Basic Info.

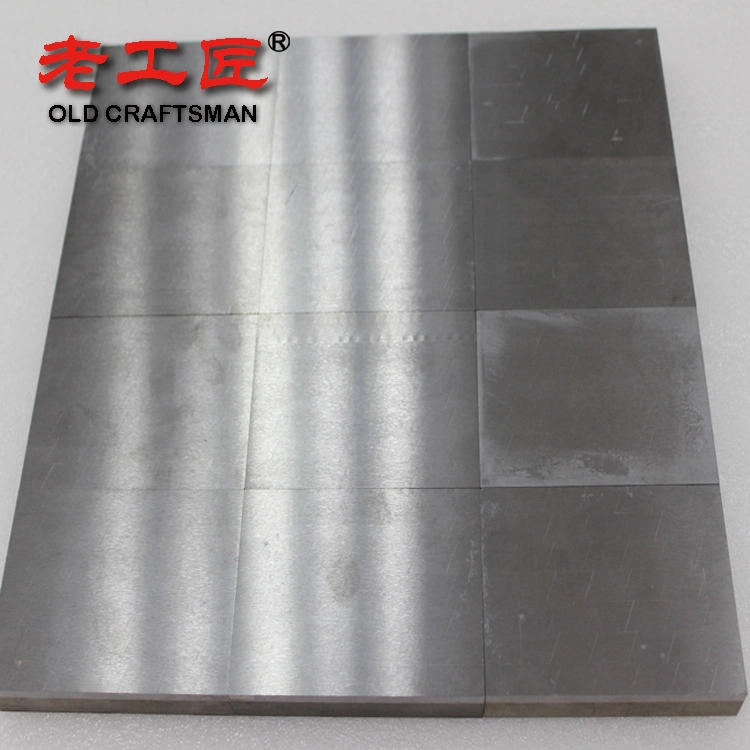

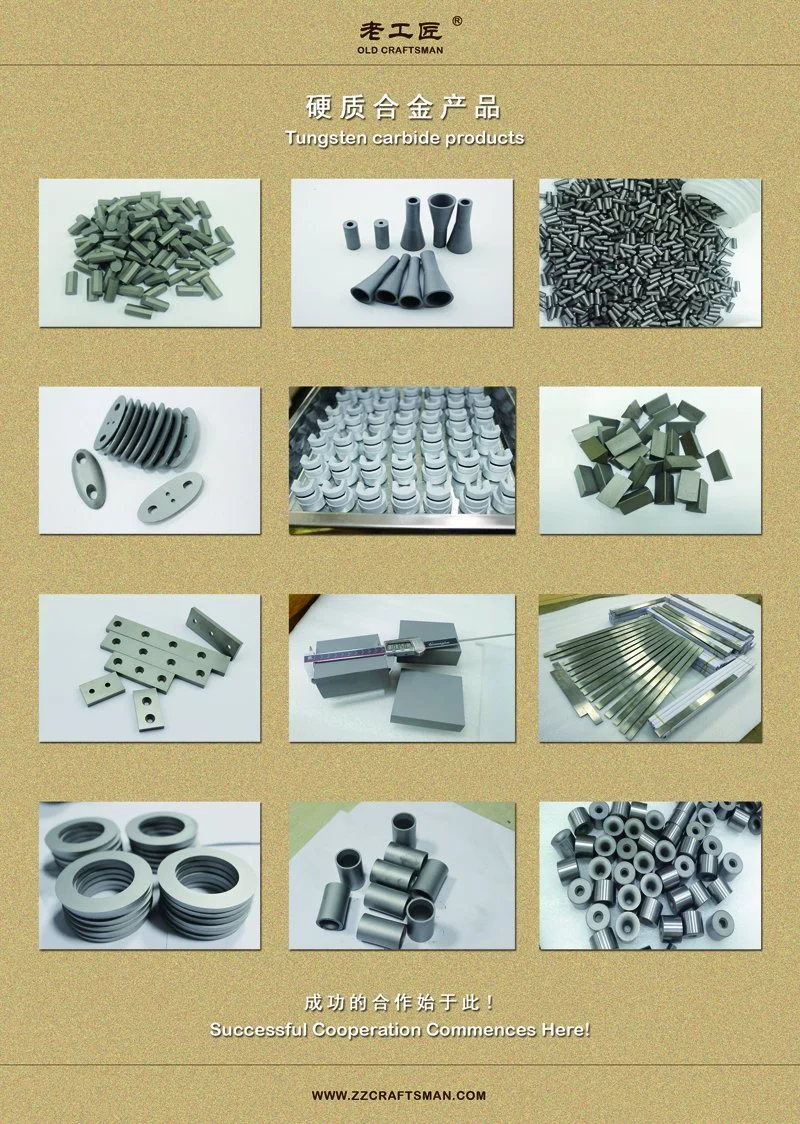

Product Description

1. 100% raw material to produce tungsten carbide products.

2. Hip sintered, high hardness, high wear resistance

3. Various sizes and full types available

4. Reasonable price,Fast delivery time

5. OEM Customized(small order accepted,professional technical support)

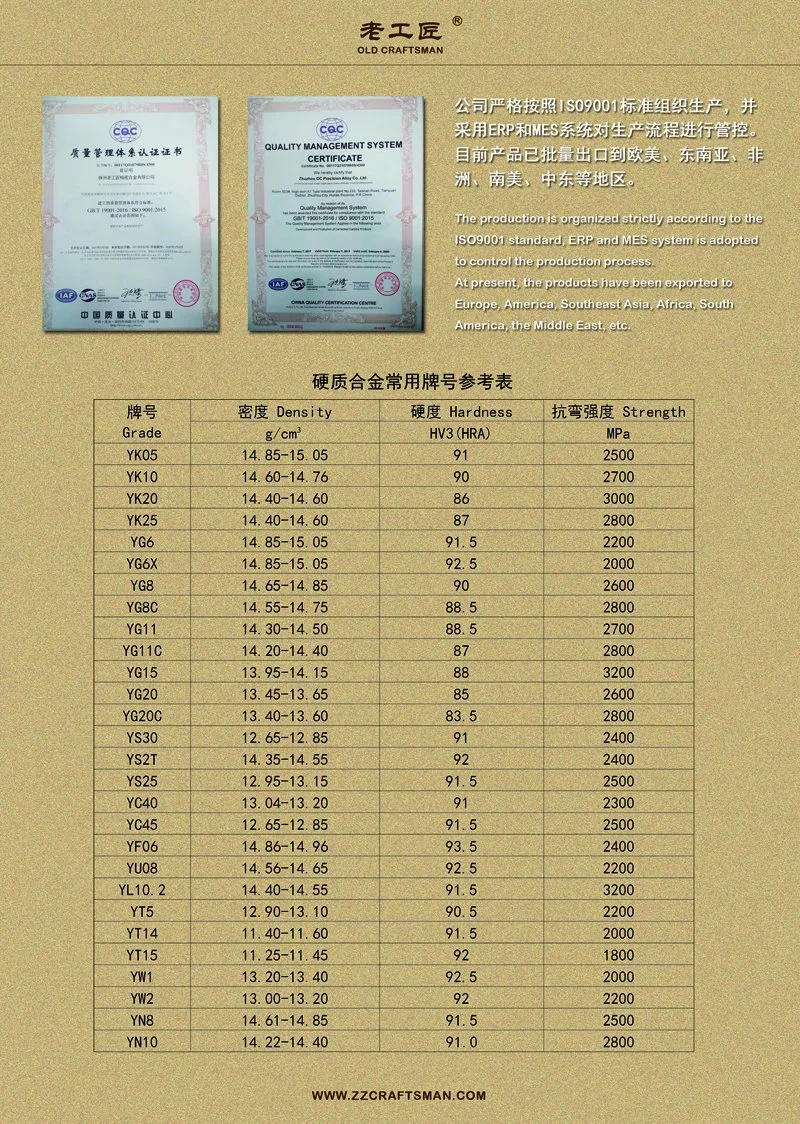

6.ISO 9001 Certification

More details of specific type, please inform us

Product information

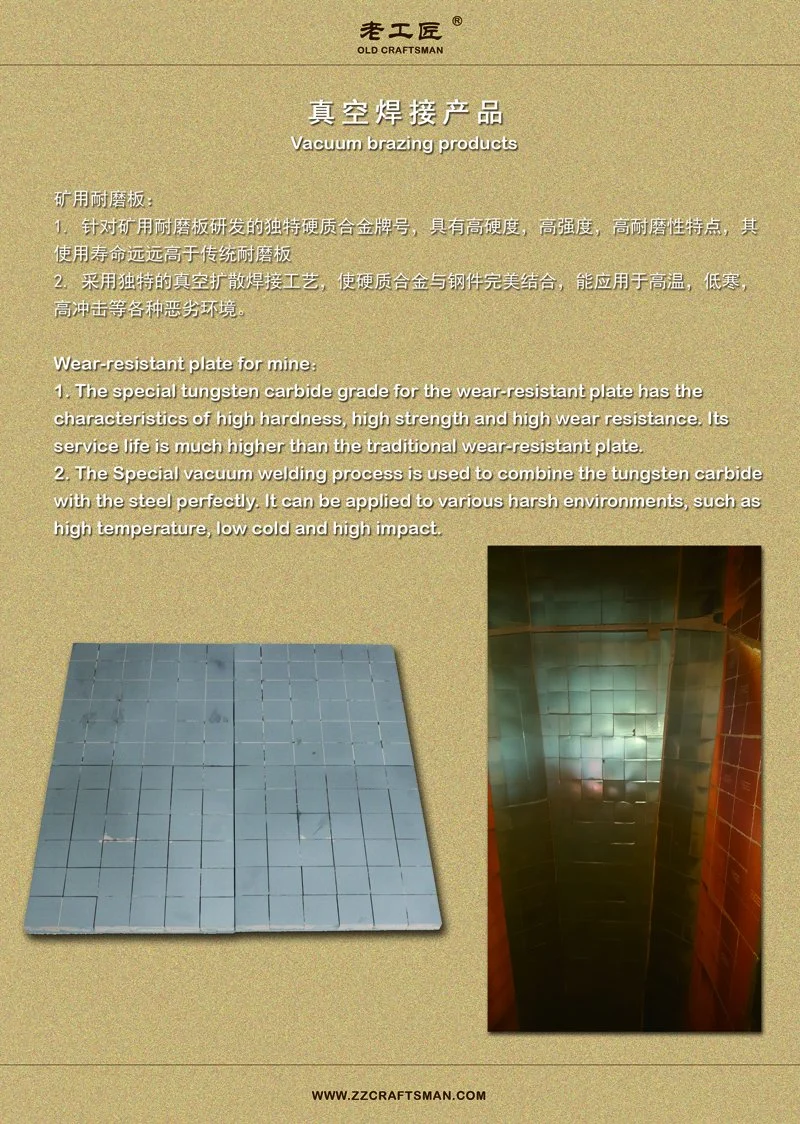

After years of researching, we gathered a good knowledge of Vacuum Welding between carbide and steel on a relatively big area , we know how to release the Inner stress of Welding to improve the Welding Quality.

Our this items is a new type of Heat resisting brick mould, adopted vacuum welding between carbide and steel technology. Currently we use adhesive technology to connect the carbide part and steel part, while the carbide is easy to get off from the steel after servral time making goods. One set mould for making trick should be used for 50000times, which would waste much time to make face milling grinding for the mould. Our new moulds technology solve this problem perfectly.

The advantages for Vacuum welding carbide and steel die

The combination of carbide and steel material, meet the feature of moulds, such as wear resistance, heat resistance and strengths requirements, as well as long life. As a part of mould, steel saves the production cost effectively.

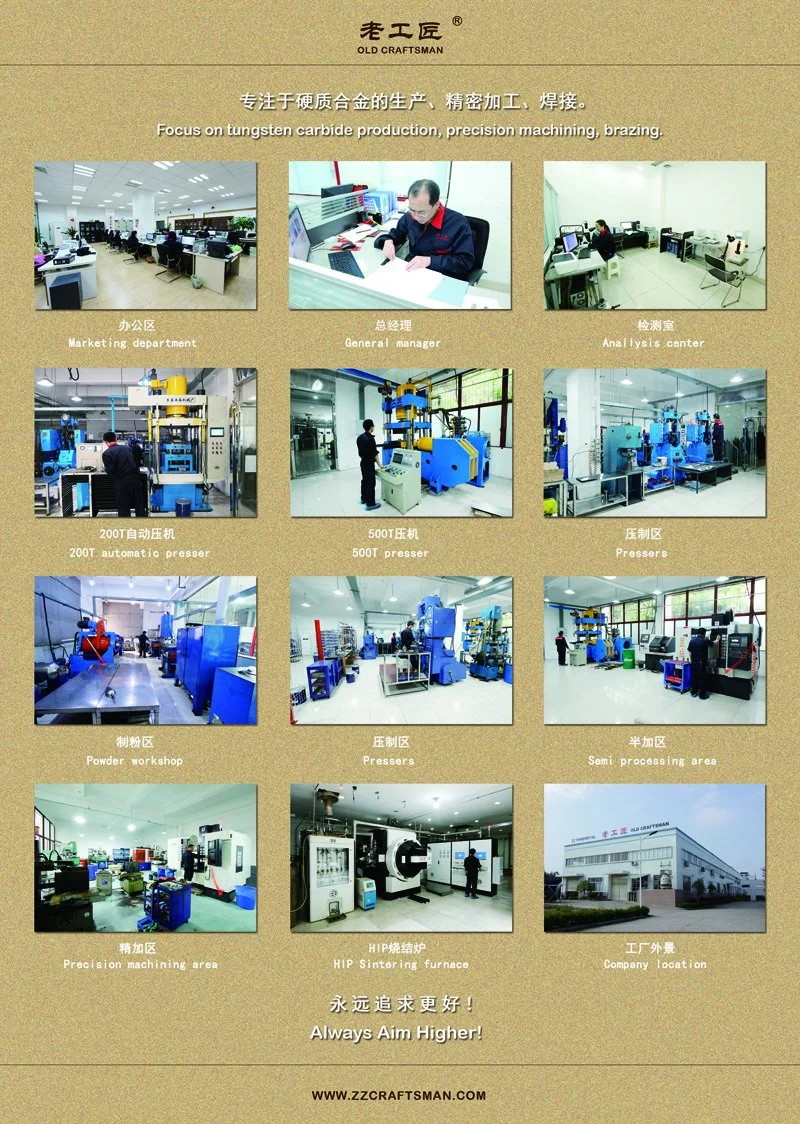

Company Information

Applications

Vacuum welding carbide and steel die are used as the wear part of the mould, mainly for the mould of brick making.

FAQQ: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<1000USD, 100% in advance. Payment>1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us!