- Overview

- Product Description

- Detailed Photos

- Company Profile

- FAQ

Basic Info.

Model NO.

YN7

Packing

Standard Carton Box

Advantage

High Wear Resistance

Transport Package

in Carton Wraped by Waterproof Paper Each.

Specification

50*10*3mm customized

Origin

China

HS Code

8207909000

Production Capacity

200

Product Description

cemented tungsten carbide plate for making blade

Product Paramenters

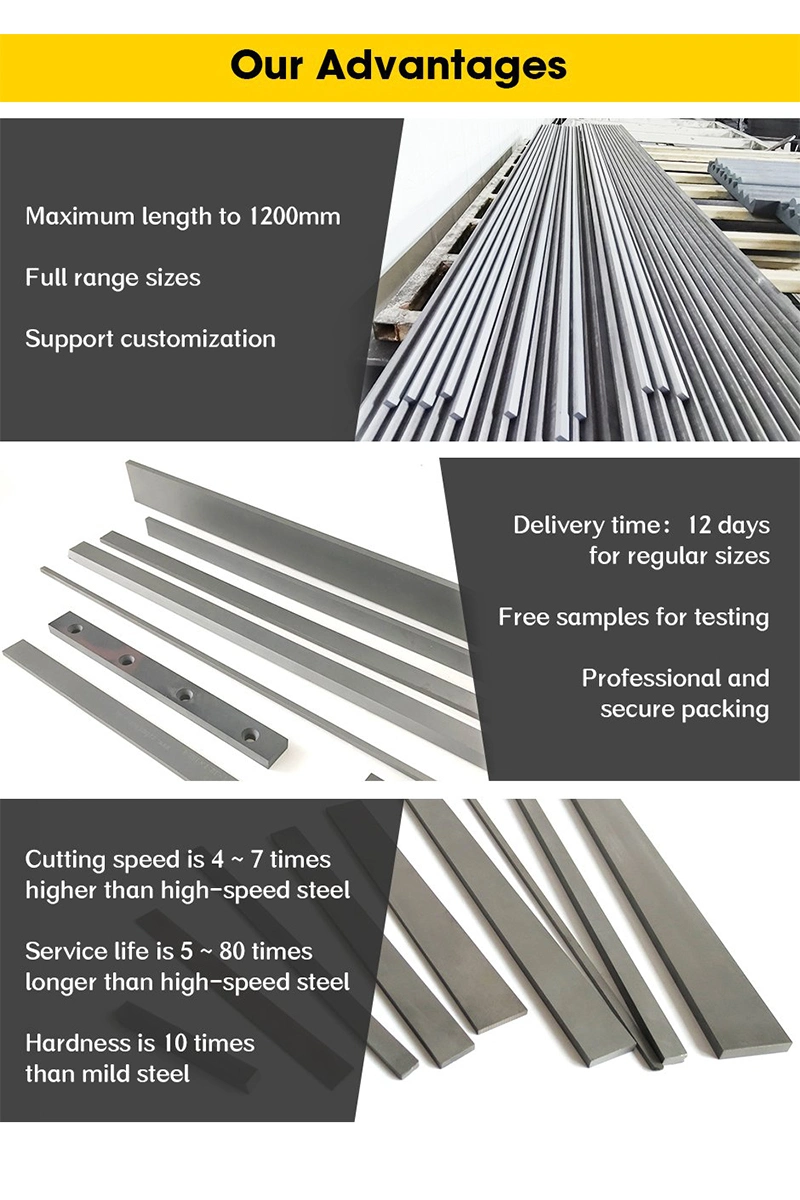

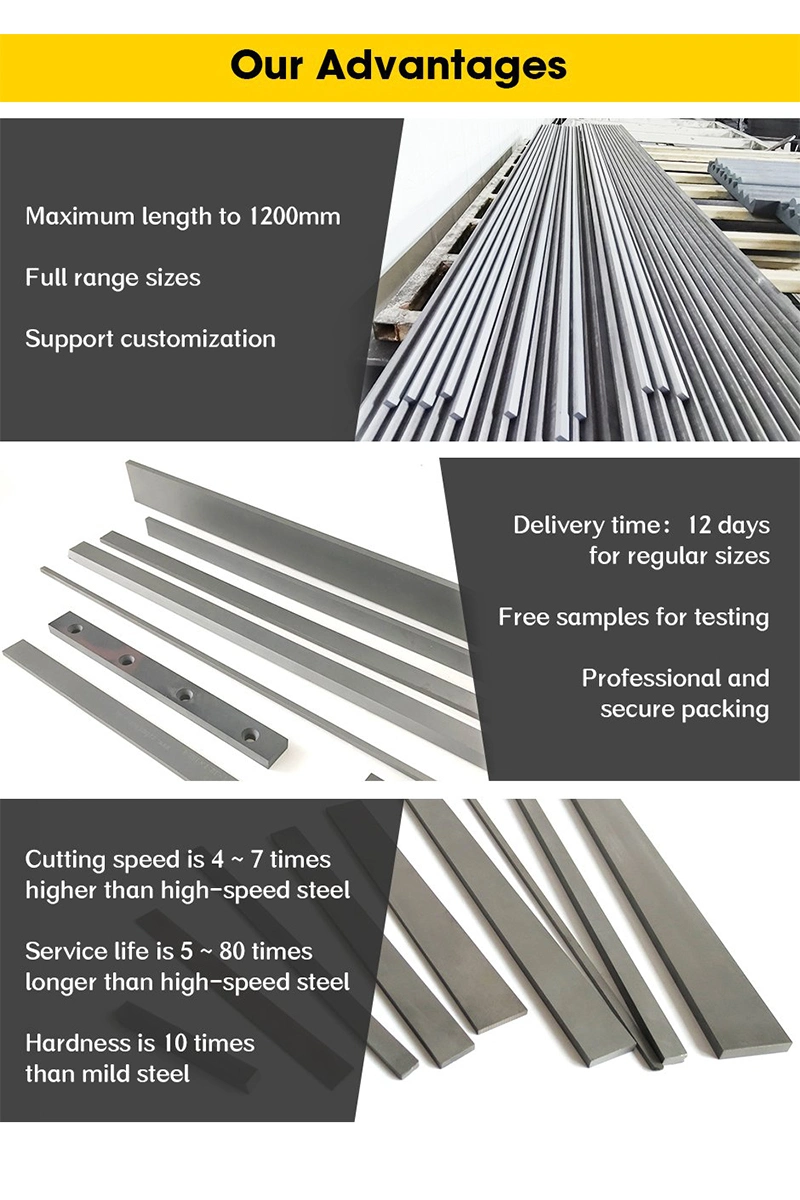

Winway Group is a professional manufacture of cemented carbide factory based on hebei China Since 1989. We specialize in researching, designing and manufacture of Tungsten carbide products. Such as tungsten carbide tips, tungsten carbide rods, tungsten carbide bar, tungsten carbide strips, tungsten carbide buttons, CNC inserts, mineral tools, wear resistance products and other non-standard carbide products.

With up-to-date production line, advanced equipment from Switzerland, strict quality control system from raw material to qualified products. Which made our products Stability, Practicality, Reliability. Our products are welcomed by customers from over 30 countries in Europe, North America, South America, Australia, Africa and south Asia,

OEM Service: Helping to create your own brand with Customized package.

Steady quality, good price, prompt shipment and professional service

Sample are available.

Faithfully desire to develop mutual benefit business relation with all customers from all over the world.

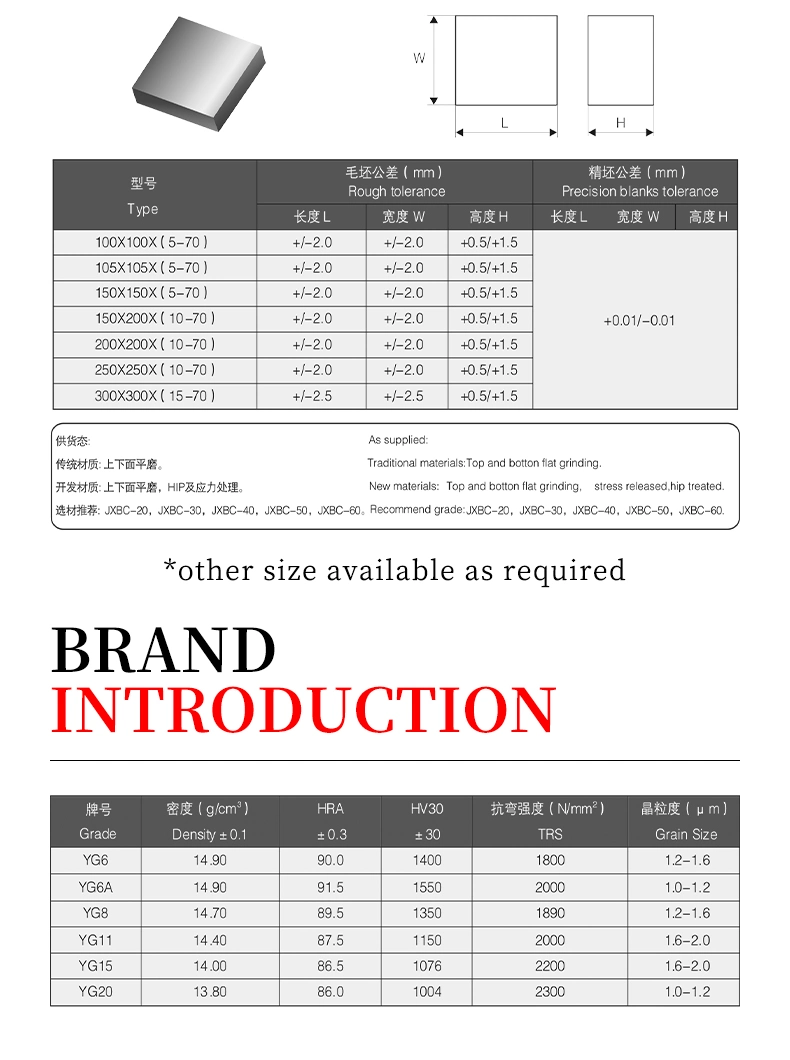

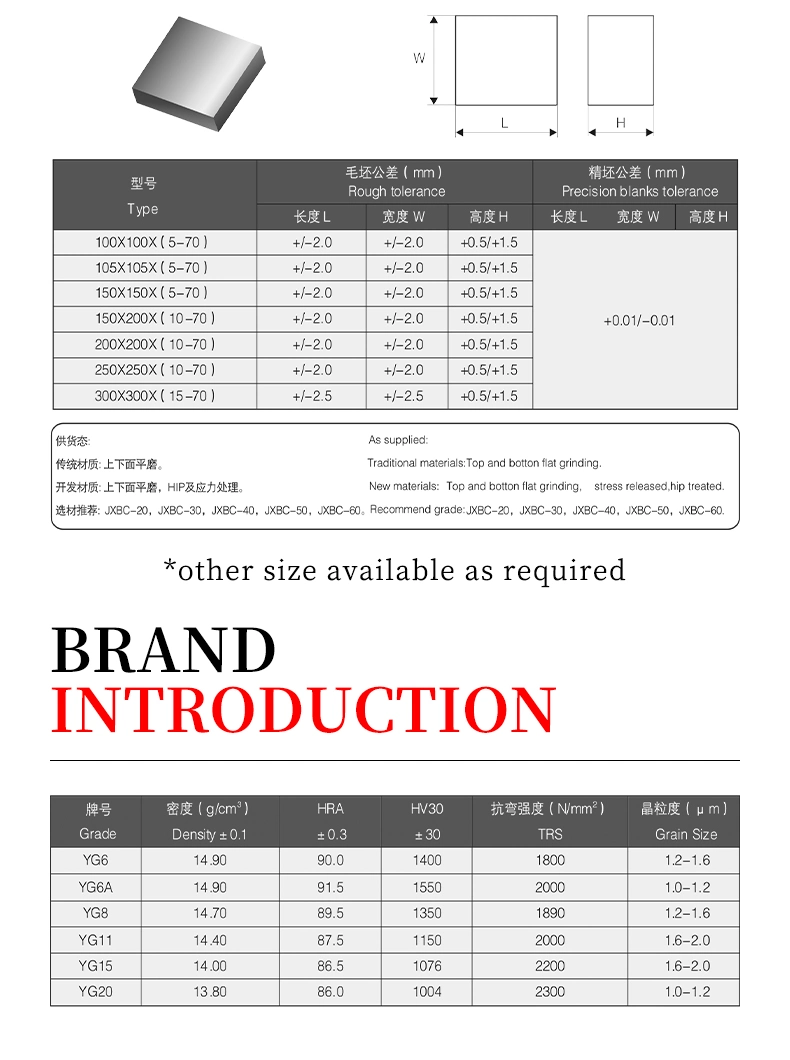

| Product name | Materials |

| tungsten carbide plate/flat bar blanks | tungsten carbide, cobalt |

| Product features | |

| Tungsten carbide wear-resistant parts cover a wide range, from small ballpoint pen tips to large stamping machines, wire drawing dies, or rolling mills used in the steel industry, where wear-resistant parts can be produced using tungsten carbide. In pumps, compressors, and mixers, tungsten carbide sealing rings are used as mechanical sealing surfaces. Due to the strong wear resistance of tungsten carbide, these component products also have super strong wear resistance. | |

Product Paramenters

| Grade | Grain size | Cobalt content (%) | Hardness (HRA) | Density (g/cm³) | TRS (N/mm²) |

| HU20 | Submicron | 10 | 91.8 | 14.4 | 3500 |

| Applicable to metal sheets stamping with small blanking load,with high wear resistance and long mould application life,mainly for making small punches. | |||||

| HM24C | Coarse | 12 | 88.1 | 14.31 | 3200 |

| Applicable to all kinds of metal sheet stamping, medium coarse grain size, high toughness,highly optimized for general use and wide application range. | |||||

| HM30AX | Ultrafine | 15 | 91 | 13.85 | 4000 |

| Applicable for stainless steel and copper alloy stamping.High hardness and fine toughness for semi-conductor and electronics stamping. | |||||

| HM30 | Medium | 15 | 86.5 | 14 | 3000 |

| High toughness cold heading die | |||||

| HM40C | Coarse | 20 | 83.5 | 13.5 | 2600 |

| High impact resistance forging die | |||||

| YN15 | Medium | 15(Ni) | 85.3 | 14.19 | 2700 |

| Non-magnetic properties,for iron rivet stamping and magnetic material forming cavities. | |||||

| YN7 | Medium | 7(Ni) | 92.0 | 14.91 | 2300 |

| Non-magnetic properties,for copper rivet, iron rivet stamping and blanking die making. | |||||

| Cemented Carbide Plates(unit:mm) | |||||

| L×W | Length & Width Tolerance | H | Height Tolerance |

| 100x100 | +0/+5 | 3~90 | +0.0/+0.5 |

| 100x150 | +0/+5 | 3~65 | +0.0/+0.5 |

| 150x150 | +0/+5 | 3~60 | +0/+1 |

| 200x200 | +0/+5 | 3~60 | +0/+1 |

| 250x250 | +0/+5 | 10~50 | +0/+1 |

| 300x300 | +0/+5 | 10~50 | +0/+1 |

| Remark:Dimension customized available | |||

Winway Group is a professional manufacture of cemented carbide factory based on hebei China Since 1989. We specialize in researching, designing and manufacture of Tungsten carbide products. Such as tungsten carbide tips, tungsten carbide rods, tungsten carbide bar, tungsten carbide strips, tungsten carbide buttons, CNC inserts, mineral tools, wear resistance products and other non-standard carbide products.

With up-to-date production line, advanced equipment from Switzerland, strict quality control system from raw material to qualified products. Which made our products Stability, Practicality, Reliability. Our products are welcomed by customers from over 30 countries in Europe, North America, South America, Australia, Africa and south Asia,

OEM Service: Helping to create your own brand with Customized package.

Steady quality, good price, prompt shipment and professional service

Sample are available.

Faithfully desire to develop mutual benefit business relation with all customers from all over the world.

1. Are you trading company or manufacturer ?

We are factory, mainly product tungsten carbide product.

2. How can we guarantee quality?

2. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment

3. How long is your delivery time?

3. How long is your delivery time?

Generally it is 3~5 days if the goods are in stock; or it is 7-25 days if the goods are not in stock, depending on order quantity.

4. Do you provide samples?

4. Do you provide samples?

Is it free or extra? Generally we don't provide free samples. But we can deduct sample cost from your

bulk orders.

5. What is your payment terms and method?

bulk orders.

5. What is your payment terms and method?

Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before

shippment. We accept T/T, L/C, Alipay, PayPal, Western Union Wechat and so on.

shippment. We accept T/T, L/C, Alipay, PayPal, Western Union Wechat and so on.