Basic Info.

Model NO.

Customized

Product Name

Tungsten Carbide Saw Blade

Chemical Composition

Co, W, Customized

Surface Quality

Ground or Polishing, Coated

Grade

K30

Delivery

About 25-30 Days

OEM

Offered

Transport Package

Customized Package, Neutral Packing Available

Specification

ISO9001: 2000

Trademark

FOTMA

Origin

P. R. China

HS Code

8113009090

Production Capacity

500t/Year

Product Description

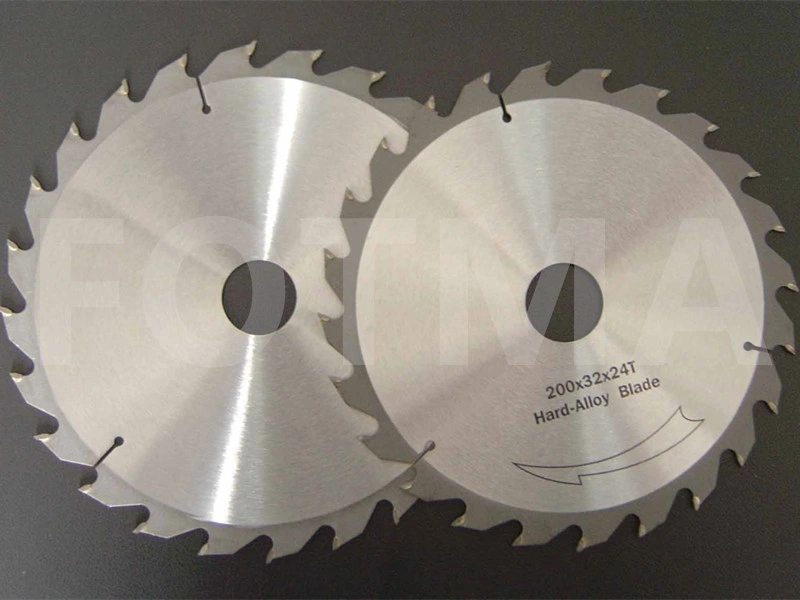

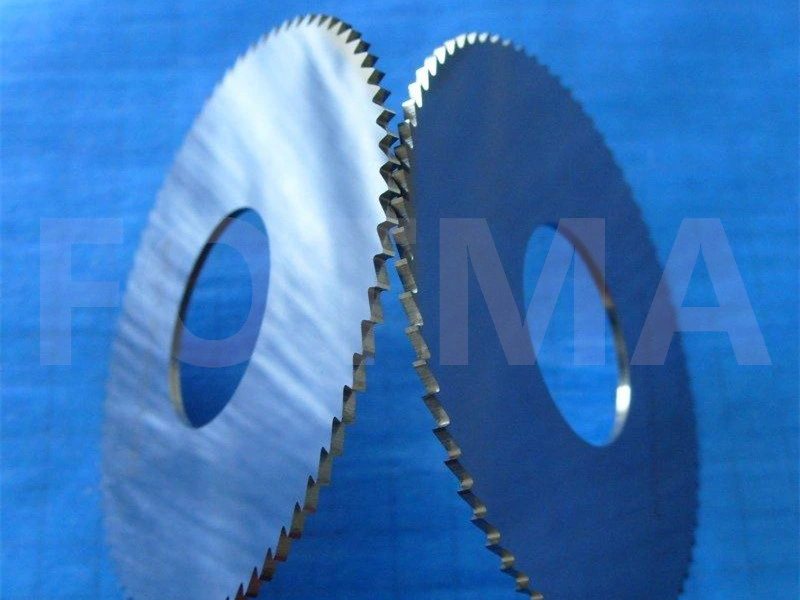

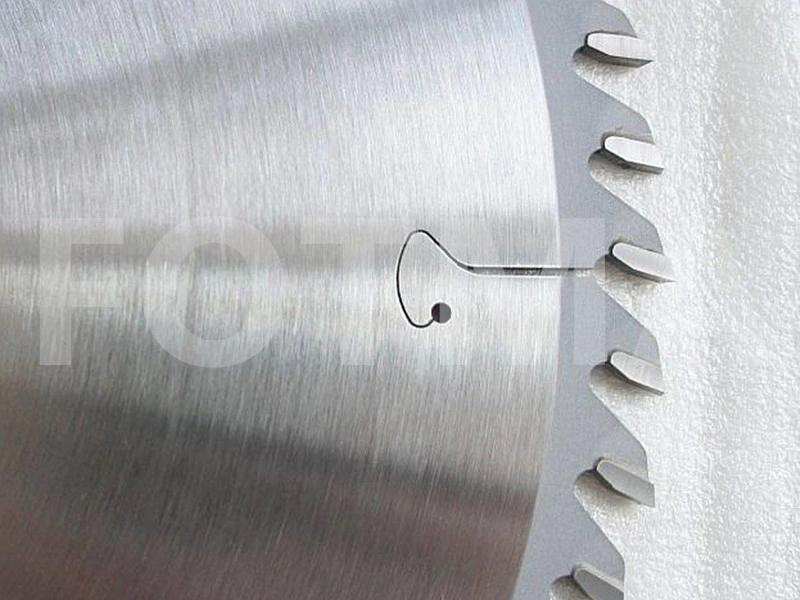

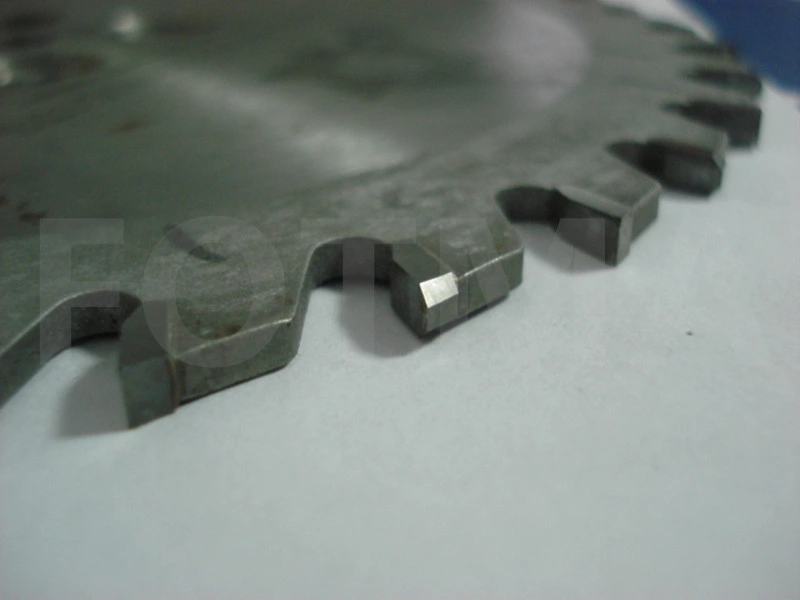

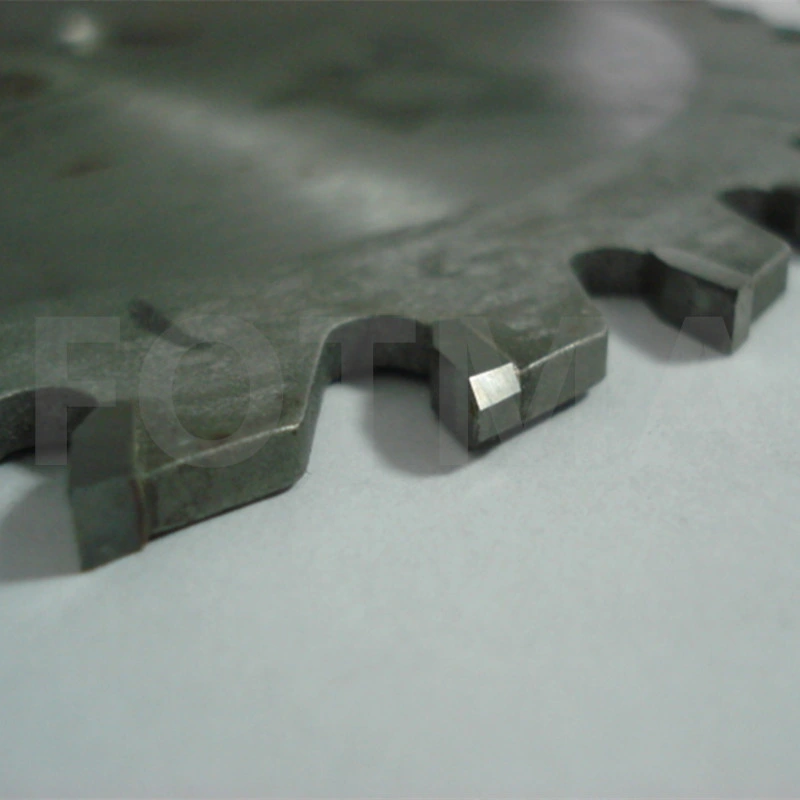

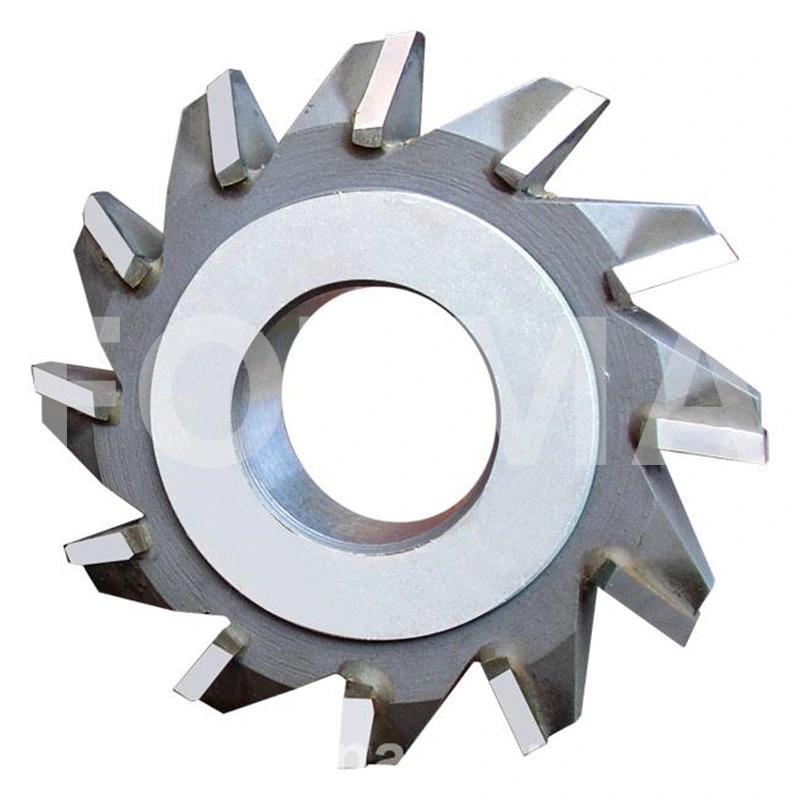

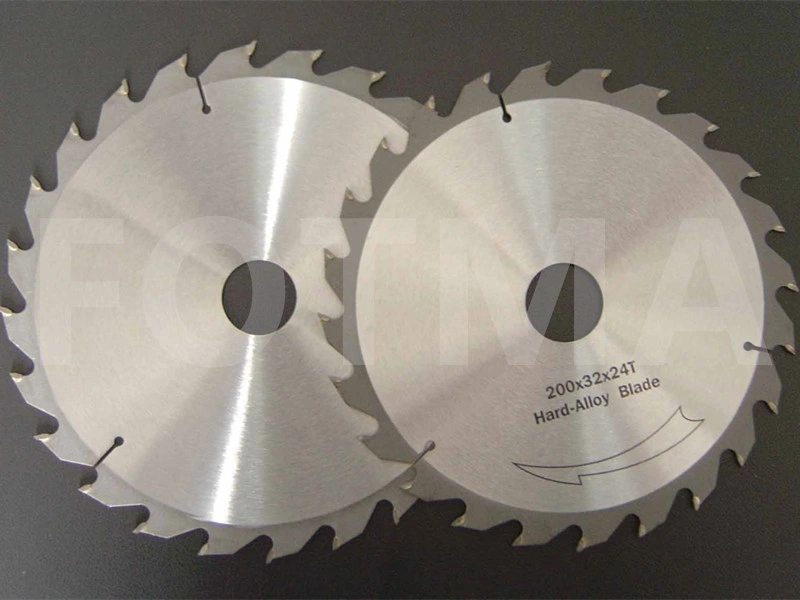

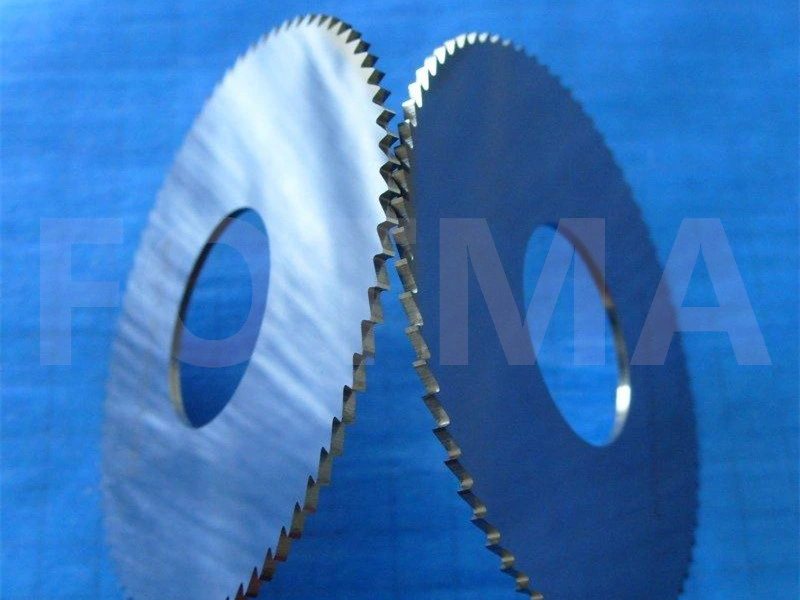

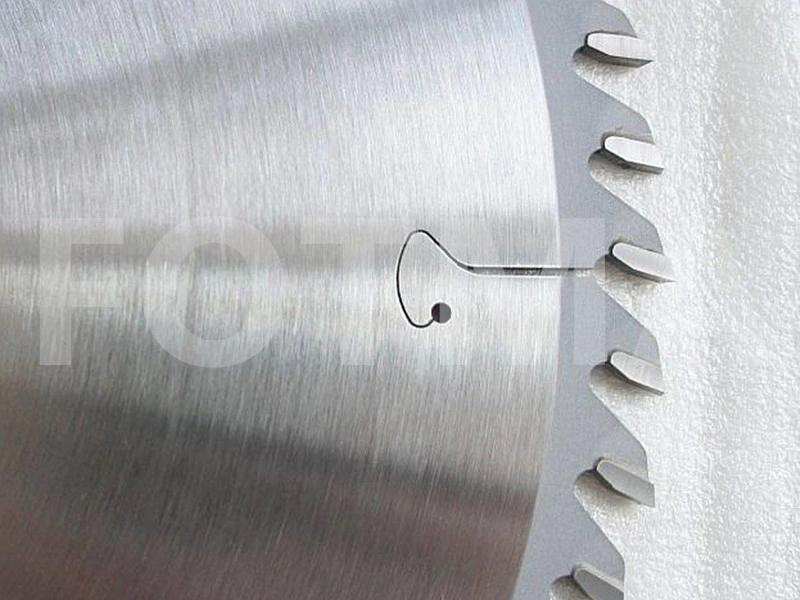

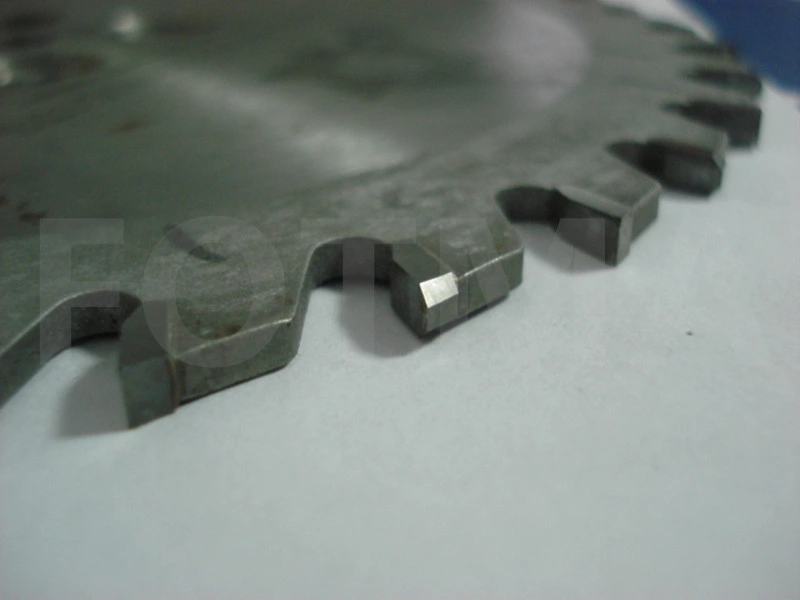

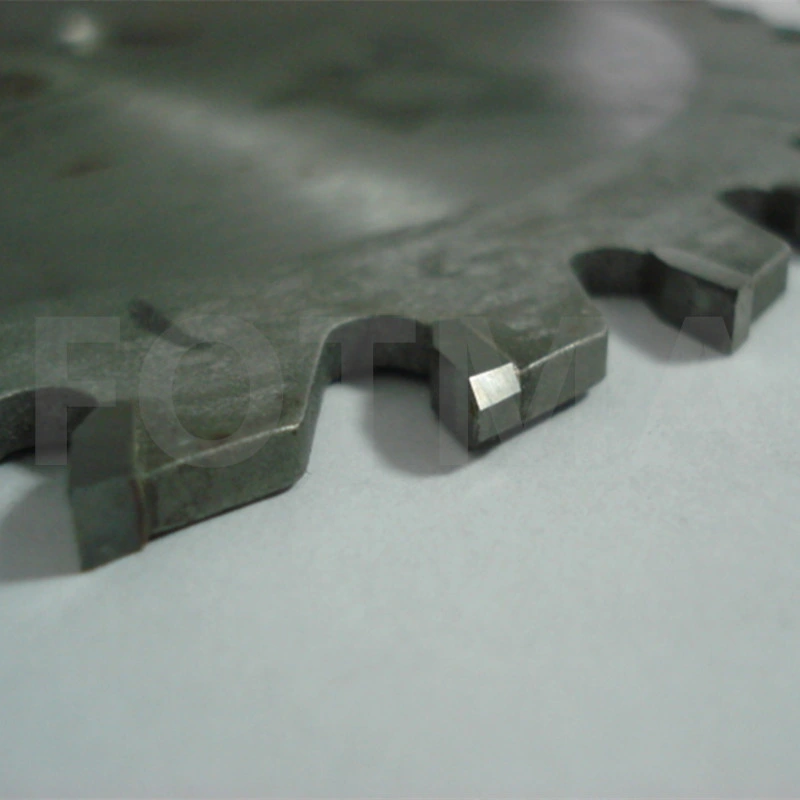

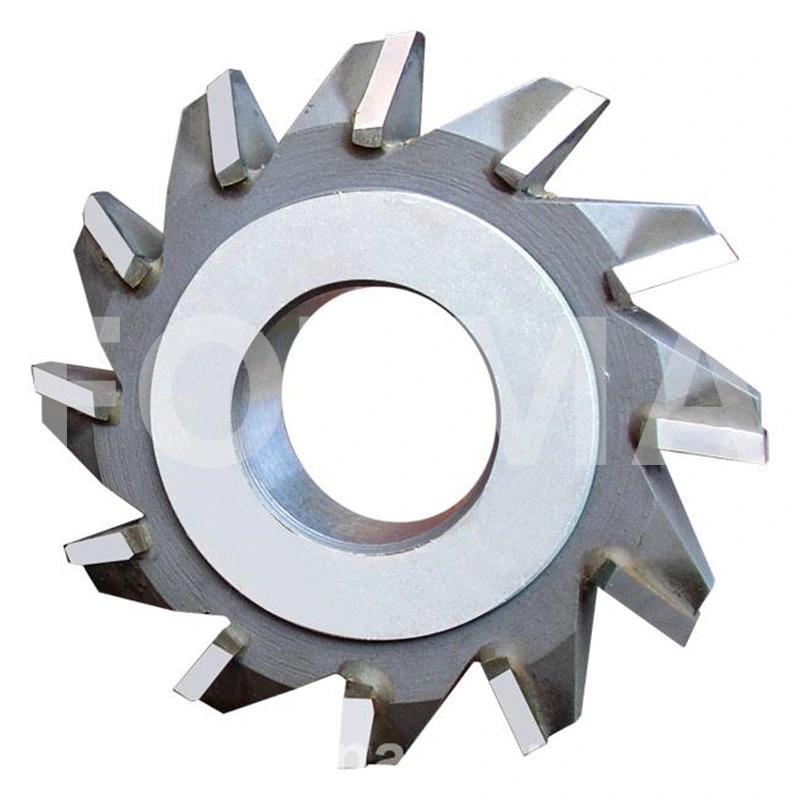

Cemented Tungsten Carbide Saw Blade Welding Tipped Cutting Saw Blade

Advantages of our carbide products:

1. Stable and reliable quality

2. Made from 100% virgin material

3. All products go through in-process and final inspection

4. Free online technical service available

5. Produced with advanced equipments and process

6. Sample available

Tungsten Carbide tools have many applications based on the industries that use carbide equipment and other hard materials like diamonds.

Tungsten carbide is especially used in sharpening of blades used in industrial applications. These tungsten carbide tools are used to improve versatility and productivity when sectioning plastic. During these cryo applications, the tungsten carbide tool is embedded in a holder made of steel. The blades are consistent and can survive through thousands of applications eliminating the need for frequent changes.

Our company has in its possession an advanced production line for manufacturing dies and moulds and a production line for post machined cemented carbide products. We can also supply tailor-made products of various specifications based on the requirements of our customers.

Our main products include: Cemented carbide drills, cutting cutters, mining tools, drawing dies, carbide strip, rods and so on. Skillful workers and advanced machines can make every of your size possible. Diffrent grade are available too, such as K01, K05, K10, K15, K20, K30, P20, P40 etc.

Grade List for Tungsten Carbide Tools:

Product Show:

Advantages of our carbide products:

1. Stable and reliable quality

2. Made from 100% virgin material

3. All products go through in-process and final inspection

4. Free online technical service available

5. Produced with advanced equipments and process

6. Sample available

Tungsten Carbide tools have many applications based on the industries that use carbide equipment and other hard materials like diamonds.

Tungsten carbide is especially used in sharpening of blades used in industrial applications. These tungsten carbide tools are used to improve versatility and productivity when sectioning plastic. During these cryo applications, the tungsten carbide tool is embedded in a holder made of steel. The blades are consistent and can survive through thousands of applications eliminating the need for frequent changes.

Our company has in its possession an advanced production line for manufacturing dies and moulds and a production line for post machined cemented carbide products. We can also supply tailor-made products of various specifications based on the requirements of our customers.

Our main products include: Cemented carbide drills, cutting cutters, mining tools, drawing dies, carbide strip, rods and so on. Skillful workers and advanced machines can make every of your size possible. Diffrent grade are available too, such as K01, K05, K10, K15, K20, K30, P20, P40 etc.

Grade List for Tungsten Carbide Tools:

Grade | Density g/cm3 | Hardness HRA | Strength N/mm2 Min. | Applications | ISO grade |

YG6X | 14.8-15 | 91.7-93 | 1600 | High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast iron | K10(ANSI C-2) |

YT5 | 12.85-13.05 | 89.5-91 | 1700 | Excellent in strength, impact resistance and resistance to thermal shock; Rough turning, rough planning and semi planning of Carbon steel and alloy steel | P30(ANSI:C-5) |

YT15 | 11.2-11.4 | 92-93 | 1350 | Good wear resistance, with normal impact resistance; Semi finishing and finishing steel, cast steel, alloy steel. | P10 |

YT14 | 11.3-11.6 | 91.3-92.3 | 1450 | High in impact resistance and strength; Semi roughing and semi finishing of steel, cast steel and alloy steel. | P20-P30 |

YT535 | 12.6-12.8 | 90-91.5 | 1760 | High wear resistance and red hardness, high strength in use. For continuous rough turning and milling of cast or forged steel. | P30 |

ZP25 | 12.5-12.7 | 91.4-92.3 | 1750 | Fine in wear resistance and toughness; Rough turning, milling, planning and depth drilling of carbon steel, cast steel, manganese steel and alloy steel. | P20-P30 |

ZP35 | 12.6-12.8 | 90.5-91.5 | 1770 | A versatile grade, high in red hardness, strength and resistance to impact and thermal shocking. Roughing and strong cutting of steel and cast steel. | P30-P40 |

YG6 | 14.8-15 | 90-92 | 1650 | Good wear resistance, resistance to impact and thermal shocking. Semi finishing and finishing of cast iron, nonferrous metal, alloy and nonmetallic material. | K15-K20 |

YW1 | 13.25-13.5 | 92-93.2 | 1420 | A versatile grade, good in red hardness, able to endure normalimpact load; machining of refractory steel, high manganese steel, stainless steel, also suitable to the ormal steel and cast iron. | M10/P10 |

YW2 | 13.15-13.35 | 91.3-92.3 | 1600 | Good wear resistance and high strength, able to endure high impact load; Roughing, semi finishing of refractory steel, high manganese steel, stainless steel and high alloy steel, also suitable to the normal steel and cast iron. | M20/P20-30 |

ZM15 | 13.8-14.0 | 91-92.2 | 1720 | Good Red Hardness, high strength in use, capable of resisting high impact load. Finishing and semi-finishing of refractory steel, high manganese steel, and austenitic stainless steel, also suitable for Cast Iron. | M15 |

ZM30 | 13.5-13.7 | 90-91.5 | 1890 | High strength in use, capable of resisting high impact load. Roughing and semi-finishing of refractory steel, high manganese steel, stainless steel, etc. | M30 |

ZK10UF | 14.75-14.95 | 92.6-93.6 | 1690 | Fine-grained alloy, good wear resistance and high strength. Semi-finishing and finishing of cast iron and nonferrous metals. It is the unique material for making of solid carbide tools for holing. | K10-K15 |

ZK30UF | 14.3-14.55 | 91.2-92.2 | 2180 | Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Machining of cast irons, nonferrous metals and non-metallic materials. It is the unique material of solid carbide tools for holing. | K30 |

Note: The specification dates just the standard, the actual specification for the products are much better than the standard. | |||||

Suggestion: We would like to recommend suitable grade depending on your machining materials. | |||||

Product Show: