Basic Info.

Product Description

Introudction:

Zonco has been specialized in the cemented tungsten carbide industry more than 10 years,and able to manufacture all kinds of tungsten carbide parts and alloy wear resisting parts based on customers' drawings and material specification requirement(prodcuts inclduing AP* series,GE series, MWD series, QDT series, SL series,etc.) welcome to contact us for more details.

Application:

Tungsten carbide, not to be confounded with tungsten alloy, which is metal, is the ceramic of choice when it comes to wear and abrasion resistance. Cutting tools for steel and tool steel are made from tungsten carbide. It is also used extensively in the mining industry as a button insert for crushing rocks.

The high thermal performance of the tungsten carbide keeps the nozzle tip hot, thus allowing faster printing speed without sacrificing the quality.

Tungsten carbide has exceptional wear resistance due to its high hardness. Both the nozzle hole size and height will always stay the same, no matter how long or how hard you use it.

Compared to a reference brass nozzle, the tungsten carbide nozzle is much easier to extrude. In fact, the output flow can be increased by around 80% while having the same results.

Main Products lines:

1.Radial Thrust Bearing & PDC,TC Bearing

2.Tungsten Carbide Nozzles and Teeth

3.Valve Stem/plug and seats

4.MWD & LWD Carbide Parts

5.Carbide Parts for Downhole Tools

6.Carbide Wear Parts for Mechanical Equipments

7.Carbide Drilling Dies

8.Carbide Buttons

9.Other Carbide Wear Parts used in extreme complex and severe working conditions (high temperature, strong corrosion and wear)

Products pictures are as Follow:

1. Radial Thrust Bearing & PDC,TC Bearing

2. Tungsten Carbide Nozzles and Teeth

3. Valve Stem/plug and Seats

4. MWD & LWD Carbide Parts

5. Carbide Parts for Downhole Tools

6.Carbide Wear Parts for Mechanical Equipments

7. Carbide Drilling Dies

8. Carbide Buttons

9. Other Carbide Wear Parts used in extreme complex and severe working conditions (high temperature, strong corrosion and wear)

Company Advantages:

1.Experienced with high producing technology and facilities

2. Varying sizes and customized needs available

3. Quality and quantity assured

4. Factory direct price

5. Lower cost and more flexible production management

Tungsten Carbide Grades,Properties and Application

Grade | WC% | Co/Ni% | Physical and mechanical properties | Grain size μm | Recommended application | ||

Density g/cm3 | TRS N/mm2 | Hardness HRA | |||||

| ZG01 | 100 | 0 | 15.3-15.5 | 1200 | 95.5 | 0.3 | Ultra high hardness, high wear resistance, corrosion resistance, with certain damage resistance |

| ZG04X | 96 | 4 | 15.0-15.2 | 1600 | 92.8 | 0.8-1.0 | Suitable for wire drawing die, non-ferrous metal wire tensile wear-resisting parts |

| ZG06 | 94 | 6 | 14.8-15.1 | 2500 | 90.0 | 1.2 | Good wear resistance, good compression resistance, suitable for wear resistance and high pressure resistance parts, good thermal rigidity |

| ZG06X | 94 | 6 | 14.8-15.1 | 2400 | 91.5 | 1.0 | |

| ZG06A | 94 | 6 | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 | |

| ZG08 | 92 | 8 | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for usual wear - resistant parts, molds, general tools, etc |

| ZG10.2 | 90 | 10 | 14.3-14.6 | 3800 | 91.8 | 0.7 | Sub-fine tungsten carbide particles, good general performance |

| ZG10X | 90 | 10 | 14.3-14.6 | 4000 | 92.2 | 0.6 | Ultra fine tungsten carbide particles, excellent heat resistance |

ZG11 | 89 | 11 | 14.3-14.7 | 2800 | 88.5 | 1.2-1.6 | Anti-wear, anti-erosion, good comprehensive mechanical strength, suitable for wear-resistant parts in the petroleum, chemical and mechanical industries. |

| ZG12X | 88 | 12 | 14.2-14.5 | 3000 | 89.5 | 1.0-1.2 | Anti-erosion, good comprehensive mechanical strength, suitable for impact-resistant wear-resistant parts, molds, and roller rings. |

| ZG15 | 85 | 15 | 13.8-14.2 | 3000 | 86.5 | 1.2-1.6 | |

ZG15X | 85 | 15 | 13.8-14.2 | 4500 | 89.0 | 0.7 | Sub-fine tungsten carbide particles, with good wear resistance and excellent toughness, which is suitable for making integral stamping dies, anti-vibration toolholders, etc. |

| ZG20 | 80 | 20 | 13.4-13.8 | 3100 | 85.0 | 1.0 | Excellent wear resistance and toughness |

| ZN06 | 94 | 6 | 14.5-14.9 | 2000 | 90.0 | 1.2 | Non-magnetic alloy, suitable for sealing ring, non-magnetic wear-resistant parts and corrosion-resistant parts. |

| ZN09 | 91 | 9 | 14.3-14.6 | 2300 | 89.0 | 1.2-1.6 | |

| ZN11 | 89 | 11 | 14.0-14.3 | 2600 | 88.0 | 1.2 | |

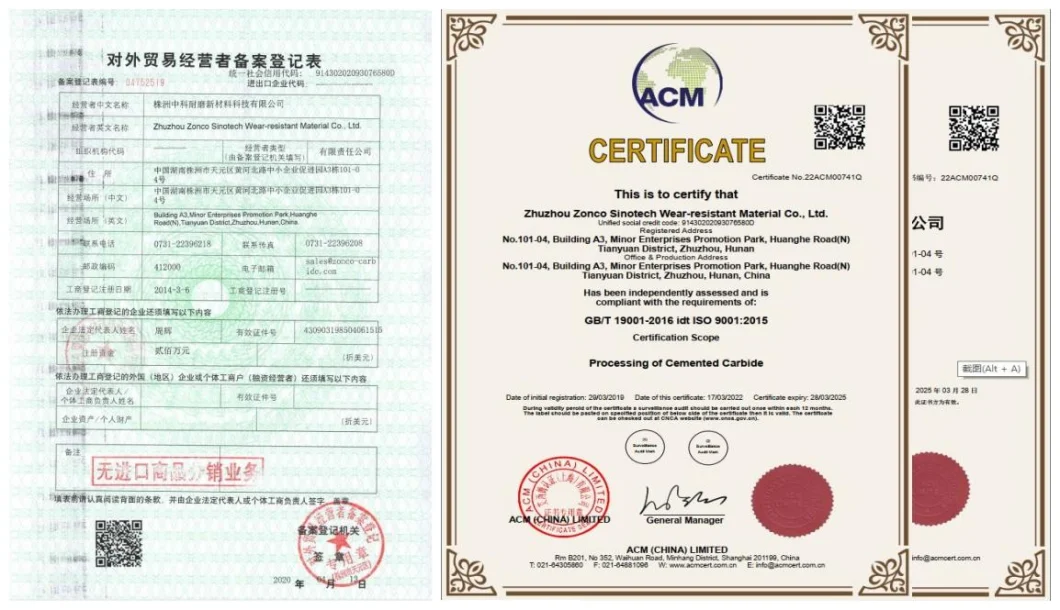

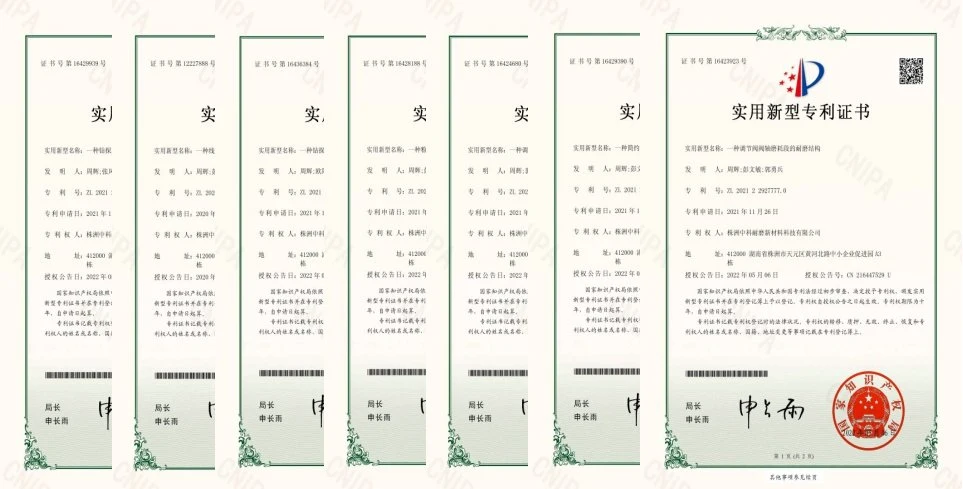

Bussiness and Patent License of Cemented Tungsten Carbide

Welcom to visit our factory in Zhuzhou,China! and please feel free to contact me if you looking forward to high quality supplier of cemented tungsten carbide wear resistant parts customized

Benjamin Yan

Company Add: Building A3, Minor Enterprises Promotion Park, Huanhe Road(N), Tianyuan District, Zhuzhou, Hunan, China