Basic Info.

Model NO.

2.0*330

Material

Tungsten Carbide

Certification

ISO 9001:2008, ISO 9001:2000, GS, CE

Grain Sizes Selection

Ultra Fine, Fine, Medium, Coarse

Surface Finishing

Polished and Unpolished

Main Using Purpose

Carbide Body for Drill Bits/ Endmills / Reamers

Wc+Co Powder

100% Virgin Material

Advantage

Good Quality with Competitive Prices

Transport Package

Safe Exporting Packing

Specification

dia6*330

Trademark

GQ CARBIDE

Origin

Zhuzhou

HS Code

82090090

Production Capacity

2000 Tons Per Year

Product Description

Company Profile

We, GQ CARBIDE TOOLS CO.,LTD, is professional and with more than 28 years' experience of hard mental products.

Our main products include tungsten carbide rods,strips,plats,disc cutters,etc.

And our carbide are widely used for machining cast iron, steel, stainless steel, aluminum, copper, rubber and so on.

Production Advantage

Unground Solid Tungsten Carbide Rods for Machining Steel,Copper,Stainless

Large stock of rods

Immediate Delivery

High performance

Grade Introduction

Recommended Applications

Unground Solid Carbide Rods

Unground Cut-Length Solid Rods

PCB Rods

Grade Introduction

Recommended Applications

We, GQ CARBIDE TOOLS CO.,LTD, is professional and with more than 28 years' experience of hard mental products.

Our main products include tungsten carbide rods,strips,plats,disc cutters,etc.

And our carbide are widely used for machining cast iron, steel, stainless steel, aluminum, copper, rubber and so on.

Production Advantage

Unground Solid Tungsten Carbide Rods for Machining Steel,Copper,Stainless

Large stock of rods

Immediate Delivery

High performance

Grade Introduction

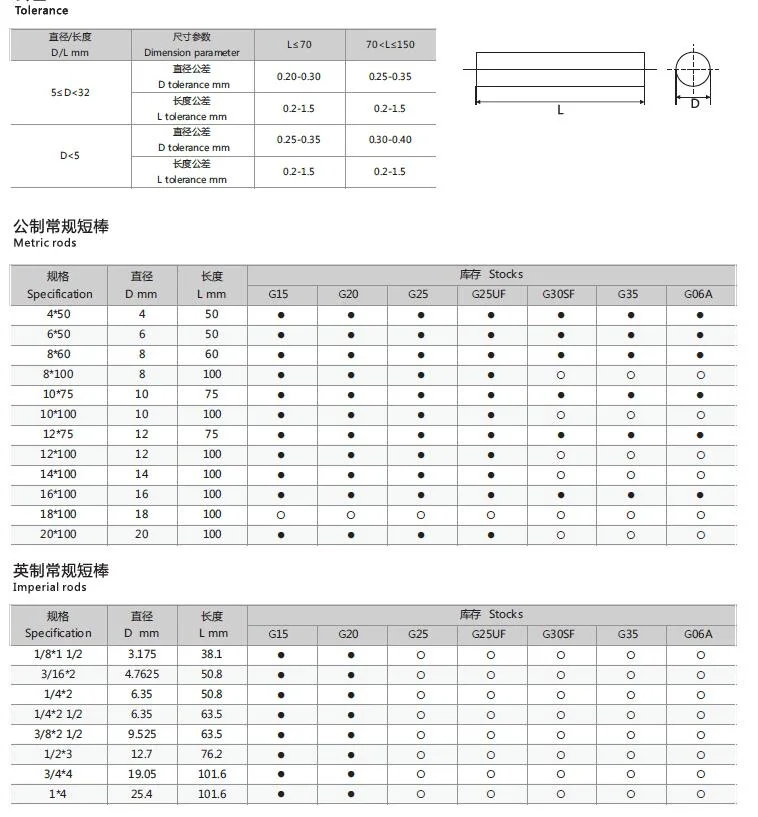

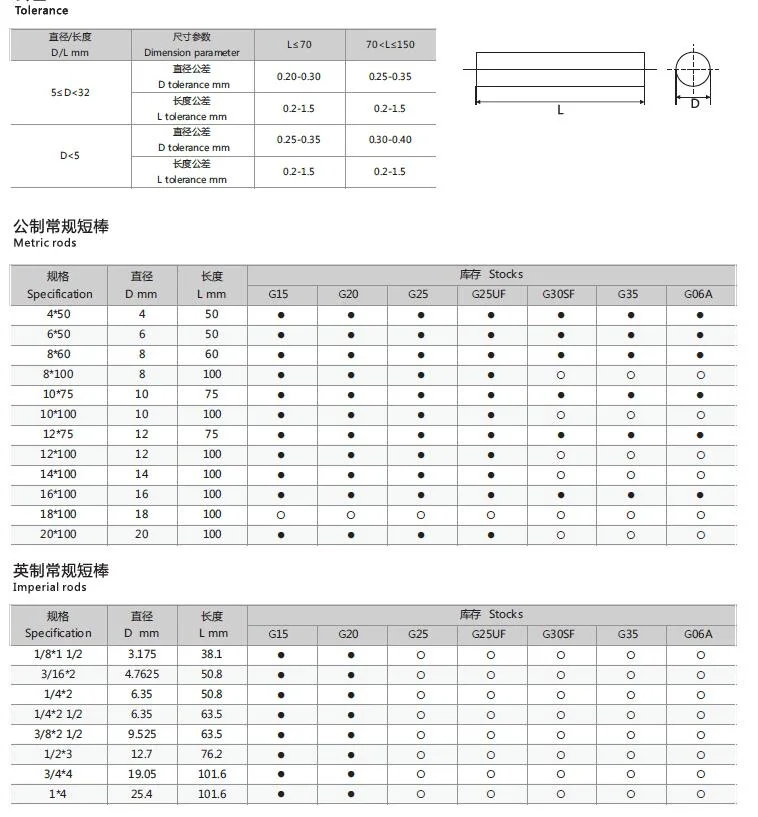

| Grade | Cobalt content Co% | Density g/cm3 | Hardness HV30 | Hardness HRA | Strength N/mm2 | K1C MPa.m1/2 | Grain size μm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G06A | 6 | 14.9 | 1740 | 92.5 | 3500 | 12 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G15 | 10 | 14.5 | 1600 | 91.5 | 4000 | 11 | 0.8 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G20 | 10 | 14.5 | 1660 | 91.8 | 4000 | 10 | 0.7 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G25 | 12 | 14.2 | 1750 | 92.3 | 4000 | 12 | 0.6 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G25UF | 12 | 14.2 | 1780 | 92.5 | 4200 | 12 | 0.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G30SF | 10 | 14.4 | 1700 | 92.3 | 4200 | 12 | 0.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G35 | 9 | 14.3 | 1960 | 93.7 | 4000 | 10 | 0.3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recommended Applications

Unground Solid Carbide Rods

Unground Cut-Length Solid Rods

PCB Rods

Grade Introduction

| Grade | Cobalt content Co % | Density g/cm3 | Hardness HV30 | Hardness HRA | Strength N/mm2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| GSF20A | 6.5 | 14.7 | 2150 | 94.3 | 4000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| GSF15A | 5 | 14.9 | 2000 | 94 | 4000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recommended Applications