Basic Info.

Model NO.

G30 Tungsten carbide cold heading dies

Driving Motor Type

Hybrid

Mold Cavity Technology

CNC Milling

Milling Speed

High Speed

Parts Detection Method

Geometric Detection

Grade

Yg15, Yg20c, Yg22c, Yg25c

Usage

Wear Parts and to Make Nails

Tolerance

Blanks, Semi-Finish, Finishing

Commodity

Cemented Carbide Cold Forging Dies

Transport Package

in Cartons, by Air or Express

Specification

standard or customized

Trademark

UBT

Origin

China

HS Code

848049000

Production Capacity

60 Tons/Month

Product Description

G30 Tungsten carbide cold heading dies

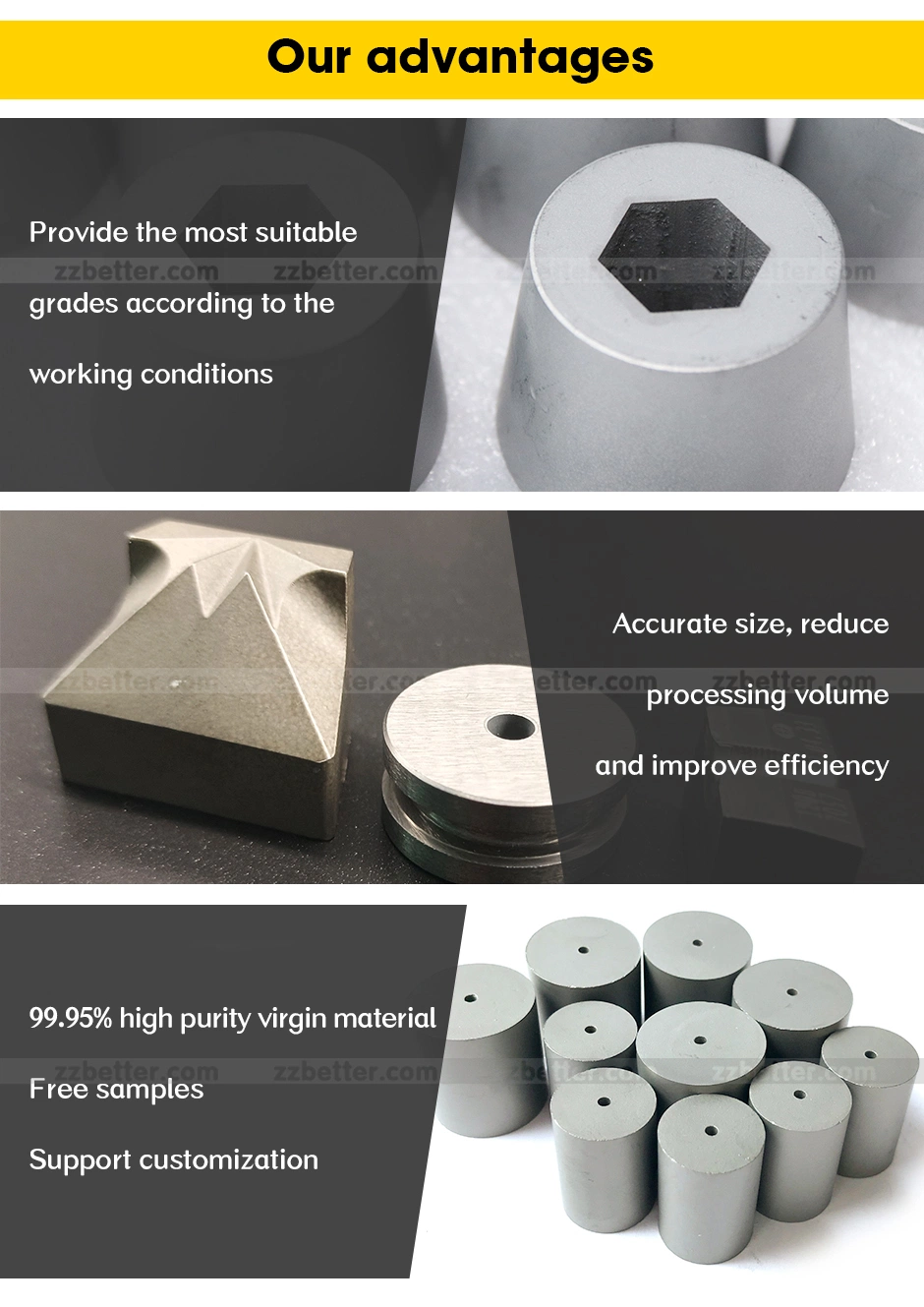

Tungsten Carbide cold heading dies have high impact resistance, toughness and wear resistance. They are mainly used in processing some hard metal tools, especially for bolts, rivets, heading of screws, nibs nuts, and so on.

Grade recommanded:

| Grade | ISO | Performance | Performance&application recommended | ||

| Density | Hardness | TRS | |||

| G/Cm3 | HRA | N/mm2 | |||

| YG11C | G20 | 14.4 | 88.5 | 2600 | Forming or stamping dies for metal powders and nonmental powders. |

| YG15 | G30 | 14.0 | 87.5 | 2800 | For punching, stamping, forging tools under large stress. |

| YG18C | G30 | 13.7 | 84.5 | 3100 | Impact resistance forging dies,hot-press forging dies and rollers. |

| YG20 | G40 | 13.5 | 85.5 | 3200 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, screws, screw caps. |

| YG20C | G40 | 13.5 | 83.5 | 3300 | Dies for wear resistant or impact resistant application. |

| YG22C | G40 | 13.3 | 83 | 3500 | Nut forming dies and high impact resistance forging dies. |

| YG25C | G50 | 13.1 | 82.5 | 3600 | Stainless bolt header dies and rollers |

Please contact us for more details!

Don't hesitate, try our products, you will win the market!