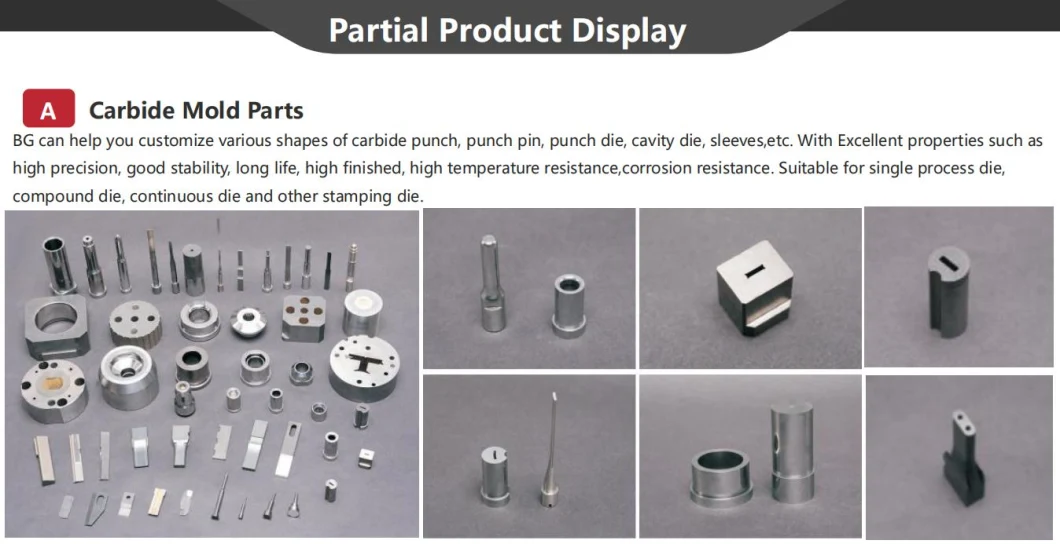

Type: we can accept customized type.

Material: Tungsten Carbide steel alloy.

Material brand:ChunBao(TAIWAN)

Material Model:RG-25 RX-10S RG-10 RX-15 BSWT15 FA-1 RX-10 BSW23

Material chemical composition:Carbon1.27-1.5 chromium4.2-4.8 molybdenum5.0-5.8 tungsten6.4-7.5 vanadium3.1-3.9

Hardness:89-95 HRA

Feature:super-hardness,high abrasion resistance,superior toughness,high strength density.

Suggested use:suitable for stamping various stainless steel,terminals,switch panel,steel case,silicon steel sheet,lithium battery,puching etc..

Company Information

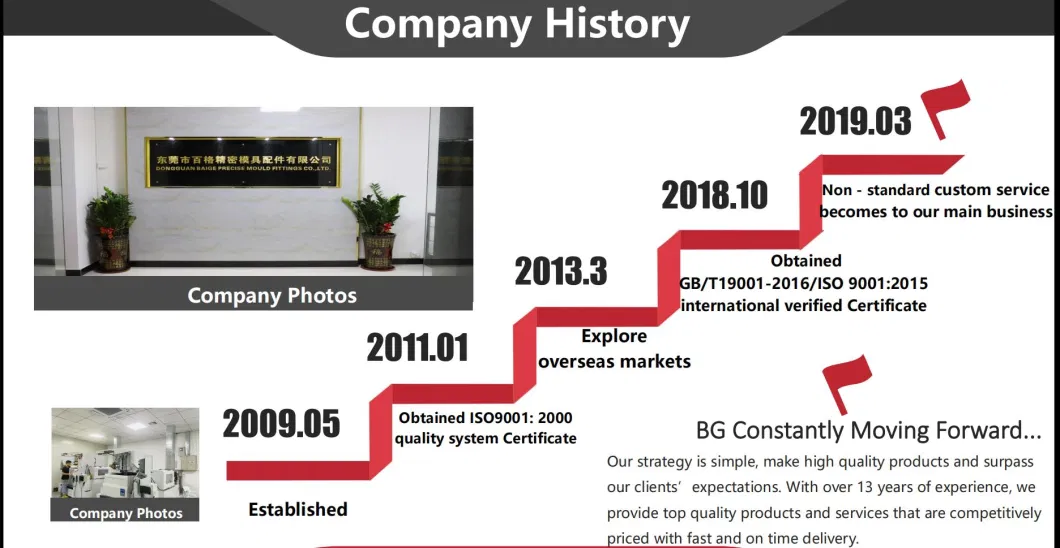

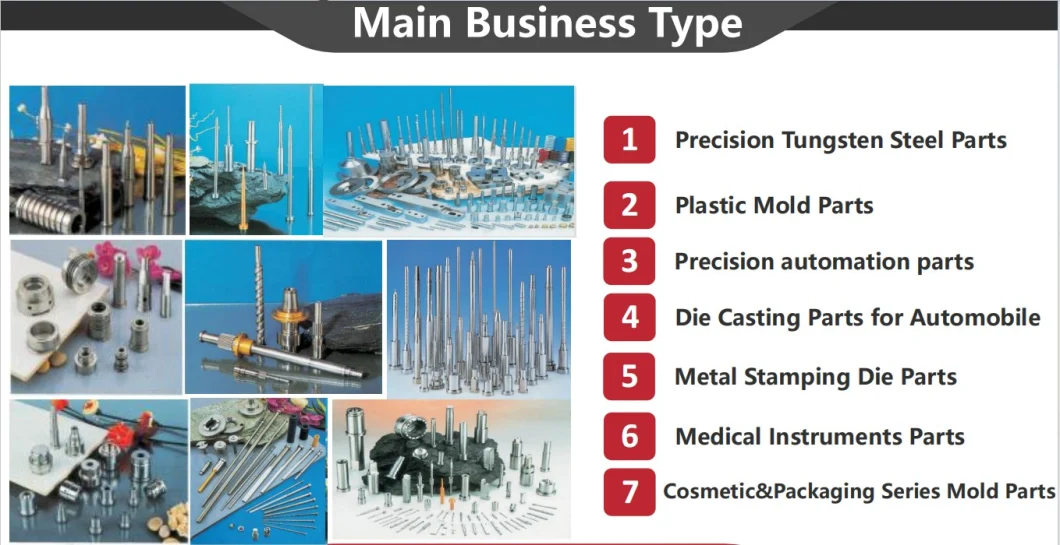

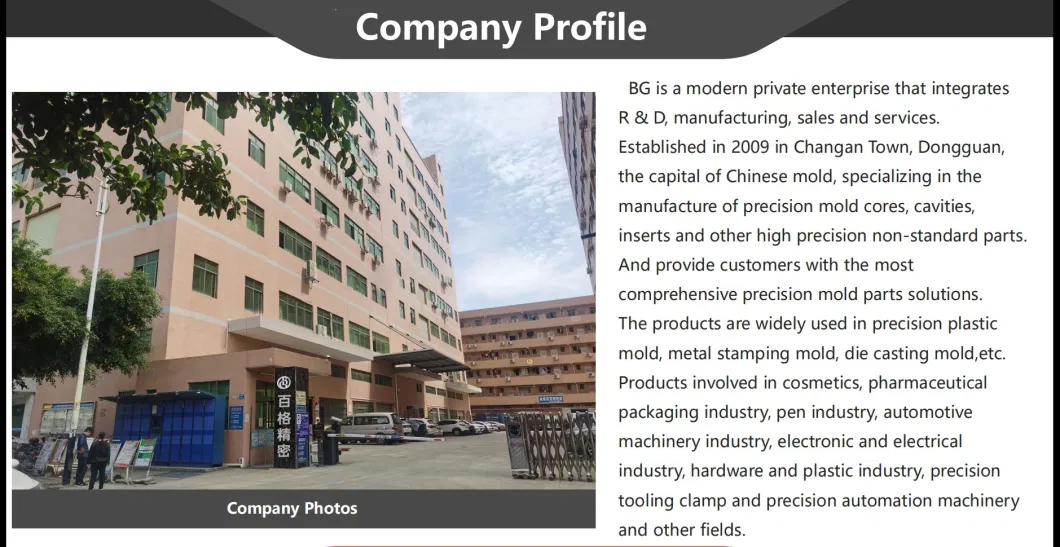

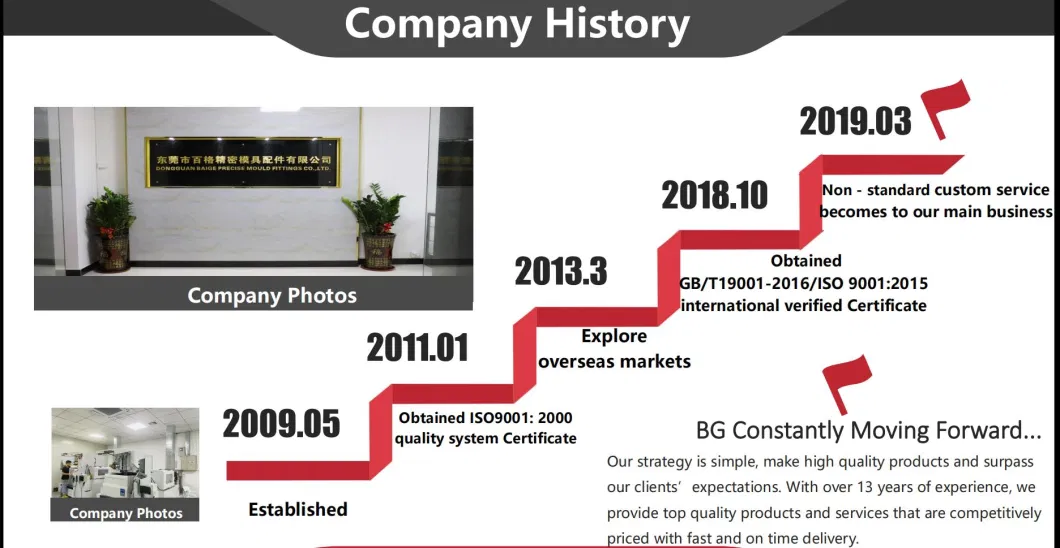

BG company was established by Mr.zhang in DongGuan ChangAn on 2009 year, It's a specialized tungsten steel parts, punch die parts , auto spare parts, etc.. factory is a OEM manufacturerd, our products are widely applied to many fields, such as Motor,lithium Battery, medical equipment, packaging stationery, electronic appliances, automotive and precision fixtures, precision automation machinery, etc.. So far, BG has been owned experienced production experience and Stable customer order, our advanced production equipment, Integrity service and Business philosophy was Won a Lot of praise in the fierce market competition, BG will always carry on the aims at " elaborated design, skilled manufacture, excellent service, continuous improvement, concern what you urgent ", let's hand to hand to achieve a win-win future.

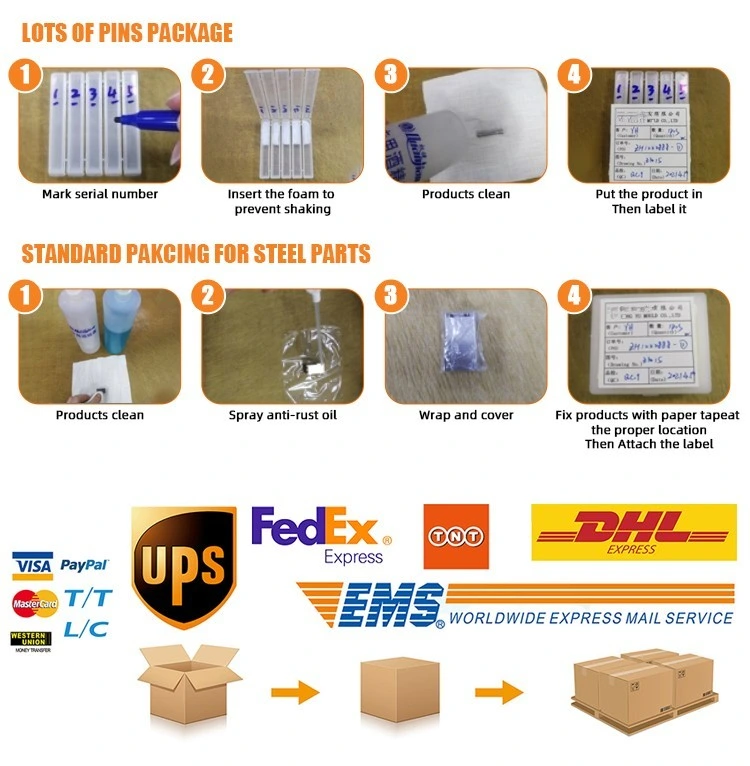

Packing&Shipping

Q:What Will You Do After Sales?

A:We have after-sales servise, when you received our products,we will follow up and await your feedback. Any question related to our products,our experienced engineers are always here for backup.

Q: How Do You Ship The Goods And How Long Does It Take To Arrive?

A:Ship by DHL, UPS, FedEx or TNT. It takes 3-5 days to arrive. Airline and sea shipping also optional. Or you can provide your forworder's information,we can contact with them to arrange the shipment.

Q: Before Shipment How To Make Sure The Mould Parts Quality?

A:You can come to our factory or let the third party for inspection, if not, we will be as your inspection worker. we will share you a video for production process details.

Q: How To Proceed An Order For Mould Parts?

A:1. let us know your requirements or application.

2. We quote according to your requirements or our suggestions.

3. Customer confirms the samples and paid the deposit for formal order.

4.We arrange the production.

Q: What About The Lead Time?

A:Normally it'll take 3-5 days for Sample preparing ,8-10 working days for mass production. but it also depend on your request and order quantity.

Q: What Type Of Material Is Best For My Design/Component?

A:Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q: I Have An Idea For A New Product, But Don't Know If It Can Be Manufactured. Can You Help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q: Do You Have Any MOQ Limit For Led Light Order?

A:Low MOQ, 1pc for sample checking is available. If custom styles, Ipc is ok, we'll do whatever we can to help you realized you ideas.

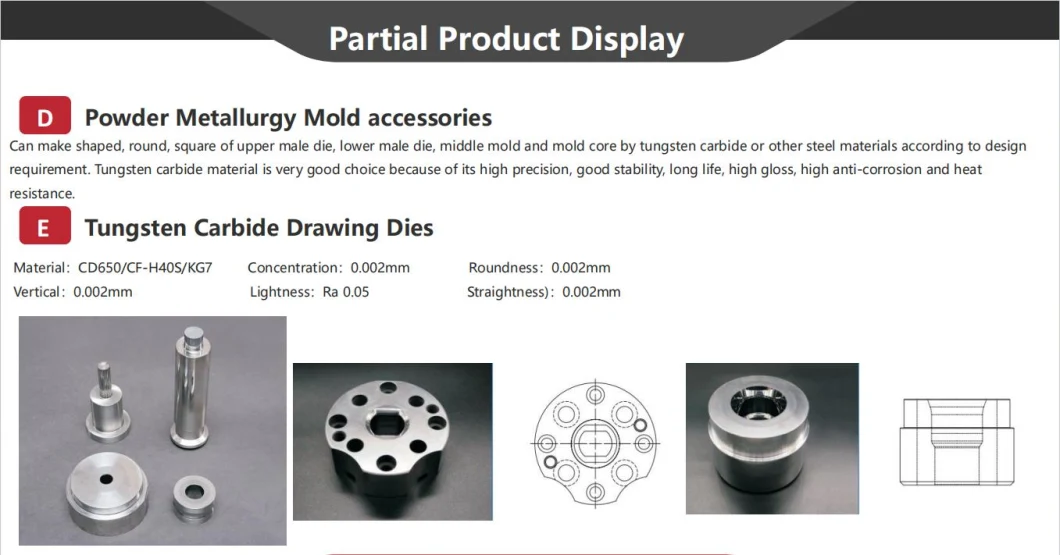

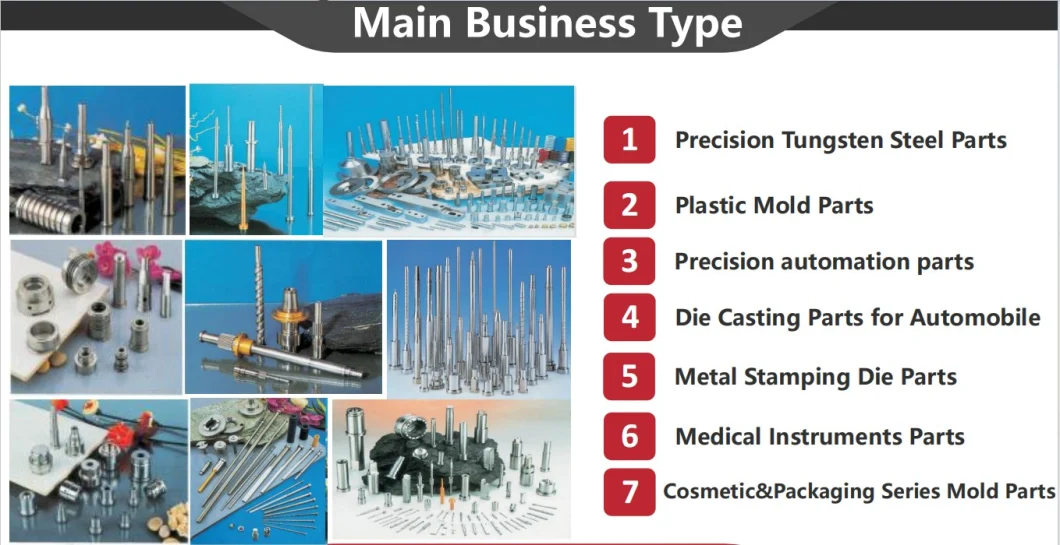

| Product name | tungsten carbide steel parts |

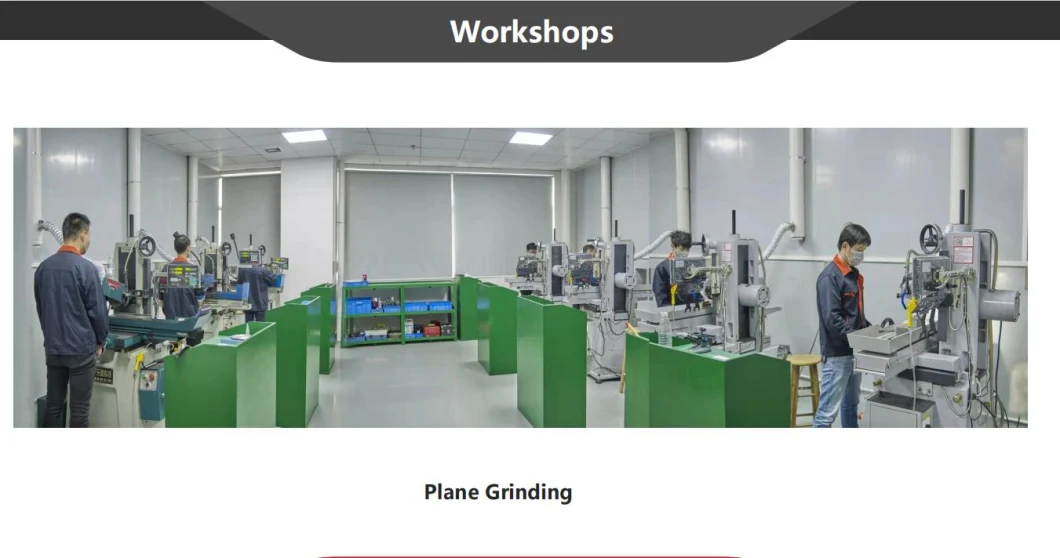

| Processing | material cutting→CNC Turning, Milling,wire EDM→inside hole Grinding →surface treatment→inspection→packing&shipping |

| Equipment | CNC milling,drilling,cutting,turning,lathe machine,Wire EDM,Table grinding,large water milling,spark machine,laser marke machine,Internal and external grinding machine, Cylindrical grinding machine, |

| Inspection instrument | Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester.Height tester, |

| Tolerance | ±0.002mm |

| Surface Treatment | Oxidizing, Coating,TiCN,TiN,Aitain,Ticrn,Nitrding,Black oxygened,Black coating etc |

| Application | Medical Instruments/Electronic/ Industrial// Automation / motorcycle/3D printer |

| Company style | OEM Manufacturer |

| Drawing | 2D/3D/PDF/stemp/gsw |

| Surface Roughness | Ra0.2 |

| manufacture size | From 0.1mm to 6000mm |

| QC System | Pre-inspection, intermediate inspection, post-inspection, three procedures to ensure that each product is qualified |

| Quality assurance | 99.9% qualified |

| Shipment | international express(DHL FedEx TNT UPS EMS SF Express) |

| Sample | Sample can be provided. |

| After-Sales Service | if product is damaged,refund or repair for customer,Until the customer is satisfied |

Product Feature

Type: we can accept customized type.

Material: Tungsten Carbide steel alloy.

Material brand:ChunBao(TAIWAN)

Material Model:RG-25 RX-10S RG-10 RX-15 BSWT15 FA-1 RX-10 BSW23

Material chemical composition:Carbon1.27-1.5 chromium4.2-4.8 molybdenum5.0-5.8 tungsten6.4-7.5 vanadium3.1-3.9

Hardness:89-95 HRA

Feature:super-hardness,high abrasion resistance,superior toughness,high strength density.

Suggested use:suitable for stamping various stainless steel,terminals,switch panel,steel case,silicon steel sheet,lithium battery,puching etc..

Company Information

BG company was established by Mr.zhang in DongGuan ChangAn on 2009 year, It's a specialized tungsten steel parts, punch die parts , auto spare parts, etc.. factory is a OEM manufacturerd, our products are widely applied to many fields, such as Motor,lithium Battery, medical equipment, packaging stationery, electronic appliances, automotive and precision fixtures, precision automation machinery, etc.. So far, BG has been owned experienced production experience and Stable customer order, our advanced production equipment, Integrity service and Business philosophy was Won a Lot of praise in the fierce market competition, BG will always carry on the aims at " elaborated design, skilled manufacture, excellent service, continuous improvement, concern what you urgent ", let's hand to hand to achieve a win-win future.

Packing&Shipping

Q:What Will You Do After Sales?

A:We have after-sales servise, when you received our products,we will follow up and await your feedback. Any question related to our products,our experienced engineers are always here for backup.

Q: How Do You Ship The Goods And How Long Does It Take To Arrive?

A:Ship by DHL, UPS, FedEx or TNT. It takes 3-5 days to arrive. Airline and sea shipping also optional. Or you can provide your forworder's information,we can contact with them to arrange the shipment.

Q: Before Shipment How To Make Sure The Mould Parts Quality?

A:You can come to our factory or let the third party for inspection, if not, we will be as your inspection worker. we will share you a video for production process details.

Q: How To Proceed An Order For Mould Parts?

A:1. let us know your requirements or application.

2. We quote according to your requirements or our suggestions.

3. Customer confirms the samples and paid the deposit for formal order.

4.We arrange the production.

Q: What About The Lead Time?

A:Normally it'll take 3-5 days for Sample preparing ,8-10 working days for mass production. but it also depend on your request and order quantity.

Q: What Type Of Material Is Best For My Design/Component?

A:Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q: I Have An Idea For A New Product, But Don't Know If It Can Be Manufactured. Can You Help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q: Do You Have Any MOQ Limit For Led Light Order?

A:Low MOQ, 1pc for sample checking is available. If custom styles, Ipc is ok, we'll do whatever we can to help you realized you ideas.