Basic Info.

Product Description

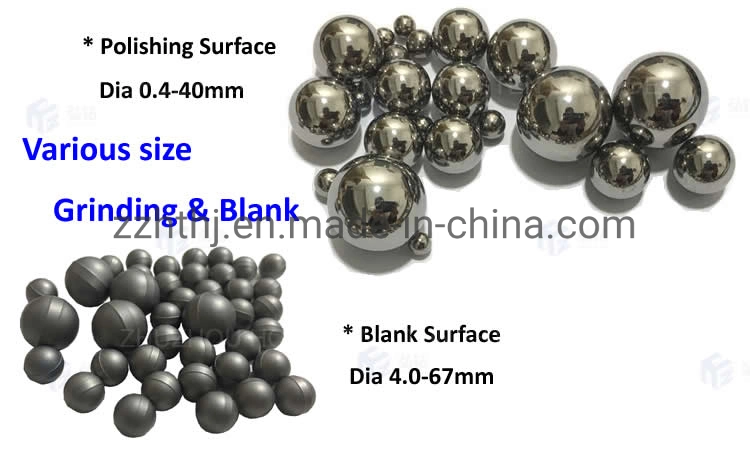

There are have three different types of carbide ball for choose.

Feature:

Tungsten carbide ball/TC alloy ball

High precision tungsten carbide balls /Tungsten alloy ball

Tungsten Carbide ball is mainly composed of high-hardness refractory metal carbide (WC, TiC) micron powder with

cobalt (Co) or nickel (Ni), molybdenum (Mo) as binder in vacuum furnace or Sintered powder metallurgy products in

hydrogen reduction furnace,

Nowadays common cemented carbides have YG, YN serials

- Grade 25

- Tungsten carbide (WC): 94%

- Cobalt (Co): 6%

- Hardness rockwell: R91 to 92.1

- Density: 14.95 gm/cc

- Transverse rupture strength: 400,000 to 410,000

- Porosity: A02, B00, C00 (Max.)

- Grain size: medium to coarse

G50, G100 and so on. The available grades and sizes are shown in the below table.

Application:

Tungsten carbide balls are used in applications requiring extreme hardness and resistance to wear and abrasion; and are

able to with stand hard shocks and impacts. Tungsten carbide balls are made with 6% nickel binder or 9% nickel binder.

Common applications include ball valves, flow meters, ball bearings, linear bearings, tungsten carbide grinding balls, and

ball screws.

Product Paramenters

Grade |

| Hardness (HRA) | Density (g/cm3) | T.R.S (MPa) | Description |

YG6 |

6%Co |

91 |

14.6-15.0 |

1600 | The highest wear resistance make this an excellent general purpose grade for use in pumps and valve |

YG8 |

8%Co |

89 |

14.4-14.8 |

1800 | With better shock resistance than YG6, This grade is typically used as a mining grade where thoughness and abrasion resistance are also important .it has also proven useful in bearing applications |

YG6x |

6%Co |

92 |

14.6-15 |

1850 | Sub-micro alloy, high hardness and wear resistance than YG6, little lower toughness than YG8, Used in parts where high wear resistance and high toughness are required. |

YG13 | 13%Co | 90.5 | 14.1-14.5 | 1950 | high toughness and hardness grade. |

YN6 |

6%Ni |

90 |

14.5-14.9 |

1450 | The highest hardness and wear resistance and corrosion resistance. Used in parts where corrosive condition in high temperature are required. |

YN8 |

8%Ni |

88 |

14.4-14.8 |

1650 | With higher hardness and wear resistance. Used in parts where shock resistance and corrosion are required. |

YN9 |

9%Ni |

88 |

14.4-14.8 |

1900 | With higher hardness and wear resistance. Used in parts where shock resistance and corrosion are required. |

YN12 |

12%Ni |

86 |

14.0-14.4 |

1800 | Higher toughness for impact load. Used in parts where better shcok and impact are required. |

Details Images

Company Profile

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located inthe hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized

in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications.

Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes,

Finished Products and Packaging to ensure high quality products output.

We mainly produce Tungsten Carbide Ball and Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles,

HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars, Rod, Strips, PDC substrate, Weld on teeth,

Bushings, Wire Drawing Dies, Heading Dies, Seal Ring, Nozzles, and other customized carbide products.

Product packaging

FAQ

Q1 : Are you Factory or trading company ?We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on