Basic Info.

Model NO.

B30 B40

Warranty

6 Month

Weight

Customized

Quality

ISO 9001

Use

Agriculturer Wear Parts

Grade

B30 B40 Yg15

Size

45X18X3, 45X18X7, 40X18X12, 30X30X7 etc

Key Word

Tungsten Carbide Weld on Tips

Transport Package

as Customer Demand

Specification

As customer

Trademark

HONGZUAN

Origin

Hunan, China

Production Capacity

10 Ton Per Month

Product Description

Products Description

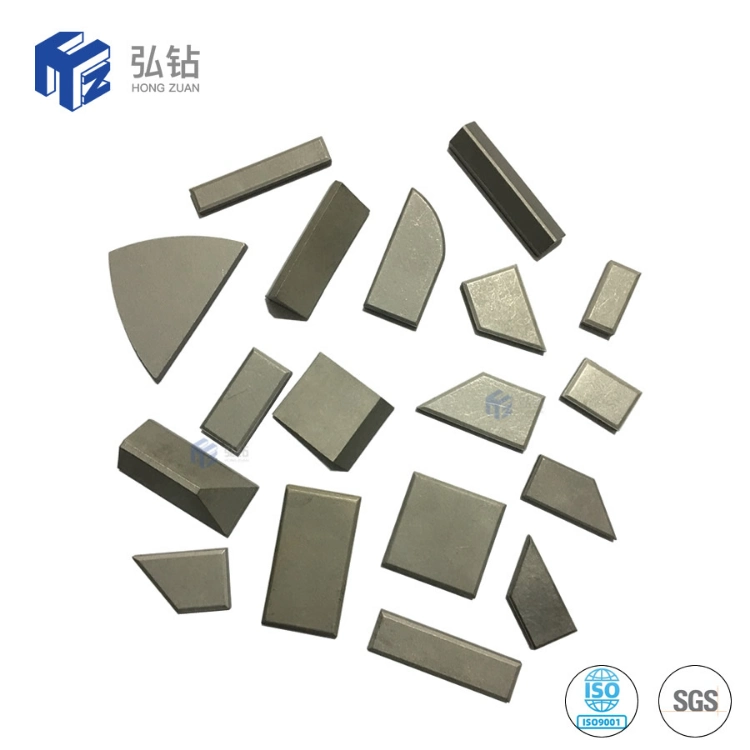

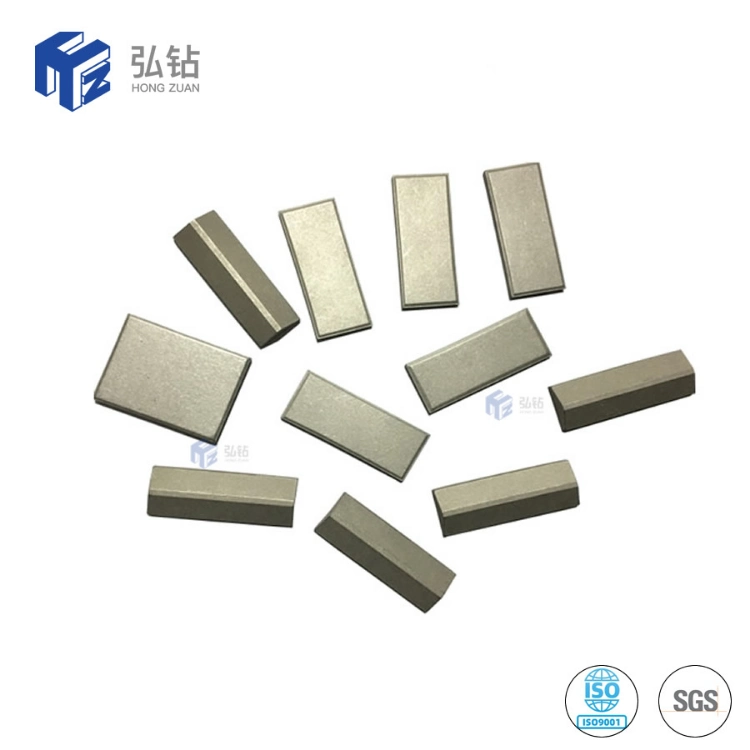

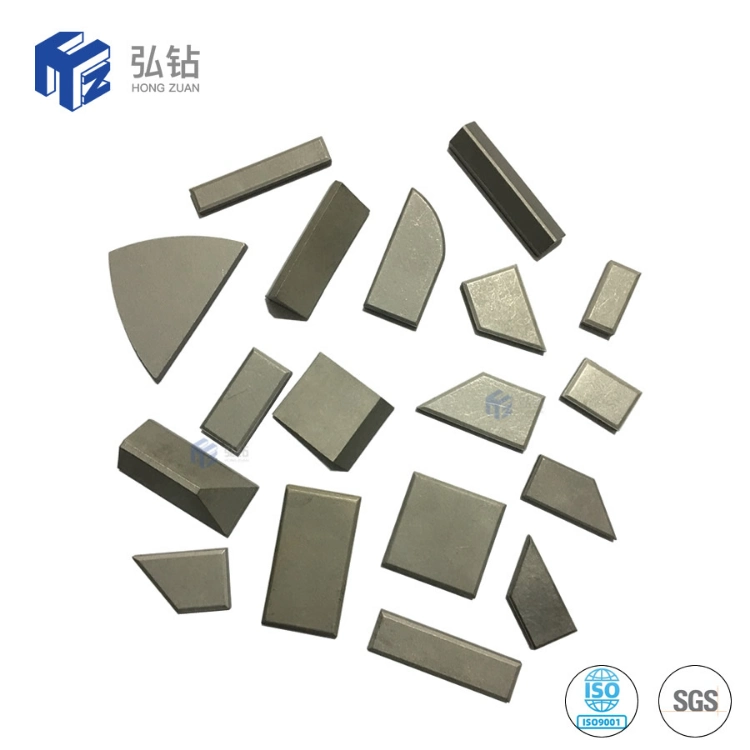

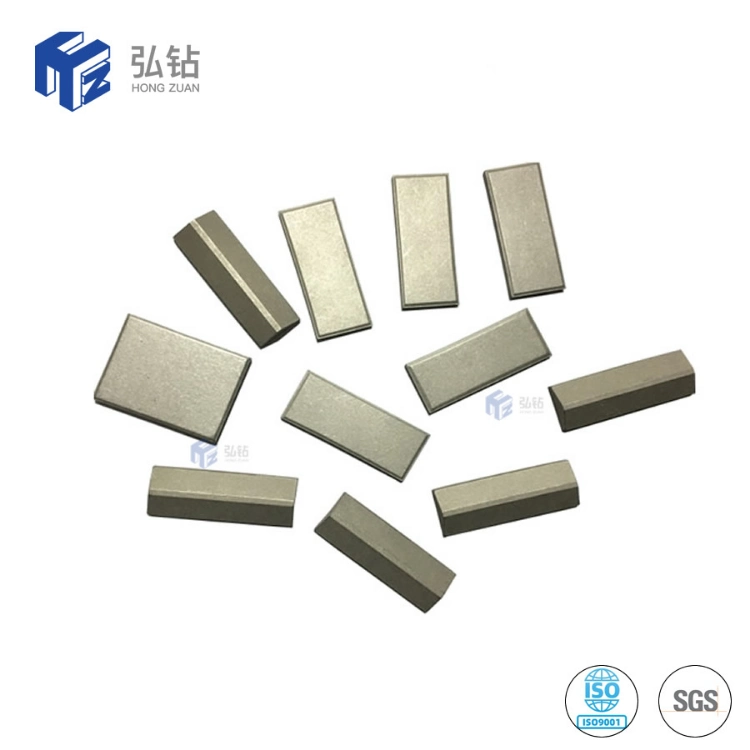

China Factory Tungsten Carbide Weld On Tips For Tillage Agriculture Machine

Feature:

Description of Tungsten Carbide teeth for agricultural machinery:

*Carbide plate for the tillage , cultivator , ploughs the best grade NO is YG11,YG8C,YG9C, YG15 B30,B40 etc

As some agricultural wear parts have to work in severe environment,so just casting with high strength is not enough,

to protect the castings from quick worn,this grade No. will greatly increase the serving life. We are producing carbide

agricultural tips according to customer's drawings.

*We can produce any type and size carbide plate, tile,teeth for the agriculture tool parts.

Application for Side band , Rumpstad, Tine Fit , Cultivator , Tillages. Shredder Knives etc.

*All goods we export to European Countries, Austria, France. UK, German, Poland, Netherlands. Czech.

*Our factory got so advantage for price and quality , delivery time.

*So welcome any factory who produce these agriculture tool parts.

Our products range of agriculture wear parts:

Power harrow tines

Subsoiler points and wings

Plough points and wings

Cultivator points

Bed tiller tines

Beet harvester turbine tines

Beet harvester shares

Sugar cane harvester base cutters

All scrapers

Behind regular tungsten

The sides of subsoiler legs

The sides of cultivator legs

The front of subsoiler shins

Straw rake tines

Many types of drill coulters Manure spreader beaters

Our advantages of Tungsten Carbide teeth for agricultural machinery:

1. Use 100% tungsten carbide raw material

2. ISO 9001 Certification

3. with 20 years experience in R & D and manufacturing.

4. Advanced technology and equipment , automatic pressing, HIP sintering, and precision grinding.

5. We accept OEM manufacturing and produce on your design.

Grade recommend

*Our factory got so advantage for price and quality , delivery time.

*So welcome any factory who produce these agriculture tool parts.

Our products range of agriculture wear parts:

Power harrow tines

Subsoiler points and wings

Plough points and wings

Cultivator points

Bed tiller tines

Beet harvester turbine tines

Beet harvester shares

Sugar cane harvester base cutters

All scrapers

Behind regular tungsten

The sides of subsoiler legs

The sides of cultivator legs

The front of subsoiler shins

Straw rake tines

Many types of drill coulters Manure spreader beaters

Our advantages of Tungsten Carbide teeth for agricultural machinery:

1. Use 100% tungsten carbide raw material

2. ISO 9001 Certification

3. with 20 years experience in R & D and manufacturing.

4. Advanced technology and equipment , automatic pressing, HIP sintering, and precision grinding.

5. We accept OEM manufacturing and produce on your design.

Grade recommend

| Grade No. | Density (g/cm³) | Hardness (HRA) | T·R·S (MPa) | Application Recommended |

| YG6 | 15.80 | 89.5 | 1700 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG8 | 14.70 | 88.5 | 2300 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG15 | 14.00 | 86.5 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. |

| YG20 | 13.40-13.70 | 85.0 | 2254 | Mainly for the stamping dies used in the conditions of heavy impact load and large strees |

Carbide Agriculture plate Application:

Company Profile

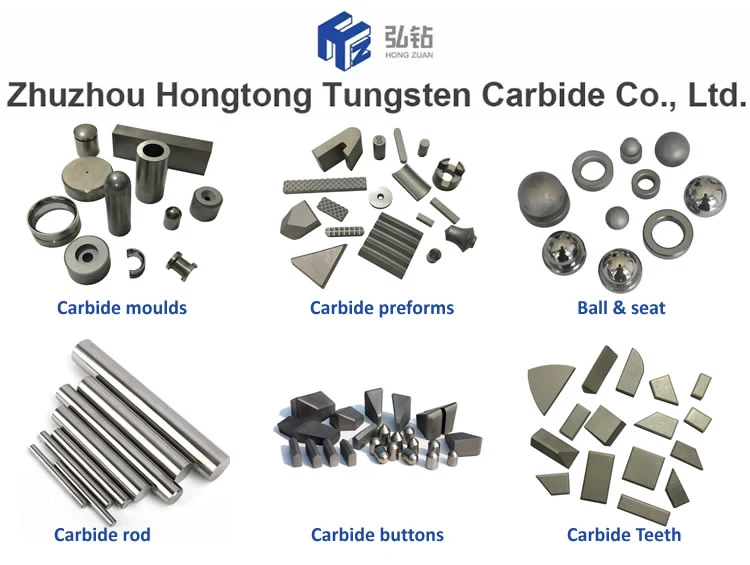

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located in

ZhuZhou HongTong Tungsten Carbide Co., Ltd.,specialized in production carbide products more than 20 years and located inthe hometown of tungsten carbide in China. We can manufacture all kind of tungsten carbide products. Our products are utilized

in industrial, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction applications.

Now we are exporting to 46 countries. including USA, Russian , India , Italy, Poland ,France,Brazil etc .

We have a professional QC team follow to the System of ISO9001:2015, Covering the Raw Materials Incoming, Production Processes,

Finished Products and Packaging to ensure high quality products output.

We mainly produce Tungsten Carbide Ball and Seat, Agriculture wear parts plates, Carbide tips, Carbide tiles,

HPGR Stud pins, Brazed Inserts, Gripper Pads, Buttons, VSI Bars, Rod, Strips, PDC substrate, Weld on teeth,

Bushings, Wire Drawing Dies, Heading Dies, Seal Ring, Nozzles, and other customized carbide products.

Product packaging

FAQ

Q1 : Are you Factory or trading company ?We are Factory with 20 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning,

stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy? 1. Fill your Order List in our online

Inquiry System (Also you can directly contact our salesperson by E-mail / Skype / Whats App) 2. We will make a feedback to you ASAP after receive your order list.

Q7: What's your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on