- Overview

- Product Description

Basic Info.

Model NO.

JFW0140mesh-3

Size

5-10mesh, 10-15mesh, 10-20mesh

Standard 2

ISO9001:2015

HS

8101100010

Product Color

Gray

Transport Package

Packed in Bucket on Plate, Inner Plastic Bags

Specification

20-50kg per bucket

Trademark

XINPAI

Origin

Qingdao China

HS Code

810110000

Production Capacity

1000ton/Year

Product Description

Coarse crystalline tungsten powder

Product introduction:

Purpose:

Used for heavy alloys, electrical contact materials, catalysts, pigments, solid lubricants

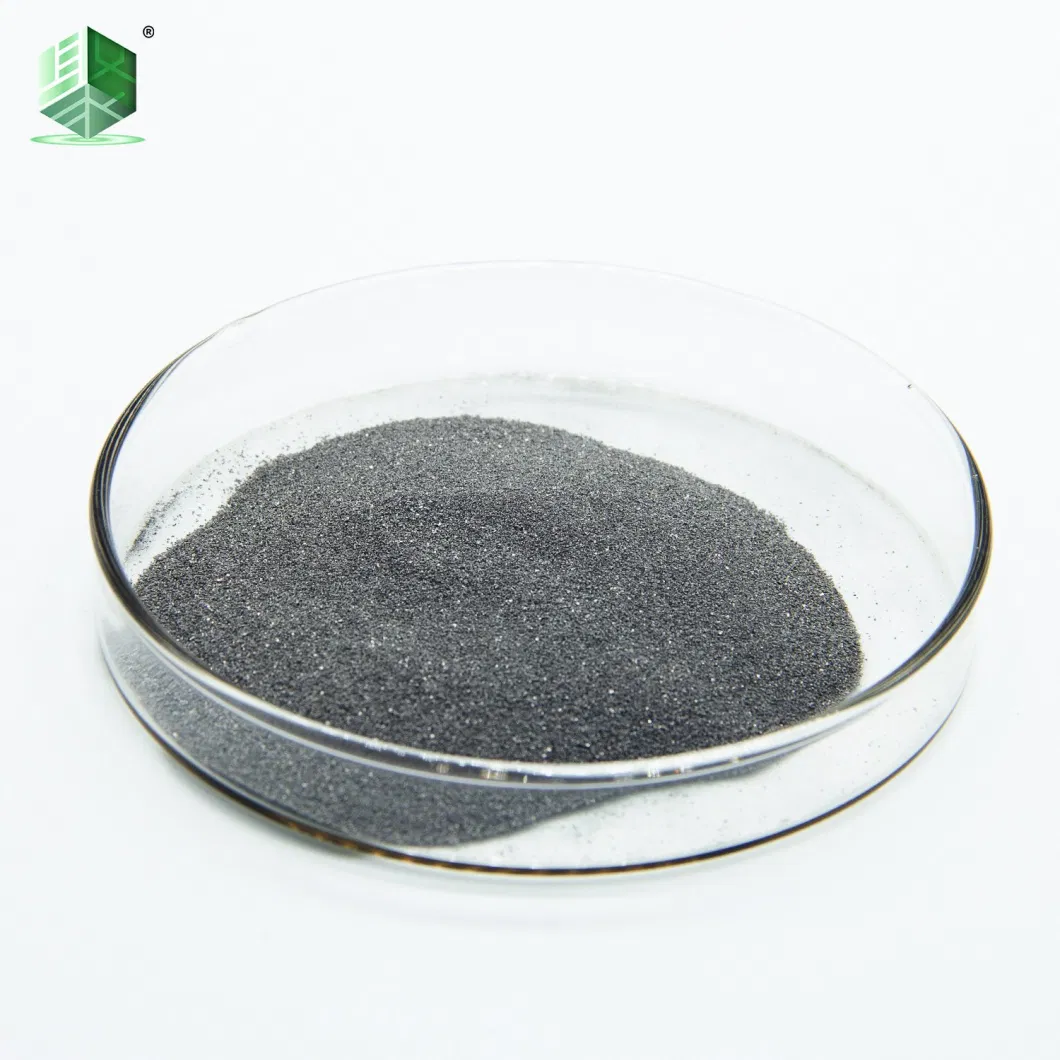

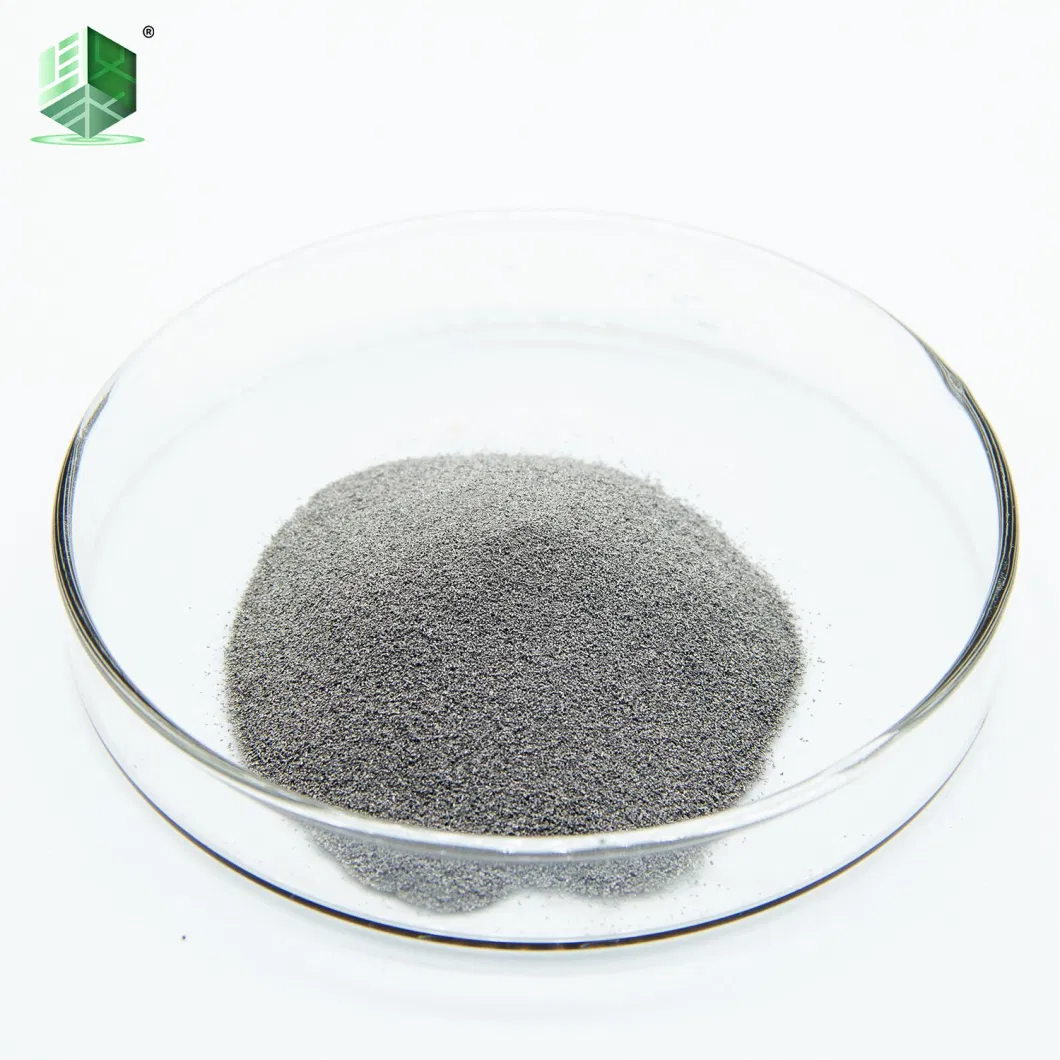

Appearance: tungsten powder is dark gray, and tungsten powder for spraying is bright gray.

Application: For large slab, tungsten rhenium thermocouple raw material, contact alloy, etc.

Packaging: iron bucket, polyethylene double layer plastic bag is built in.

Net weight: each barrel weighs 50kg, 100kg and 200kg. Tungsten is a non-ferrous metal and an important strategic metal manufacturing process:

Tungsten powder is made of tungsten oxide and recovered in a four tube muffle furnace or a multi tube furnace, with the particle size ranging from 0.6-30 microns. Mainly divided into coarse, medium and fine particle sizes, silver gray powder, and impurity content is based on national standards. Use of tungsten powder: mainly used for tungsten materials and tungsten metallurgical materials. Tungsten powder is made of tungsten oxide and recovered in a four tube muffle furnace or a multi tube furnace, with the particle size ranging from 0.6-30 microns. Mainly divided into coarse, medium and fine particle sizes, silver gray powder. The impurity content is based on the national standard. The preparation method is hydrogen reconstituted tungsten trioxide or ammonium paratungstate. The process of preparing tungsten powder by hydrogen recovery is generally divided into two stages: the first stage is that tungsten trioxide is recovered to tungsten dioxide at 500~700oC; In the second stage, tungsten dioxide is recovered into tungsten powder at 700~900oC.

1. Tungsten powder has high purity, uniform particle size and good dispersion. It is an important raw material for the production of tungsten carbide powder

Tungsten carbide powder is the main raw material for processing cemented carbide and has more excellent properties.

2. Tungsten powder not only has high hardness, but also has the characteristics of wear resistance, corrosion resistance and high temperature resistance.

3. The melting point of tungsten is 3400 ºC. Boiling point 5555 ºC, insoluble in water, strong acid and alkali resistance.

Purpose:

Used for heavy alloys, electrical contact materials, catalysts, pigments, solid lubricants

Appearance: tungsten powder is dark gray, and tungsten powder for spraying is bright gray.

Application: For large slab, tungsten rhenium thermocouple raw material, contact alloy, etc.

Packaging: iron bucket, polyethylene double layer plastic bag is built in.

Net weight: each barrel weighs 50kg, 100kg and 200kg. Tungsten is a non-ferrous metal and an important strategic metal manufacturing process:

Tungsten powder is made of tungsten oxide and recovered in a four tube muffle furnace or a multi tube furnace, with the particle size ranging from 0.6-30 microns. Mainly divided into coarse, medium and fine particle sizes, silver gray powder, and impurity content is based on national standards. Use of tungsten powder: mainly used for tungsten materials and tungsten metallurgical materials. Tungsten powder is made of tungsten oxide and recovered in a four tube muffle furnace or a multi tube furnace, with the particle size ranging from 0.6-30 microns. Mainly divided into coarse, medium and fine particle sizes, silver gray powder. The impurity content is based on the national standard. The preparation method is hydrogen reconstituted tungsten trioxide or ammonium paratungstate. The process of preparing tungsten powder by hydrogen recovery is generally divided into two stages: the first stage is that tungsten trioxide is recovered to tungsten dioxide at 500~700oC; In the second stage, tungsten dioxide is recovered into tungsten powder at 700~900oC.

1. Tungsten powder has high purity, uniform particle size and good dispersion. It is an important raw material for the production of tungsten carbide powder

Tungsten carbide powder is the main raw material for processing cemented carbide and has more excellent properties.

2. Tungsten powder not only has high hardness, but also has the characteristics of wear resistance, corrosion resistance and high temperature resistance.

3. The melting point of tungsten is 3400 ºC. Boiling point 5555 ºC, insoluble in water, strong acid and alkali resistance.

4.The hardness of tungsten is the hardest among metals. The hardness of sintered tungsten rod is 200 ~ 250 and that of tungsten rod passing through rotary hammer is 350 ~ 400.

| W | Fe | Si | Ai | Ca | Ni | Mg | C | O |

| >99.9% | 0.005 | 0.002 | 0.005 | 0.001 | 0.002 | 0.001 | 0.005 | 0.05 |