- Overview

- Product Description

- After Sales Service

Basic Info.

Product Description

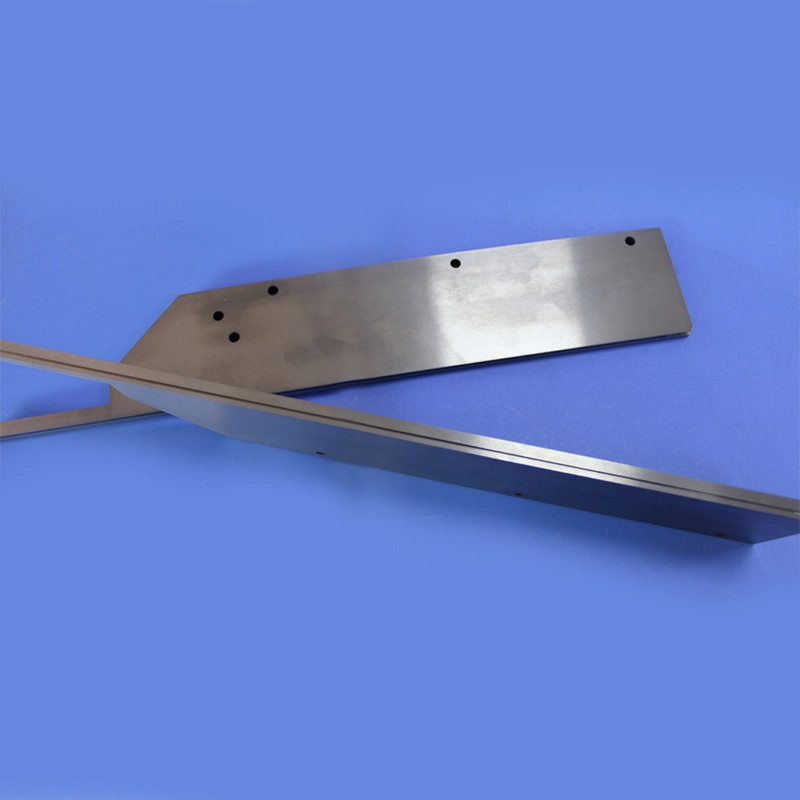

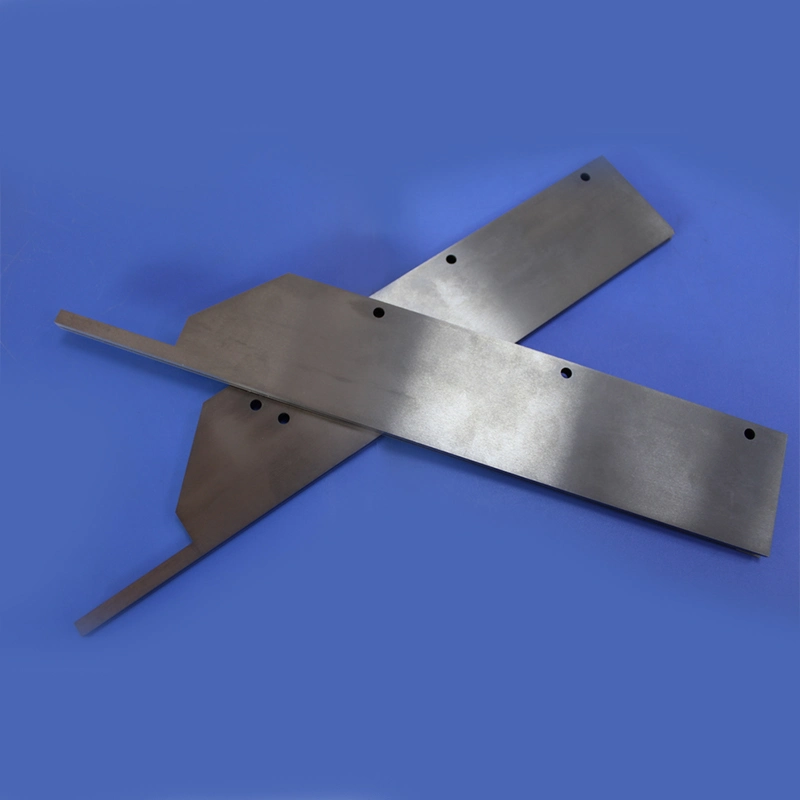

High-Hardness Tungsten carbide Non-Magnetic Feeder Guide Block

We specialize in the production of Tungsten carbide non-magnetic feeder guide blocks, designed as ultra-hard metal components. Typically, Tungsten carbide possesses weak magnetism, but for special requirements, we provide non-magnetic Tungsten carbide parts, suitable for mechanical equipment used in the production and processing of magnetic products such as magnets, magnetic devices, and magnetic components.

Product Features:

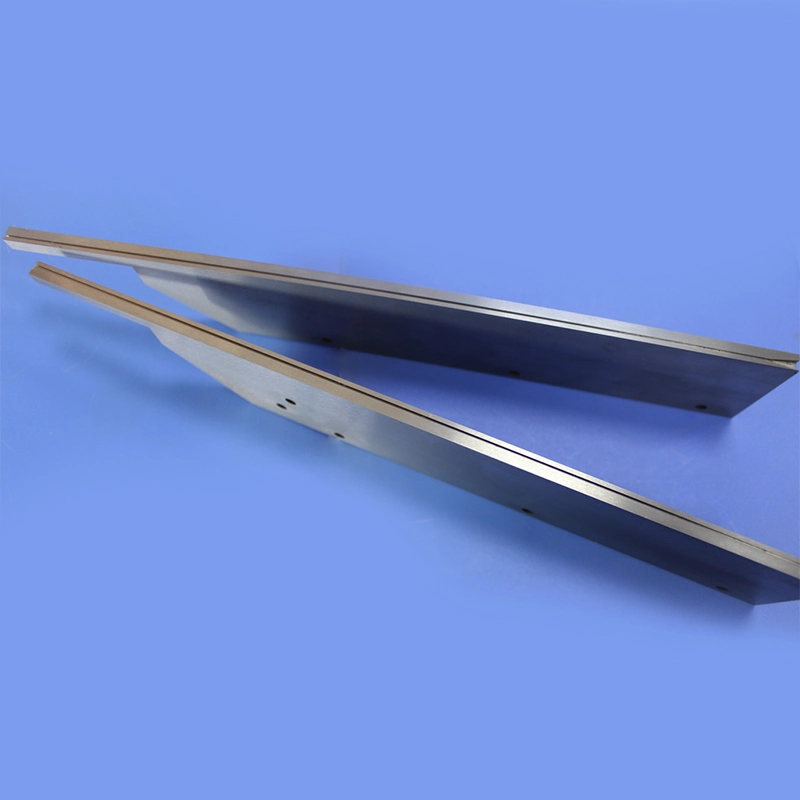

- Non-Magnetic Material: Crafted from non-magnetic Tungsten carbide, ensuring the absence of magnetism, meeting the requirements for the production of magnetic products.

- Superior Performance: Substituting non-magnetic Tungsten carbide for traditional non-magnetic steel enhances the performance of the mold, including hardness and service life.

- Precision Customization: Precision custom production according to customer drawings, ensuring dimensional accuracy and surface quality.

- Specialized Grinding Wheel Processing: Some components require specialized grinding wheel processing to ensure the precision and quality of the straight groove.

- Non-Magnetic Tungsten carbide Feeder Guide Block Top: 284*48.8-10-16°*6*0.9-1.5*Φ4.4-3;

- Non-Magnetic Tungsten carbide Feeder Guide Block Bottom: 284*48.8-10-10°*6*0.9-1.5*Φ4.4-5.

Application Field: This Tungsten carbide machined non-magnetic feeder guide block belongs to the LS-HCT03R DCR testing fixture, used in the production of magnetic material products, including magnets and magnetic components.

Customization Services: We offer precision customization services, producing various non-magnetic tungsten carbide parts, including guide seats, injection hole seats, fixed mold core cores, inclined molding seats, outer diameter core rings, guide blocks, stirring needles, and non-magnetic Tungsten carbide feeder guide blocks. The dimensional tolerance meets ±0.002, and production and processing are carried out according to customer equipment drawings.

We are committed to providing high-performance, high-precision non-magnetic tungsten carbide parts to meet your special requirements in the production of magnetic products.

Technical Support and Services for Tungsten Carbide Processing

We provide technical support and services to ensure that our customers are able to use Tungsten Carbide Processing to its fullest potential. Our experienced and knowledgeable team can provide customized solutions and advice to help you get the most out of your product.

- Product installation and setup

- Troubleshooting and bug fixes

- Product training and tutorials

- On-site support and maintenance

- Software updates and upgrades

- 24/7 customer service