- Overview

- Quick Information

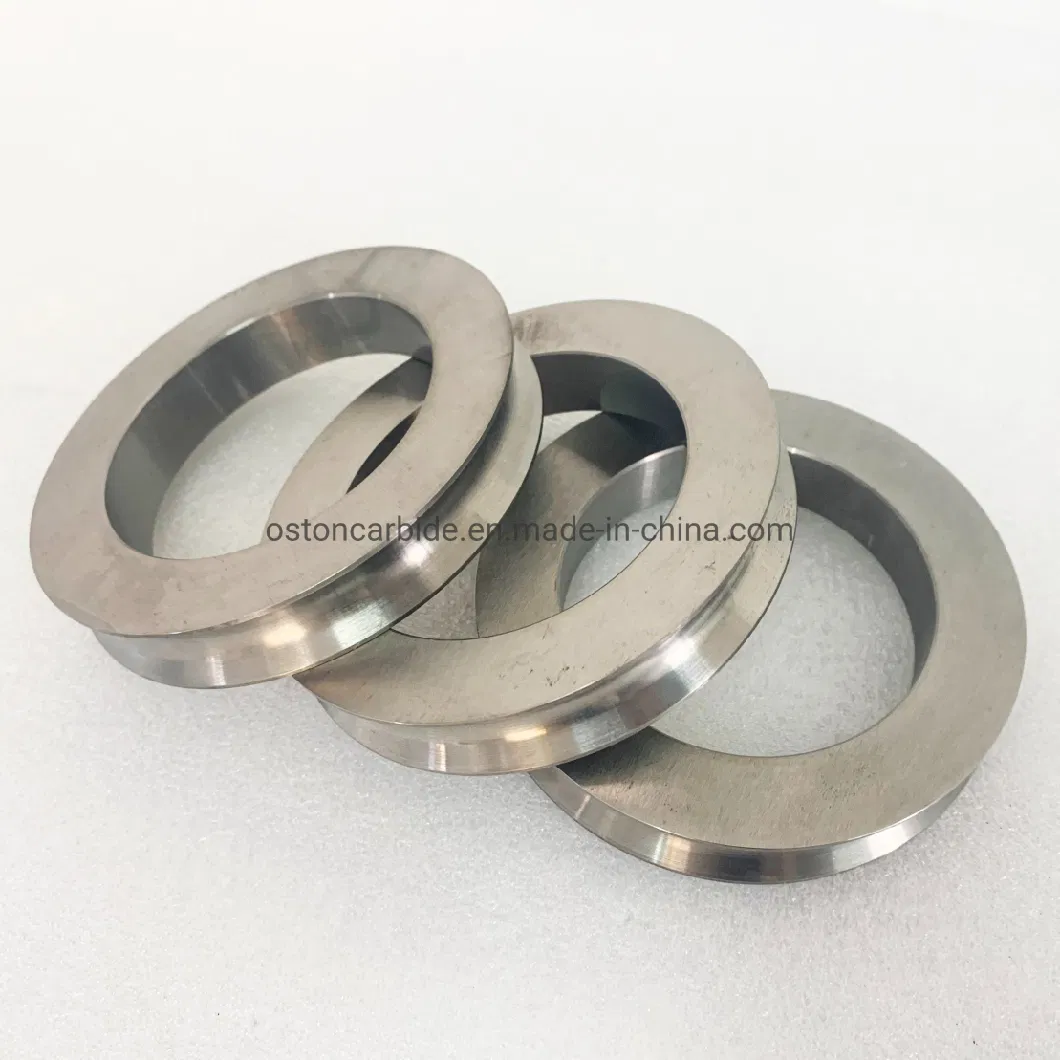

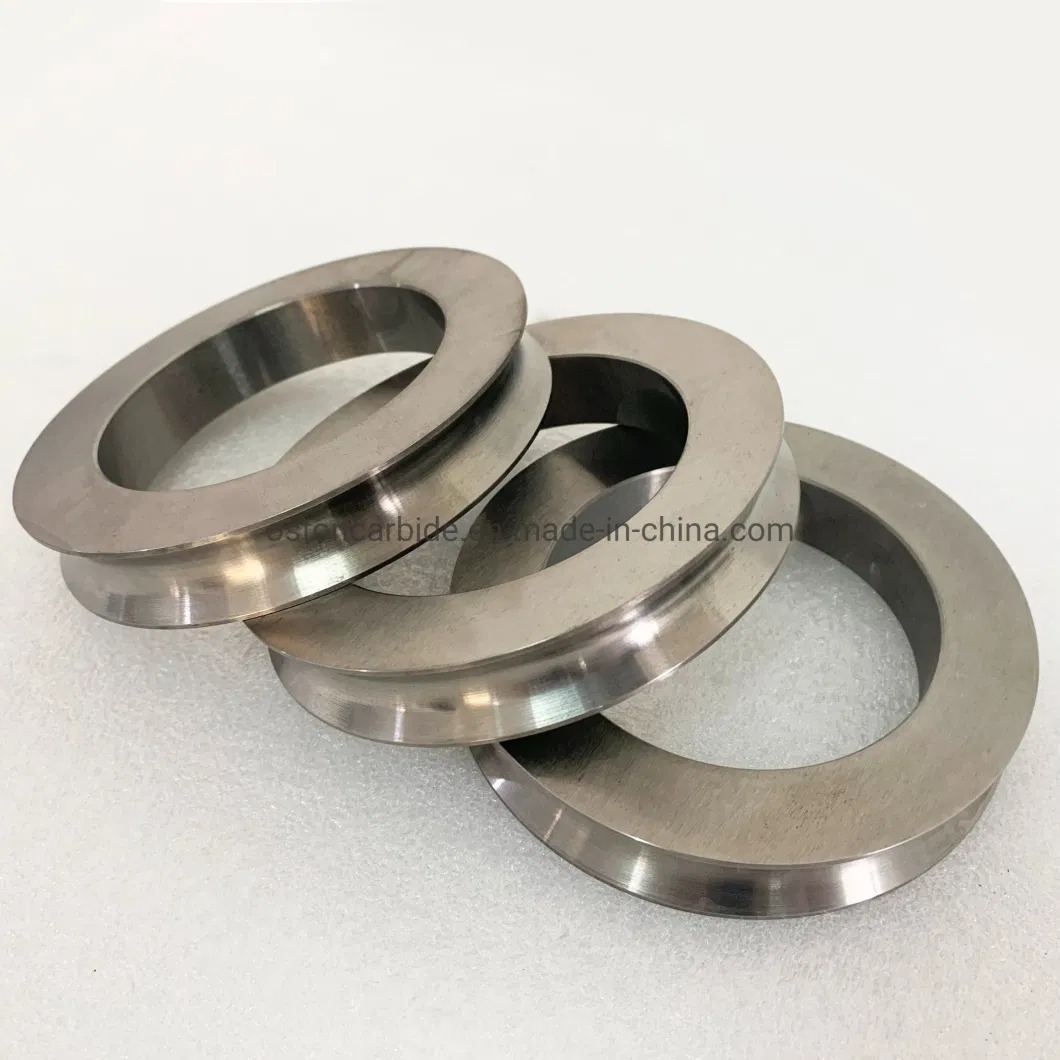

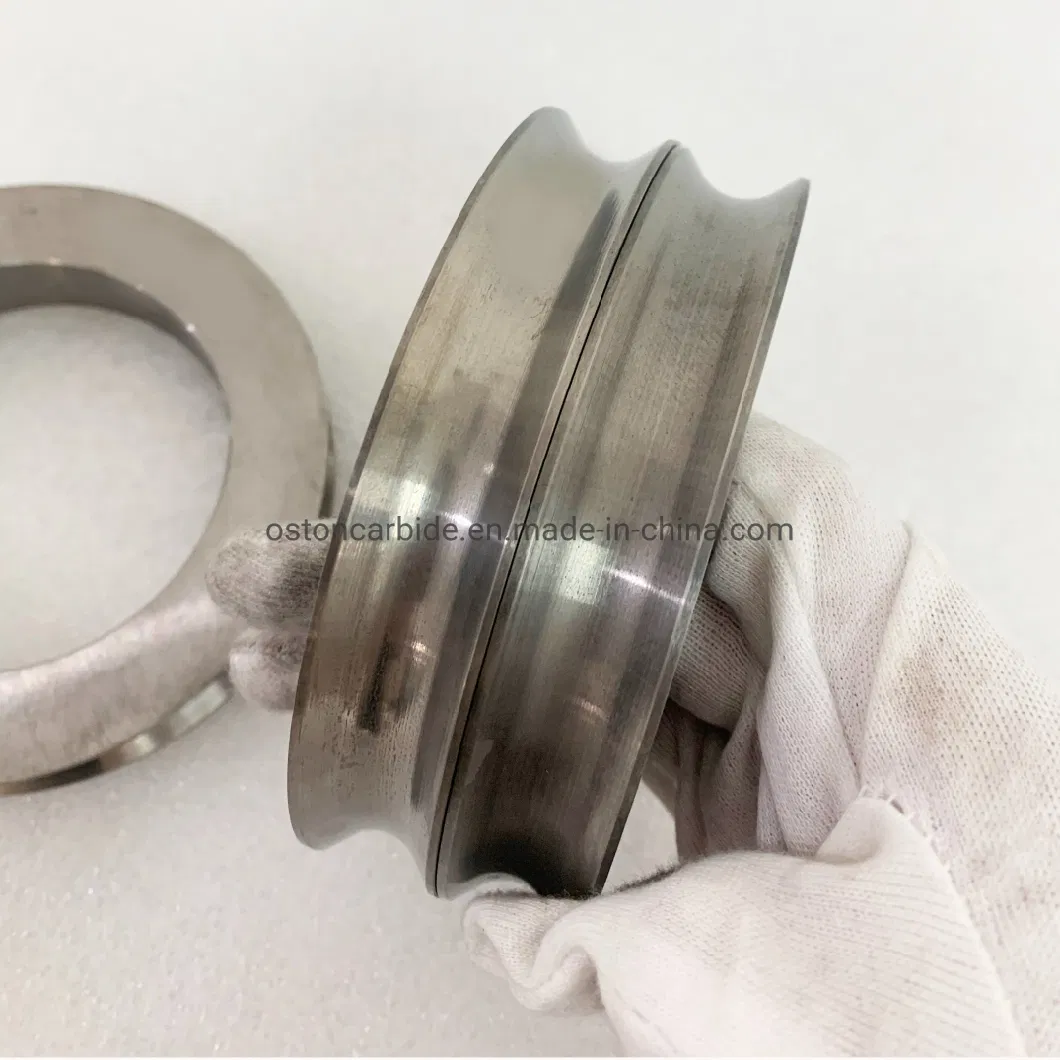

- Detailed Photos

- Main Dimensions

- Quality Control

- About Oston Carbide

Basic Info.

Product Description

Wear-Resistant Tungsten Carbide Descaling Rolls Used for Mechanical Descaling of Entry Rod in Reduction Mills

Wire descaling and straightening is a necessary process in steel plant before rolling mill, tungsten carbide descaling rolls are important accessories for mechanical descaling of entry rod in reduction mills for clean purpose,steel descaling rolls were used in the past and they were replaced by tungsten carbide descaling rolls gradually.

Knowns as "Hard alloy",tungsten carbide has obvious advantages compared with too stell rolls,including ultra wear resistance,high impact strength,high temperatuer resistance,corrosion resistance. The service time of tungsten carbide rolls is 12-15 times than that of steel rolls.

Tungsten carbide rolls can be devided into types as below according to the specific purpose:

Wire Descaling Roller

Wire descaling rolls can be made in tungsten carbide material or tool steel material and are used for mechanical descaling of entry rod in reduction mills.

Wire Stress-relieving Roller

Wire stress-relieving Rolls also can be made in T.C. material or tool steel material ,they are used to improve the mechanical property of the cold rolling wire.

Wire Straightening Roller

Wire straightening roll is a important component for wire straightening machine,and its main function is to eliminate unwanted curvature caused by winding wire or rod into coils or onto reels before further process.

Q:Is OSTON CARBIDE producer ?

A:OSTON CARBIDE is a exporting subsidiary for our parent company,which is a manufacturer of tungsten carbide and diamond wheels since 1998,you will get both manufacturing prices and good services here.

Q:What kind of products and service could OSTON supply ?

A:OSTON has been specializing in carbide solutions for clints more than 20 countries,which includes design and manufacturing of various carbide parts.

Q: Is there any certification for products of OSTON ?

A: Yes,All products from OSTON have been endorsed with the ISO9001:2015 certification.

Q:Can a drawing be supplied to OSTON for further design ?

A: Yes,we encourage sending as more information as possible,drawing and sketch are welcome for specific quotation,even a sample could be sent to OSTON for further design.

Q:When can I get the offer after sending inquiry ?

A:Our sales operates between 9:00 am to 6:00 pm Monday to Friday,Offer is usually supplied within 24 hours after we got your inquiry,if you are urgent to get the price,please call us or send email so that we'll take it as priority.

Q:How long time I need spend on waiting for my goods ?

A:Usual delivery time is 15-18 days after 30% down payment is received,please confirm with us before placing the order if you need urgent turnaround delivery.