Basic Info.

Model NO.

G5 grade cemented carbide heading dies

Driving Motor Type

Hybrid

Mold Cavity Technology

CNC Milling

Milling Speed

Normal Speed

Parts Detection Method

Measurement of Three Axis NC

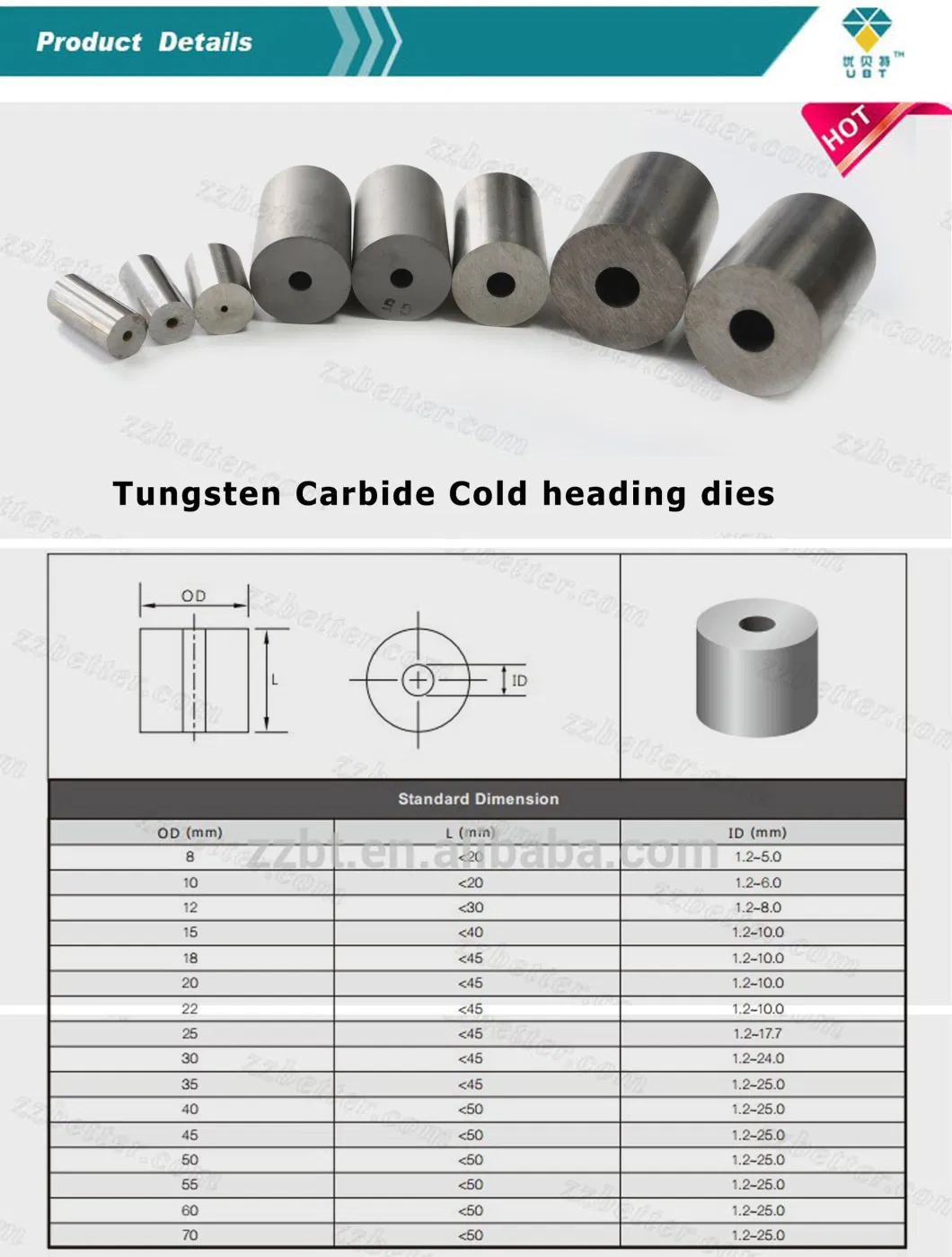

Product Name

G5 Grade Cemented Carbide Heading Dies

Other Name

Tungsten Carbide Forging Dies

Key Words

Carbide Dies, Carbide Mold

Applciation 1

to Be Used as Wear Parts

Applciation 2

to Be Used as Mold to Make Nails

Field Can Be Used 1

Fastener Industry

Field Can Be Used 2

Auto Industry

Field Can Be Used 3

Where High Enduribity Requried

Transport Package

in Carton

Specification

customized

Trademark

UBT

Origin

China

Production Capacity

40tons/Month

Product Description

G5 grade cemented carbide heading dies

Commonly Grades used for tungsten carbide heading dies

| Carbide punching and impacting dies | |||||||

| Grade | Performance | Performance&application recommended | |||||

| Density | Hardness | Bend Strength | |||||

| G/Cm3 | HRA | N/mm2 | |||||

| YG11 | 14.4 | 88.5 | 2600 | Forming or stamping dies for metal powders and nonmental powders. | |||

| YG15 | 14 | 87.5 | 2800 | For fabricating drawing dies of steel tubesand rods under high | |||

| compressibility ratio;punching,stamping,forging tools under large stress. | |||||||

| YG20 | 13.5 | 85.5 | 3200 | For fabricating of stamping dies for watch parts, spring plates of musical | |||

| instruments, battery jars,small sized steel balls,screws,screw caps. | |||||||

| YG16C | 13.9 | 85.5 | 2900 | Impact resistance, hot&forging dies etc. | |||

| YG18C | 13.7 | 84.5 | 3100 | Impact resistance forging dies,hot-press forging dies and rollers. | |||

| YG20C | 13.5 | 83.5 | 3300 | Dies for wear resistant or impact resistant application. | |||

| YG22C | 13.3 | 83 | 3500 | Nut forming dies and high impact resistance forging dies. | |||

| YG25C | 13.1 | 82.5 | 3600 | Stainless bolt header dies and rollers. | |||

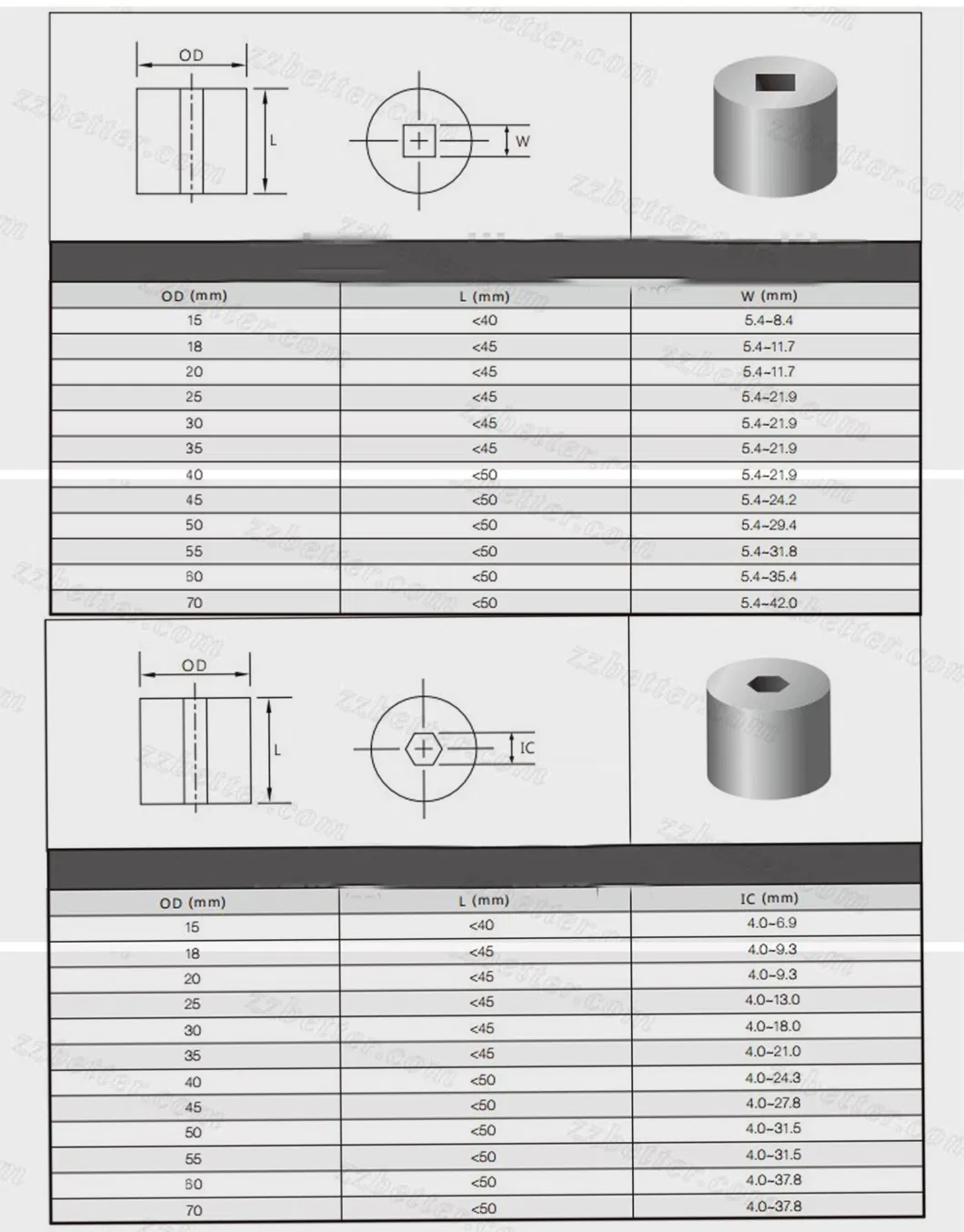

Also we can produce the carbide die as your required.