Basic Info.

Product Description

| Product Name | Mold Inserts |

| Materials | 45#,S50C,CR12/CR12MOV,SKD11,DC53,SKH-9,SKH-51,SKH-55, ASP23, ASP30, ASP60, CD650, 2210, YG15, YG8, V30, KD20 etc |

| Standard | Standard Hardware/ Plastic Parts as per MISUMI, DME, HASCO, FIBRO, CUMSA, STRACK, DAYTON NON-Standard parts can be designed or made customized |

| Hardness | HRC58-60,HRC64-66,HRC88-90, or customized |

| Tolerance | ±0.001mm |

| Heat treatment method | High frequency quenching, vacuum heat treatment, quenching and tempering treatment |

| Surface treatment method | Black-plated titanium | Yellow-plated titanium | Chrome-plated | Nickel-plated | P-Tride™ | P-Wear™ | P-Wear Extreme™ | MoST™ | Alcrona™ | TiN | TiCN | TiAIN Balinit C | Electroless Nickel | CrN |

| Service | Customized OEM |

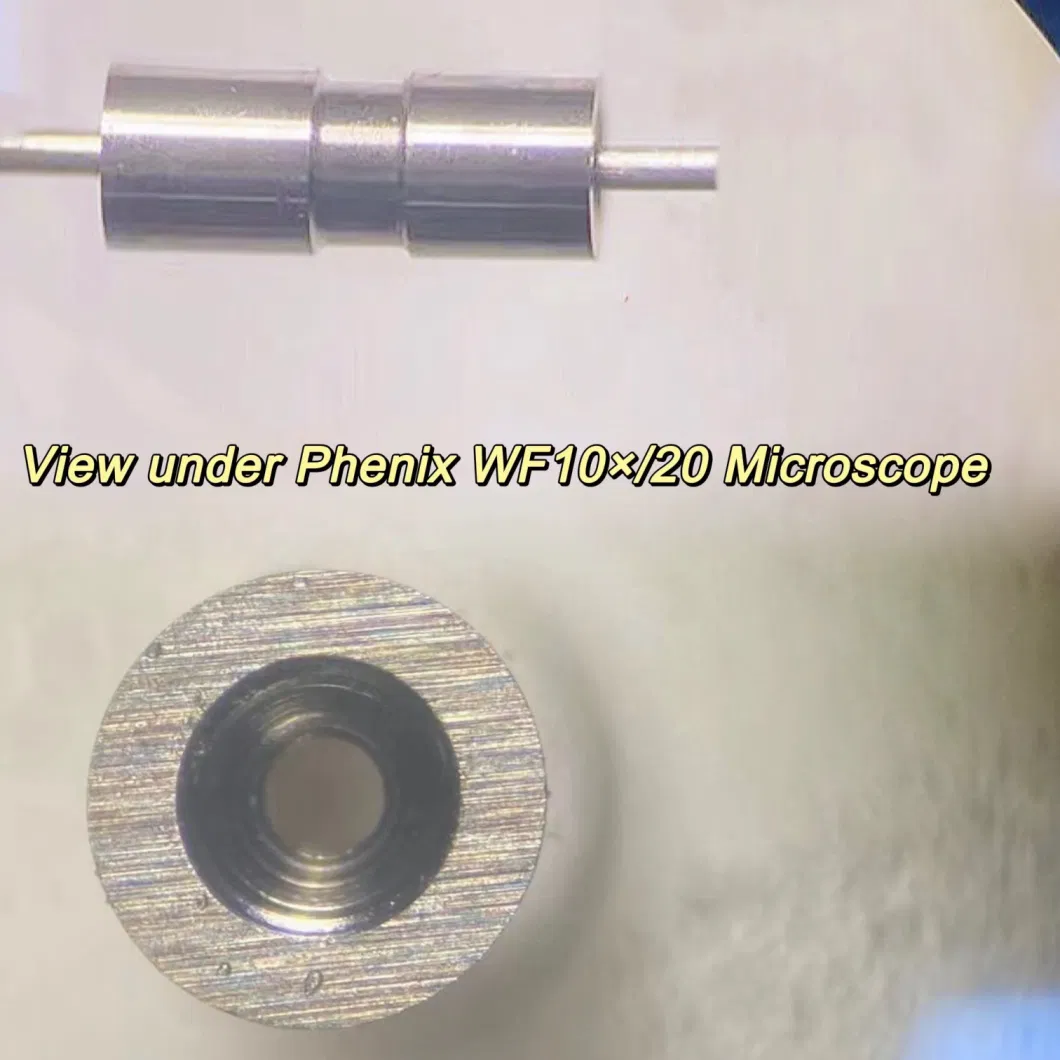

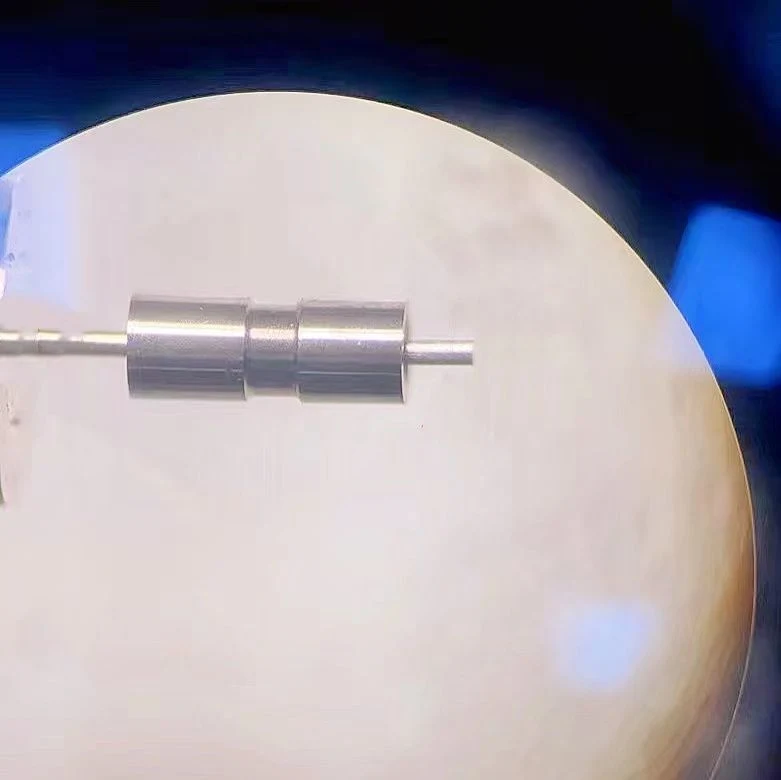

This super small precision bushing is specially designed for micro injection molds, significantly extending the service life of molds. Made of pure tungsten KG7 material, it is finely machined with precise dimensions - 1mm OD, 2.54mm length and only 0.26mm bore size. The ultra-hardness of HRC 62-65 ensures excellent structural stability.

Our company has integrated capabilities of material selection, high-precision cutting, fine machining, and assembly for micro tungsten carbide components. We specialize in the precision processing of various minute bushings, sleeves, nozzle tips to perfectly fit the interior structures of molds. Customized designing and fabrication services are available for ejector pin bushings, guide bushings, sprue bushings, etc. specific to your special process requirements. Please contact us for tailor-made solutions!

Please contact our engineering staff about your custom accessory requirements. We have the capability to manufacture various sleeves, bushings and other accessories specially designed for your molds/dies no matter how complex or precise the specifications. Request a personalized quote today!

Detailed Photos

Lead Time

Sampling: 7-10 workdays

Normal making: 5-12 workdays

Complex design/making: 15-20 workdays

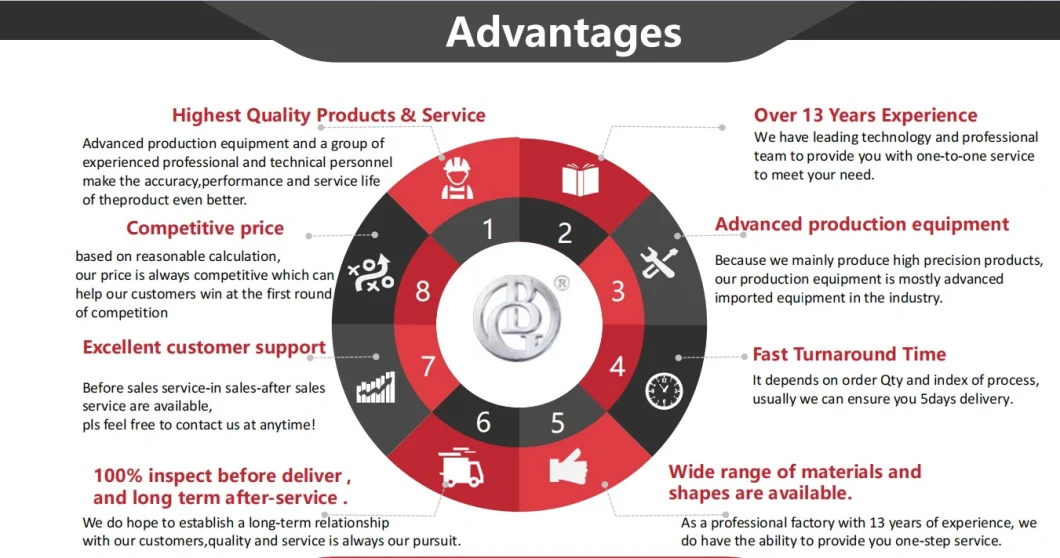

Our Advantages

Consistent Quality Control:

1.We have very experienced staffs can control the parts to exact dimensions in the process of production.

2.Our experienced QCs inspect all the parts thoroughly which can ensure 100% high quality products sent to you .

3. Quick delivery time:

it depends on order Qty, usually we can ensure you 6days delivery

4. Made-to-order service available:

except standard parts like in HASCO,MISUMI,DME,MOELLER, DAYTON,FIBRO, MEUSBURGER,DIN,ISOetc, also we can make special parts which depends on customers detailed requirements.

5. Excellent customer support:

before sales service-in sales-after sales service are available, please feel free to contact us at anytime,we will best service with you!

6. Competitive price:

based on reasonable calculation, our price is always competitive which can support customers at the first round of competition,can help customers save the inquire time.

Q:Are you trading company or manufacture?

A:We are manufacture/factory.Q:What Will You Do After Sales?

A:We have after-sales servise, when you received our products,we will follow up and await your feedback. Any question related to our products,our experienced engineers are always here for backup.

Q: How Do You Ship The Goods And How Long Does It Take To Arrive?

A:Ship by DHL, UPS, FedEx or TNT. It takes 3-5 days to arrive. Airline and sea shipping also optional. Or you can provide your forworder's information,we can contact with them to arrange the shipment.

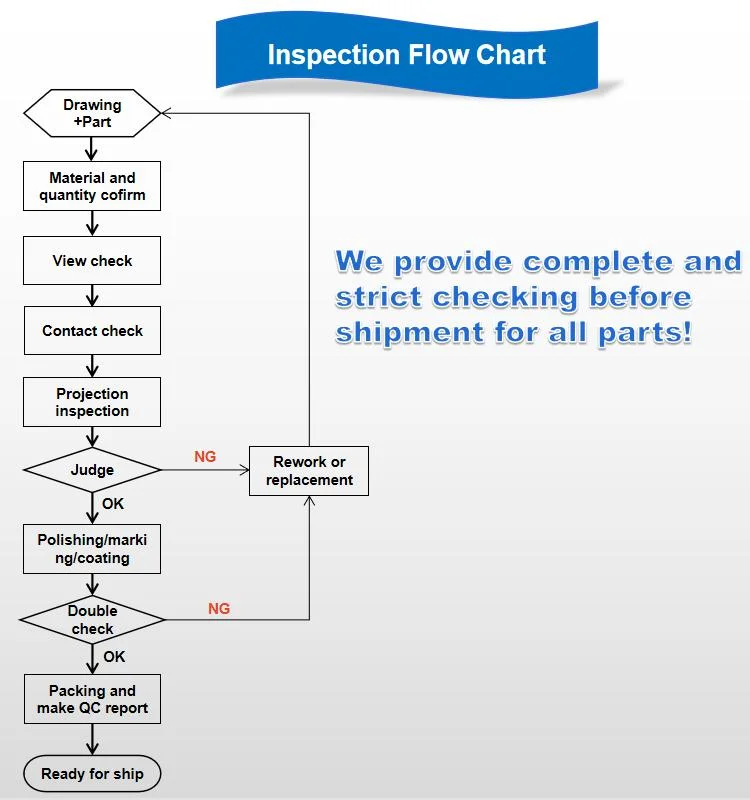

Q: Before Shipment How To Make Sure The Mould Parts Quality?

A:You can come to our factory or let the third party for inspection, if not, we will be as your inspection worker. we will share you a video for production process details.

Q: How To Proceed An Order For Mould Parts?

A:1. let us know your requirements or application.

2. We quote according to your requirements or our suggestions.

3. Customer confirms the samples and paid the deposit for formal order.

4.We arrange the production.

Q: What About The Lead Time?

A:Normally it'll take 3-5 days for Sample preparing ,8-10 working days for mass production. but it also depend on your request and order quantity.

Q: What Type Of Material Is Best For My Design/Component?

A:Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q: I Have An Idea For A New Product, But Don't Know If It Can Be Manufactured. Can You Help?

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q: Do You Have Any MOQ Limit For Led Light Order?

A:Low MOQ, 1pc for sample checking is available. If custom styles, Ipc is ok, we'll do whatever we can to help you realized you ideas.