Basic Info.

Model NO.

SR608

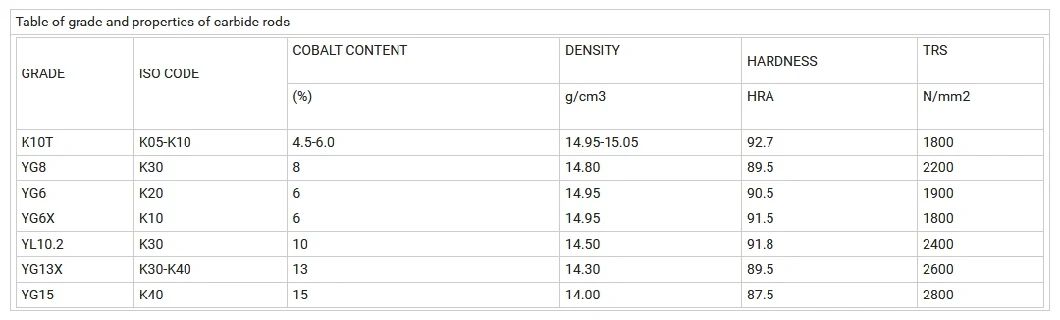

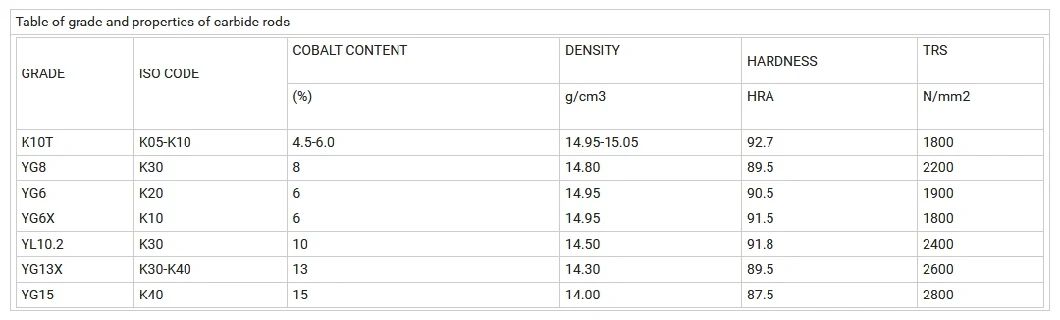

Carbide Grade

K05, K10, K15, K20, K40 etc

Surface Treatmen

Blank or Gound

Sinter

Hip Sintered

Chemical Composition

Wc+Cobalt, Ti, Ni, etc

Tolerance

H5/H6

Transport Package

Standard Packing

Specification

OD1 to OD60mm X L 330

Trademark

Sunrise

Origin

Zhuzhou Hunan China

HS Code

820900290

Production Capacity

5 Tons/Month

Product Description

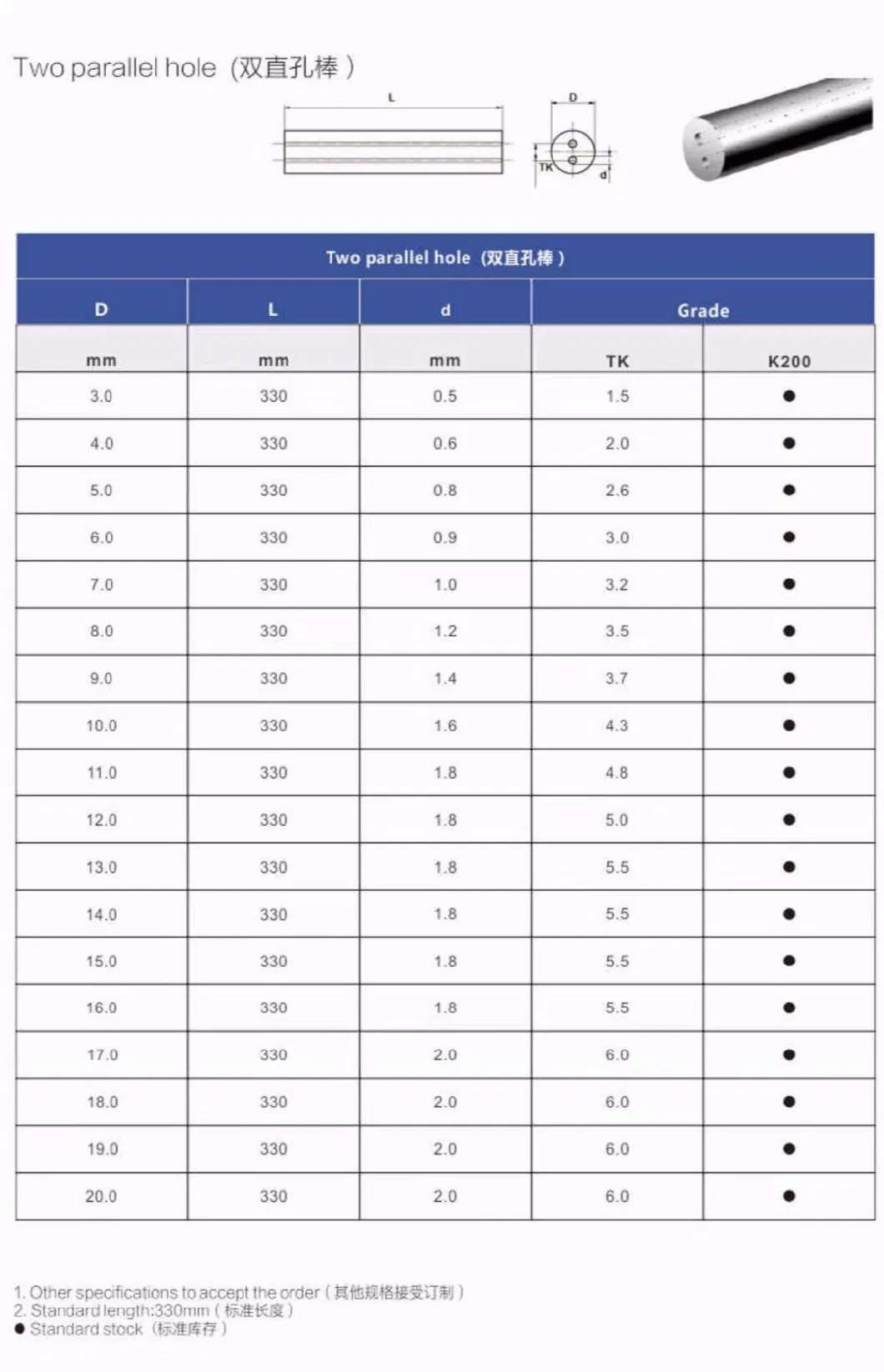

YL10.2 tungsten carbide double holes straight bar in grined h5 h6

Prodcuts Description

Ground & Unground tungsten carbide double holes straight rod with 330L

Application

Tungsten carbide rod with coolant hole has a wide range of application, such as producing finished cutting tools, such as twist drills, mills, reamers, taps and burrs etc., besides these, they are also widely applied to produce processing tools of making printed circuit boards (PCB), such as micro-drills, big-head drills and gravers etc.

Submicro Grain Size, with all HIP treatmemt

Made from extra-fine grain size (0.5~0.7μm) of tungsten carbide powders, TDC has developed series of sub-micro grades with HIP treatment for the different applications of solid carbide rod which all have good performance. Sintered blanks and H6 precision grinding are both available.

Advantage of Cemented Tungsten Bar Solid carbide Rod

1. Run-out and Roundness can be less than 5 micron(+0.005/-0.005mm);

2. Large stock & Fast Delivery & Good Price

3. A special Hot Isostatic Press (HIP) process provides quality improvement to the finished products to ensure meterial reliability

Various types are available:

1. solid carbide rods

2. single central hole rods

3. double parallel hole rods

4. double helical 30° 40° hole rods

5. chamfered rods

6. other special customized rods

Description of Tungsten carbide double holes straight rod

Zhuzhou Sunrise Hardmetal Tools Co., Limited is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process. All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Sunrise Hardmetal Tools Co., Limited is always insisting on the business idea of "integrity industry, brand business, quality development", and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them. We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

Prodcuts Description

Ground & Unground tungsten carbide double holes straight rod with 330L

Application

Tungsten carbide rod with coolant hole has a wide range of application, such as producing finished cutting tools, such as twist drills, mills, reamers, taps and burrs etc., besides these, they are also widely applied to produce processing tools of making printed circuit boards (PCB), such as micro-drills, big-head drills and gravers etc.

Submicro Grain Size, with all HIP treatmemt

Made from extra-fine grain size (0.5~0.7μm) of tungsten carbide powders, TDC has developed series of sub-micro grades with HIP treatment for the different applications of solid carbide rod which all have good performance. Sintered blanks and H6 precision grinding are both available.

Advantage of Cemented Tungsten Bar Solid carbide Rod

1. Run-out and Roundness can be less than 5 micron(+0.005/-0.005mm);

2. Large stock & Fast Delivery & Good Price

3. A special Hot Isostatic Press (HIP) process provides quality improvement to the finished products to ensure meterial reliability

Various types are available:

1. solid carbide rods

2. single central hole rods

3. double parallel hole rods

4. double helical 30° 40° hole rods

5. chamfered rods

6. other special customized rods

Description of Tungsten carbide double holes straight rod

|

Zhuzhou Sunrise Hardmetal Tools Co., Limited is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process. All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Sunrise Hardmetal Tools Co., Limited is always insisting on the business idea of "integrity industry, brand business, quality development", and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them. We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.